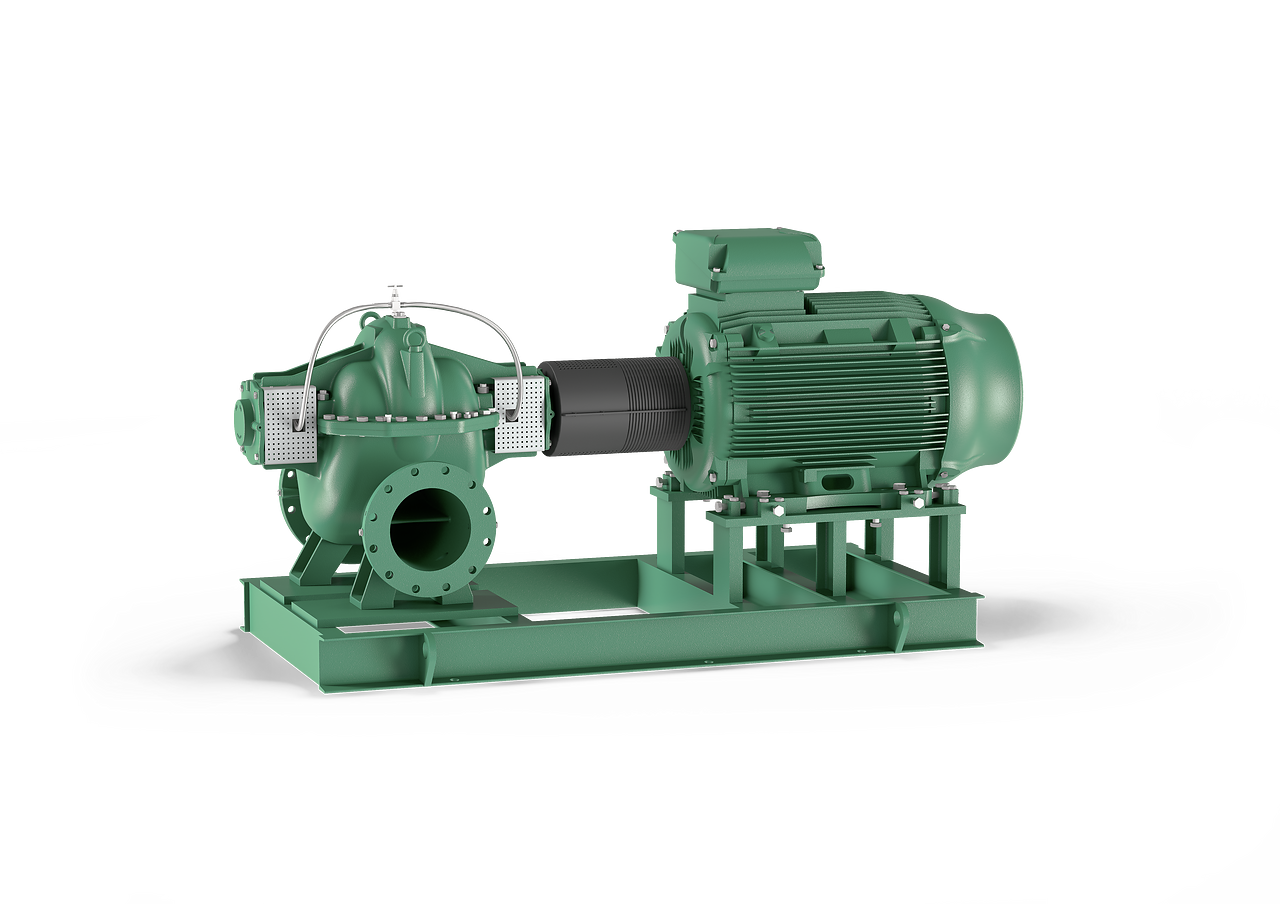

Wilo-Atmos TERA-SCH

Pumpa s aksijalno podijeljenim kućištem za pouzdan pogon i energetski učinkovit transport velikih količina protoka rasprostranjenim distribucijskim sustavima.

Wilo-Atmos TERA-SCH

Pumpa s aksijalno podijeljenim kućištem za pouzdan pogon i energetski učinkovit transport velikih količina protoka rasprostranjenim distribucijskim sustavima.

Pumpa s aksijalno podijeljenim kućištem Wilo-Atmos TERA-SCH služi za pouzdanu opskrbu vodom 365 dana godišnje i to s malim pogonskim troškovima. Dizajn lagan za održavanje kao i visoki stupanj iskorištenja u cjelokupnom području krivulje osiguravaju energetski učinkovit pogon sa smanjenim trošenjem te pridonose konstantnoj opskrbi vodom.

