Wilo-Yonos GIGA-N

The standard pump for universal applications and high energy efficiency.

The standard pump for universal applications and high energy efficiency.

The Wilo-Yonos GIGA-N is a pump with high energy efficiency for use in heating, air conditioning and cooling applications in buildings with high delivery heads that require the movement of large volumes of water.

Recommended services

Your advantages

- Efficient pump thanks to the use of IE4 motors

- Cataphoretic coating of all cast components for high resistance to corrosion and long service life

- Standard dimensions in accordance with EN 733 make the pump universally deployable

- Easy adjustment and operation with Green Button Technology

- Easy maintenance thanks to user-friendly spacer coupling in back pull-out design

- Optional interfaces for connection to building automation using insertable IF modules

Design

Electronically controlled, single-stage low-pressure centrifugal pump with axial suction. Mounted on a baseplate with flange connection and automatic power adjustment.

Application

- The pumping of heating water (in accordance with VDI 2035), chilled water and water-glycol mixtures without abrasive substances in heating, chilled water and cooling systems.

- Applications for irrigation, building services, general industry, power stations, etc.

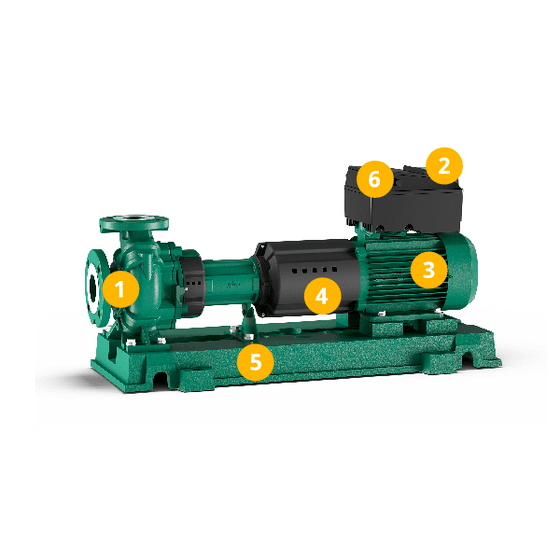

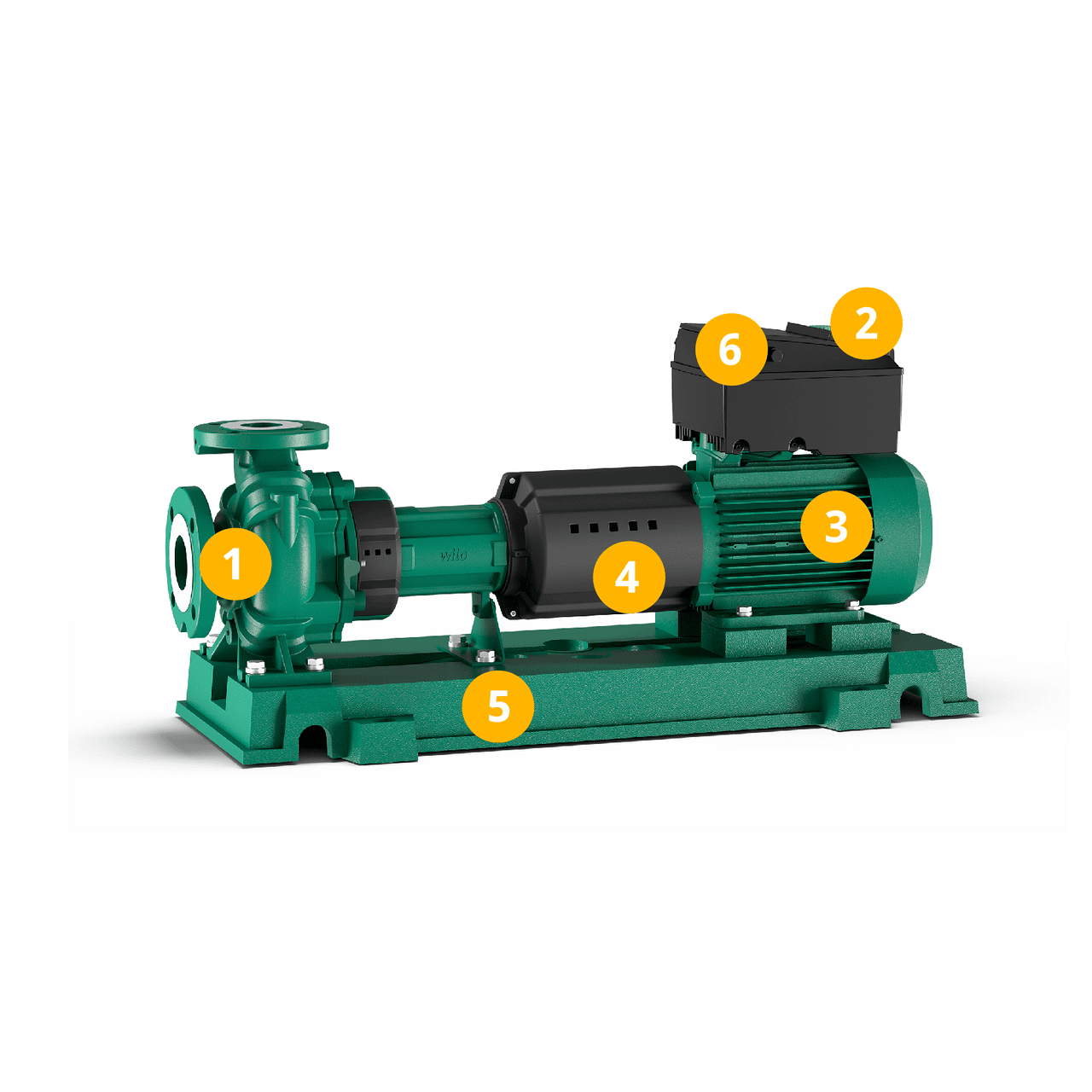

Equipment/function

Single-stage low-pressure centrifugal pump in monobloc design with coupling, coupling guard, motor and baseplate

- Drive with integrated electronic speed control

- Mechanical seal

