Wilo-Helix2.0-VE

High energy efficiency and user-friendly operation for cold water applications.

High energy efficiency and user-friendly operation for cold water applications.

Wilo-Helix2.0-VE is the new generation of vertical multistage pumps for cold water applications and can be used in a variety of ways. The frequency converter with six control modes, along with the IE5 EC motor, allows for optimal adjustment to a wide range of pressure conditions and volume flows. The result is high energy efficiency in both closed and open systems. The proven Helix stainless-steel hydraulics also offer a high level of operational reliability.

A colour display with clear menu navigation and the familiar Green Button Technology make commissioning and operating the pump easy. It can be integrated into the building automation as required via analogue and digital interfaces as well as CIF modules.

Recommended services

Your advantages

- IE5 EC motor and six integrated control modes (dp-v, dp-c, p-v, p-c, n-const, PID) ensure high energy efficiency

- Various features – such as dry-running detection, automatic PWM frequency reduction, programmable pump kick and secure-operation mode – provide a high degree of operational reliability

- Suitable for ambient temperatures of up to 50 °C

- Green Button Technology and clear menu navigation in the colour display enable easy operation

- Proven pump hydraulics made of stainless steel are very robust

- Ready for integration into building automation via analogue or digital interfaces as well as CIF modules

Eco-friendly features

- High-efficiency pump with IE5 EC motor and with cast- or laser-welded 3D impellers

- Minimisation of energy consumption through various control modes

- Stackable and compact packaging enhances space efficiency during transport

- High recyclability of the complete packaging (>95% of weight)

Design type

Highly efficient, non-self-priming high-pressure multistage centrifugal pump in vertical design with in-line connections, equipped with electronically controlled EC motor of energy efficiency class IE5 in accordance with IEC 60034-30-2.

Application

- Water supply and pressure boosting

- Industrial circulation systems

- Process water

- Closed cooling circuits

- Heating

- Washing systems

- Irrigation

Equipment/function

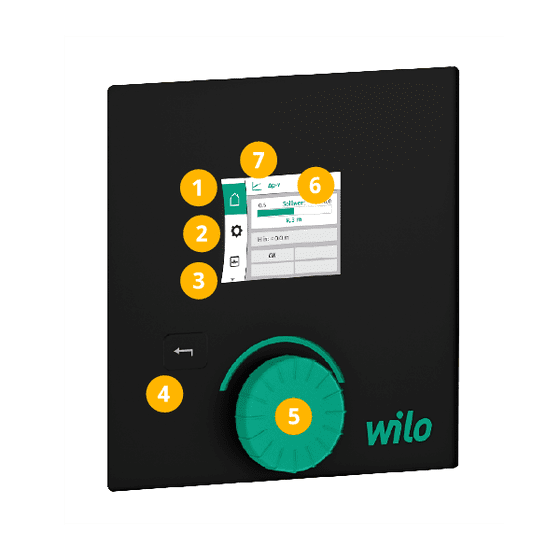

- 2” coloured LCD display

- Wilo Green Button Technology and soft button with return function for menu navigation and pump setting

- Green LED indicates pump status

- Blue LED indicates that pump is influenced externally via an interface

- Impellers, guide vanes and stage housings made of corrosion-resistant material

Operating modes

- Constant pressure p-c

- Variable pressure p-v

- Constant differential pressure ∆p-c

- Variable differential pressure ∆p-v

- Constant speed n-c

- PID control

Analogue input

- IN (AI 1): Input sensor signal 4 ... 20 mA, 0 ... 10 V, 0 ... 20 mA or 2 ... 10 V

- IN (AI 2): Input setpoint 0 ... 20 mA, 0 ... 10 V, 4 ... 20 mA, 2 ... 10 V or input sensor signal 4 ... 20 mA, 0 ... 10 V, 0 ... 20 mA or 2 ... 10 V

Digital input IN (DI 1)

- Extern off

- Lack of water detection by binary input

Functions

- Maximum pressure limit detection

- Minimum pressure limit detection

- Lack of water detection by suction sensor

- Zero flow test (open loop)

- No-Flow Stop (closed loop)

- Dry running detection

- Volume flow calculation by using differential pressure sensor

- Pump kick

- Error and warning codes

- Overload protection

- Access lock

- Plug-in position for Wilo CIF-modules PLR, LON, BACnet MS/TP, Modbus RTU, CANopen, Ethernet Multi-protocol (Modbus TCP, BACnet/IP) for connection to the building automation