Preporučene servisne usluge

Osobitosti / prednosti proizvoda

- Pouzdan trajni pogon za učinkovitu opskrbu pitkom vodom u rasprostranjenim cjevovodima - točno individualno prilagođavanje prema vašim zahtjevima

- Smanjivanja troškova energije visokim ukupnim stupnjem iskorištenja

- Pojednostavljenje i smanjivanje centriranja zahvaljujući tolerantnoj spojki i sustavu za namještanje motora

- Povećana sigurnost pri radu zahvaljujući tihoj hidraulici s neznatnim vibracijama i niskom razinom buke

- Smanjena sklonost kavitaciji optimiziranim NPSH postupcima

- Zahvaljujući kompaktnoj izvedbi zahtijeva malo prostora

- Dostupno i kao certificirana izvedba pitke vode

- Opcionalno raspoloživo sa zaštitnim premazom Ceram-CT - za do 3 % povećanja učinkovitosti

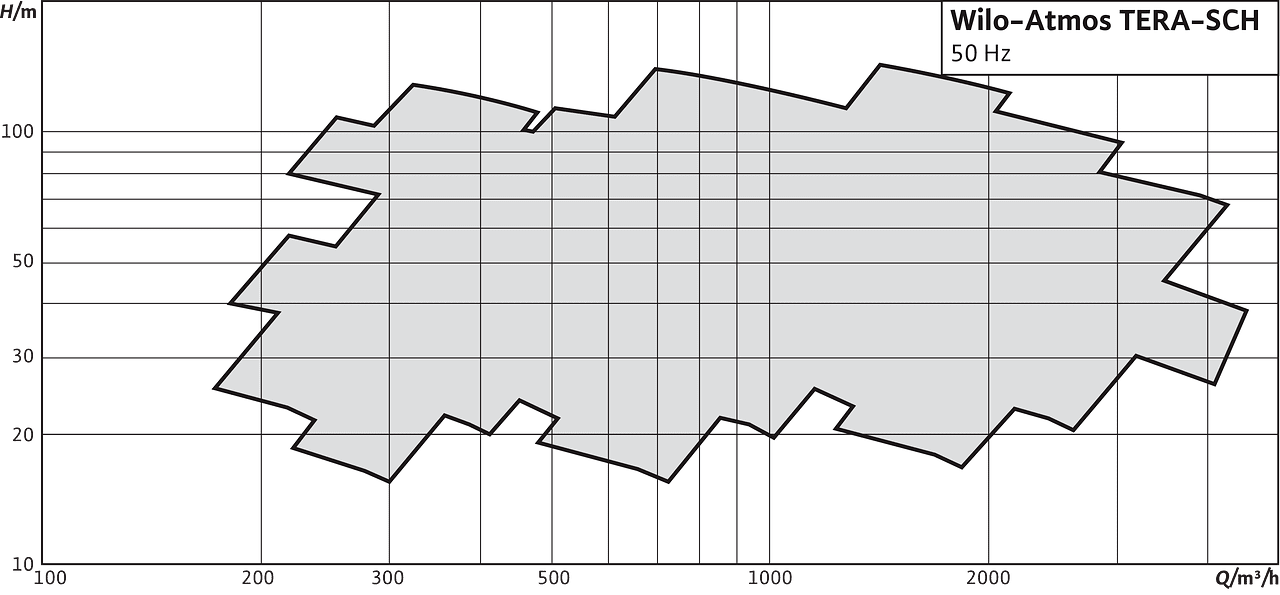

- Do 4500 m³/h standardnog nivoa količina protoka

Wilo-Atmos TERA-SCH

Konstrukcija

Pumpa s aksijalno podijeljenim kućištem instalirana na osnovni okvir

Primjena

- Trošenje neobrađene vode, povišenje tlaka i opći transport u elektranama, vodovodima i komunalnim mrežama za opskrbu pitkom vodom

- Opskrba rashladnom i potrošnom vodom u elektranama i industrijskim postrojenjima

- Navodnjavanje u komercijalnoj poljoprivredi

- Transportiranje ogrjevne vode (u Njemačkoj prema normi VDI 2035) i mješavine vode/glikola

Ključ tipa

Primjer | Atmos TERA-SCH 250/360-75/4-L1 |

Atmos | Skupina proizvoda |

TERA | Oznaka serije |

SCH | Pumpa s aksijalno podijeljenim kućištem, vodoravna |

250 | DN za tlačnu prirubnicu |

360 | Nazivni promjer radnog kola [mm] |

75 | Nazivna snaga motora P2 [kW] |

4 | Broj polova |

L1 | Kod varijanti (L1 = bronca - radno kolo) |

Tehnički podatci

- Temperatura medija: od -20 °C do +120 °C

- Mrežni priključak 3~400 V, 50 Hz

- Nazivni promjeri

- s usisne strane: od DN 150 do DN 600

- s tlačne strane: od DN 125 do DN 450

- Maks. radni tlak: PN 10, PN 16

Materijali

- Kućište pumpe: EN-GJL-250

- Radno kolo: EN-GJL-250 / G-CuSn10 / GX5CrNiMo19-11-2

- Vratilo: X12Cr13

Konstrukcija

- Centrifugalna pumpa s aksijalno podijeljenim kućištem, raspoloživa u jednostupanjskoj izvedbi

- Isporuka u vidu kompletnog agregata (pumpa sa spojkom, zaštitom spojke, motorom i pločom postolja) odn. bez motora ili samo hidraulika pumpe

- Brtvljenje vratila klizno-mehaničkom brtvom ili paketom brtvenica

- Dvopolni, četveropolni i šesteropolni motori; IE3 standardni nivo do 1000 kW (IE4 na upit)

- Zavareni čelični okvir

Opseg isporuke

- Pumpa sa slobodnim krajem vratila ili spojkom ili kao kompletni agregat

- Upute za ugradnju i uporabu