Operating modes

- Δp-c for constant differential pressure

- PID-Control

- Constant speed (n=constant)

Manual operation level

- Green button and display

Manual functions

- Differential pressure setpoint setting

- Setting the speed (manual control mode)

- Setting the operating mode

- Setting the pump ON/OFF

- Configuration of all operating parameters

- Fault acknowledgement

External control functions

- "Overriding Off" control input

- Analogue input 0 – 10 V, 0 – 20 mA for constant speed (DDC) and remote setpoint adjustment

- Analogue input 2 – 10 V, 4 – 20 mA for constant speed (DDC) and remote setpoint adjustment

- Analogue input 0 – 10 V for actual value signal from pressure sensor

- Analogue input 2 – 10 V, 0 – 20 mA, 4 – 20 mA for actual value signal from pressure sensor

Signal and display functions

- Collective fault signal SSM

- Collective run signal SBM

Data exchange

- Infrared interface for wireless data exchange with IR-Monitor/IR-Stick

- Plug-in position for Wilo IF-Modules (Modbus, BACnet, CAN, PLR, LON) for connection to building automation

Safety functions

- Full motor protection with integrated trip electronics

- Access disable

Dual pump management (2 x single pump; Y-piece application only)

- Main/standby operation (automatic fault-actuated switchover)

- Pump cycling main/standby operation after 24 hours

- Parallel operation

Typekey

NO VALUE |

Technical data

- Fluid temperature -20 °C to +140 °C

- Mains connection

- 3~440 V ±10 %, 50/60 Hz

- 3~400 V ±10 %, 50/60 Hz

- 3~380 V -5/+10 %, 50/60 Hz

Compliance with electromagnetic compatibility without additional measures:

