Wilo-CronoTwin-DL

Wilo-CronoTwin-DL

Your advantages

- Reduced life cycle costs through optimised efficiency

- Can be used flexibly in air-conditioning and cooling systems, with application benefits due to direct draining of condensate via optimised lantern design (patented)

- High standard of corrosion protection thanks to cataphoretic coating

- Main/standby mode or peak-load operation (by means of external auxiliary device)

Recommended services

CronoTwin-DL

Design

Glanded twin-head pump in in-line design with flange connection

Application

Pumping of heating water (acc. to VDI 2035), chilled water and water/glycol mixtures without abrasive substances in heating, chilled water and cooling systems.

Typekey

Example | DL 40/160‐4/2 |

DL | In-line double pump |

40 | Nominal diameter DN of the pipe connection |

160 | Nominal impeller diameter |

4 | Rated motor power P2 in kW |

2 | Number of poles |

Technical data

- Permissible temperature range -20 °C to +140 °C

- Mains connection 3~400 V, 50 Hz (others on request)

- Protection class IP 55

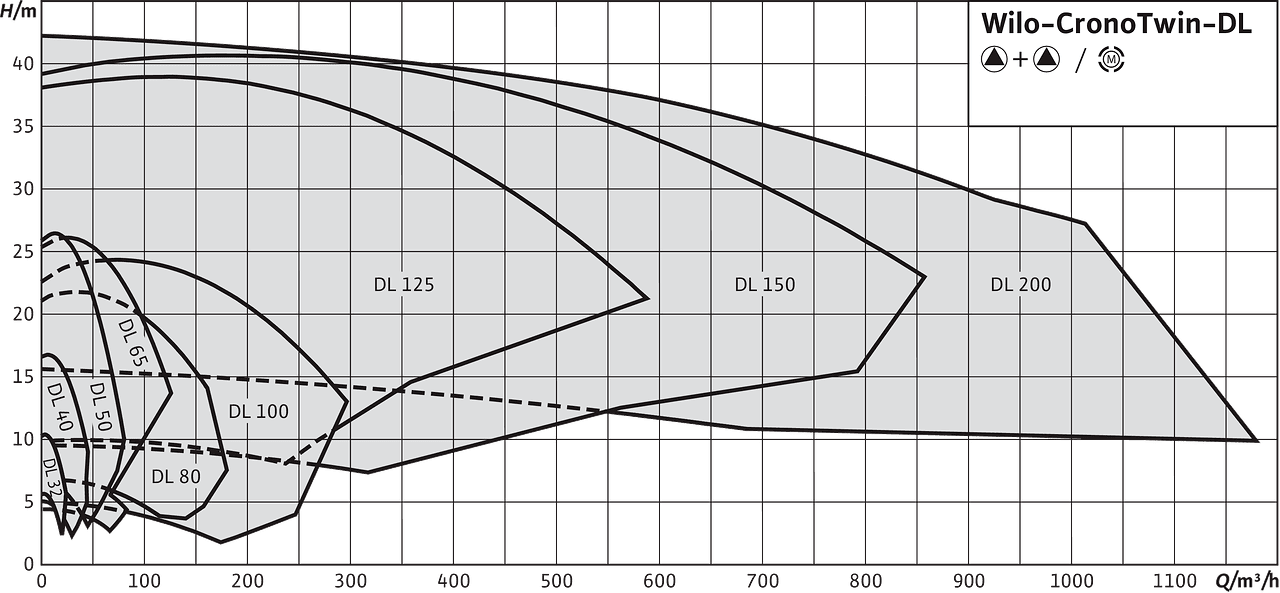

- Nominal diameter DN 32 to DN 200

- Max. operating pressure 16 bar

Materials

- Pump housing and lantern: Standard: EN-GJL-250

- Impeller: Standard: EN-GJL-200; special version: Bronze CuSn 10

- Shaft: 1.4122

- Mechanical seal: AQEGG; other mechanical seals on request

Construction

Single-stage, low-pressure double pump in in-line design with

- Switchover valve

- Mechanical seal

- Flange connection with pressure measuring connection R 1/8

- Lantern

- Coupling

- IEC standard motor

Scope of delivery

- Pump

- Installation and operating instructions

Options

- ...-L1 variant with bronze impeller (at additional charge)

- Other voltages and frequencies as well as ATEX approval on request

Accessories

- Mounting brackets for installation on a base

- PTC thermistor sensor, PTC resistor tripping relay

- Special motors

- Special mechanical seals

- SC-HVAC, CC-HVAC control systems and switchgears

- Blind flanges

Installation and operating instructions

Wilo-Wilo-CronoLine-IL Wilo-CronoTwin-DL Wilo-CronoBloc-BL

| Article Number | 2202024 |

| Edition | 2018-07 |

| Number of pages | 128 |

| Language | de, en, fr, nl |

Consulting manual

Glanded pumps, single-stage, single-volute

| Article Number | Wilo515021 |

| Edition | 2021-12 |

| Number of pages | 24 |

| Language | en |

Certification booklet

Wilo-CronoLine-IL-E, Wilo-CronoTwin-DL-E, Wilo-CronoBloc-BL-E, Wilo-Atmos GIGA-I/-B, Wilo-CronoLine-IL, Wilo-CronoTwin-DL, Wilo-CronoBloc-BL

| Article Number | 2216677 |

| Edition | 2022-11 |

| Number of pages | 40 |

| Language | language neutral |

Reference sheet

Reference Sheet (English) - Power industry - Power Station Anpara, Anpara, India, 2014

| Number of pages | 2 |

| Language | en |