Dual pump management (2 x single pumps)

- Main/standby operation

- Pump cycling main/standby operation after 24 hours or automatic fault-actuated switchover

- Wired connection via Wilo Net

Typekey

Example: | Helix2.0-VE 2204/2-1/16/E/KS/3 |

Helix2.0-VE | Vertical high-pressure multistage centrifugal pump in in-line design, electronically controlled |

2 | Flow rate in m3/h |

04 | Number of impellers |

2 | Number of trimmed impellers (optionally) |

1 | Pump material |

1 = Pump housing 1.4301 (AISI 304) Hydraulics 1.4307 (AISI 304L) | |

2 = Pump housing 1.4409 (AISI 316L) Hydraulics 1.4404 (AISI 316L) | |

16 | Maximum operating pressure in bar |

16 = 16 bar (PN 16 flange) | |

25 = 25 bar (PN 25 flange) | |

E | Gasket type E = EPDM V = FKM |

K | Cartridge mechanical seal |

S | The coupling guard is on a line with suction and discharge ports of the pump |

3 | 1 = 1~ (alternating current) |

3 = 3~ (three-phase current) |

Technical data

- Electrical connection:

- 3~ 380 V ... 480 V, ±10 %, 50/60 Hz TN, TT, IT

- Fluid temperature range:

- With EPDM: -30 ... 120 °C (130 °C possible with cartridge and below 16 bar)

- With FKM: -15 ... 90 °C

- Max. operating pressure: 16/25 bar

- IP rating: IP55

- Max. ambient temperature: +50 °C (extended temperature ranges on request)

- Available versions:

- Helix VE 2 – 16: PN 16 with oval flanges, PN 25 with compatible round flanges according to ISO 2531 and ISO 7005 (Victaulic coupling or tri-clamp connection on request)

- Helix VE 22 – 105: PN 16 and PN 25 with round flanges according to ISO 2531 and ISO 7005

Materials

Helix2.0 VE 2, 4, 6, 10, 16:

Pump material combination 1

- Impellers, stage housings and guide vanes made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4301 (AISI 304)

- Baseplate and lantern made of EN-GJL 250 (cataphoretic-coated)

- Shaft made of stainless steel 1.4301 (AISI 304) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring made of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

Pump material combination 2

- Impellers, stage housings and guide vanes made of stainless steel 1.4404 (AISI 316L)

- Pump housing made of stainless steel 1.4404 (AISI 316L)

- Shaft made of stainless steel 1.4404 (AISI 316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring made of FKM (EPDM gasket on request)

- Jacket pipe made of stainless steel 1.4404 (AISI 316L)

Helix2.0 VE 22, 36, 52, 80, 105:

Pump material combination 1

- Stage housings, impellers, guide vanes made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4308 (AISI 304), loose flanges made of cataphoretic-coated cast iron EN-GJL 250 or EN-GJS 400

- Shaft made of stainless steel 1.4057 (AISI 431)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring made of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

Pump material combination 2

- Stage housings, impellers, and guide vanes made of stainless steel 1.4404 (AISI 316L)

- Pump housing: all parts which come in contact with the media are made of cast stainless steel 1.4409 (AISI 316L), loose flanges made of cataphoretic-coated cast iron EN-GJL 250 or EN-GJS 400

- Baseplate made of cataphoretic coated cast iron

- Shaft made of stainless steel 1.4404 (AISI 316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring made of FKM or EPDM

- Pressure shroud made of stainless steel 1.4404 (AISI 316L)

Scope of delivery

- Helix2.0-VE high-pressure multistage centrifugal pump

- Installation and operating instructions

- Helix2.0-VE 2 – 16 (version PN16 with oval flanges): Counter flanges made of stainless steel with corresponding screws, nuts and gaskets

- Anti-vibration accessory kit with specific washers and screws (only for some models Helix2.0-VE 2 – 16 ≥ 2.2 kW)

Accessories

- CIF module PLR for connecting to PLR/interface converter

- CIF module LON for connection to the LONWORKS mains network

- CIF module BACnet

- CIF module Modbus

- CIF module CANopen

- CIF module Ethernet

- Connection M12 RJ45 CIF Ethernet

- Differential pressure kit 4 – 20mA

- Relative pressure kit 4 – 20mA