- Interference emission for residential environment according to EN 61800-3:2018

- Interference immunity for industrial environments according to EN 61800-3:2018

- Protection class IP55

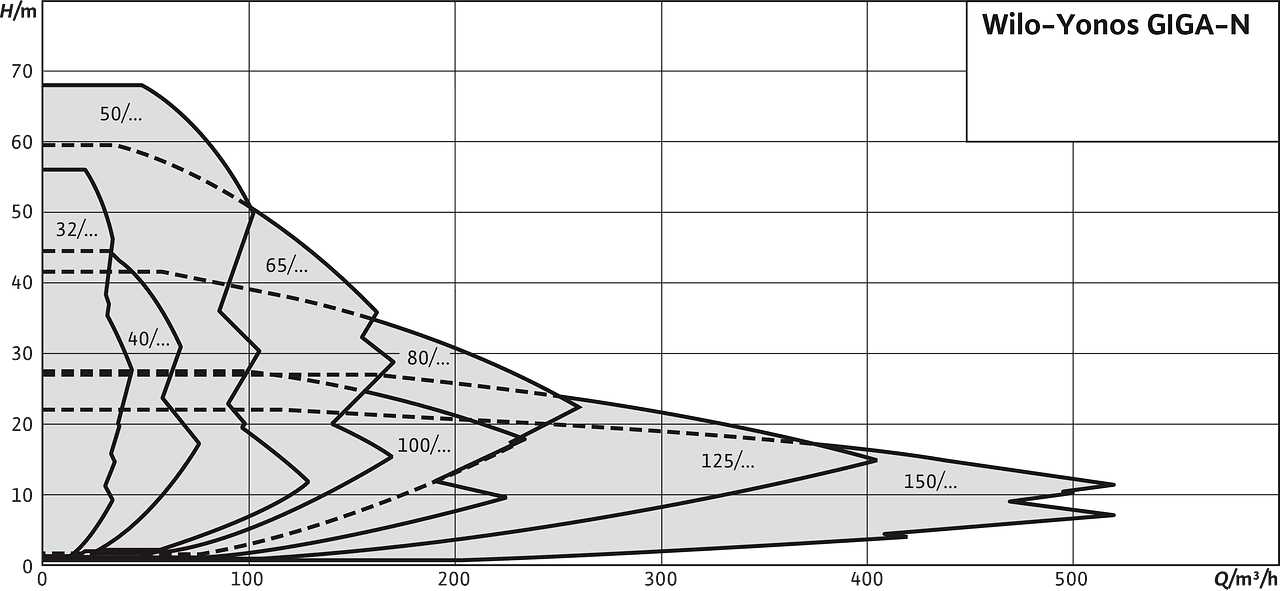

- Nominal diameter DN 32 to DN 150

- Max. operating pressure 16 bar

Materials

- Pump housing and lantern. Standard: EN-GJL-250

- Impeller: Standard: EN-GJL-200; others on request

- Shaft: 1.4021

- Mechanical seal: AQEGG; other mechanical seals on request

Construction

- Single-stage low-pressure centrifugal pump as baseplate pump with axial suction ports with flanged bearing brackets and axle fastening for flexibly coupled drives

- Drive with integrated electronic speed control

- Spacer coupling (sleeve coupling) is standard; this provides the option of leaving the motor in position when dismantling the rotor unit

- Variant ...-P5 without spacer coupling (at reduced price, see price list)

Scope of delivery

- Pump

- Installation and operating instructions

- Completely mounted pump on baseplate with coupling, coupling guard and electric motor

Options

- ...-L1 variant with bronze impeller (at additional charge)

- …-L4 variant with stainless steel impeller (at additional charge)

- ...-S1/-S2 variant with special mechanical seal (at additional charge)

- Variant ...-P5 without spacer coupling (at reduced price)

Installation and operating instructions

Consulting manual

Glanded pumps, single-stage, single-volute

| Article Number | Wilo515021 |

| Edition | 2021-12 |

| Number of pages | 24 |

| Language | en |

Certification booklet

Wilo-Atmos GIGA-N, Wilo-Yonos GIGA-N

| Article Number | 6088790 |

| Edition | 2021-01 |

| Number of pages | 16 |

| Language | en |