Wilo’s End-to-End Solution for Data Centers

From server cooling to building services, from design to post-sales service

Efficient energy management and effective heat dissipation control at the core of operating a data center, where countless servers, storage systems, and networking devices generate immense heat.

Wilo's wide range of HVAC solutions, from air cooling to liquid cooling, chillers and more, ensure the reliability, efficiency and sustainability of your data center operations.

Wilo offers pumps and pump systems that are vital to data center infrastructure, from water supply to drainage, delivering complete solutions spanning cooling and facility-wide operations. We also provide solutions based on the entire life cycle, from design to construction/installation and maintenance and repair services.

Wilo’s Sustainable Operation Solution for Data Centers

From optimal cooling technologies to efficient energy management solutions

With over 40% of a data center's energy consumption focused on cooling systems, applying optimal solutions and efficient fluid control techniques are key to sustainable data center operations.

Wilo's data center solution is flexible enough to adapt to next-generation cooling methods, from air cooling to direct?to-chip (DTC) to immersion cooling, and effectively support the reliable operation of your cooling solution.

In addition, Wilo's range of high-efficiency energy technologies and connectivity technologies enable data center operations to be more efficient and optimize energy use.

Wilo's Control Technology for the Future of Sustainable Data Centers

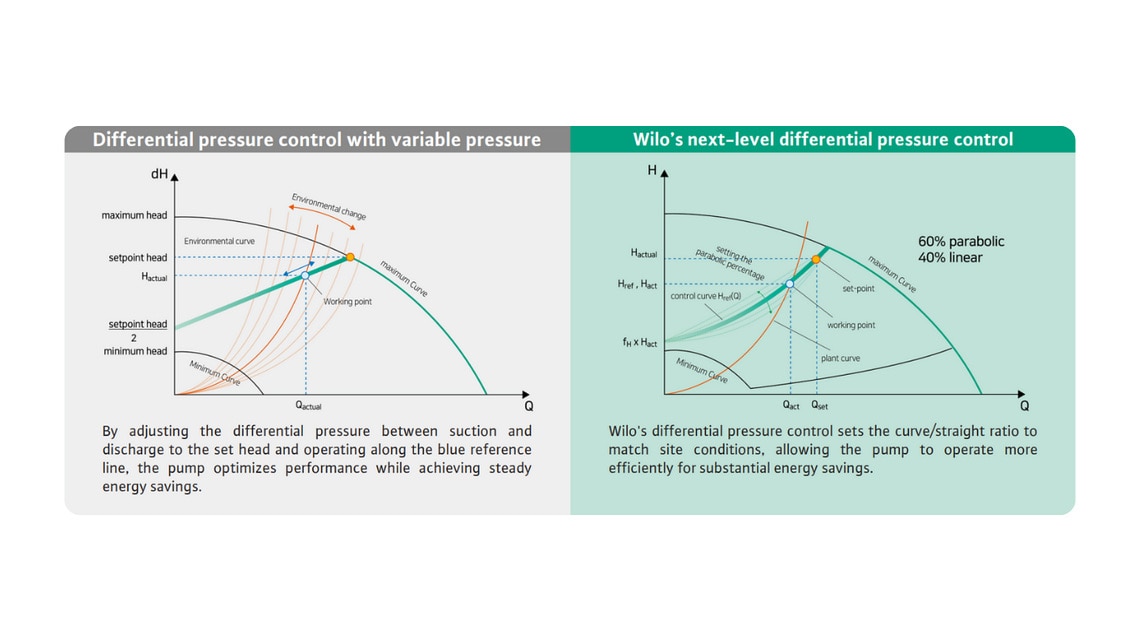

Differential Pressure Control

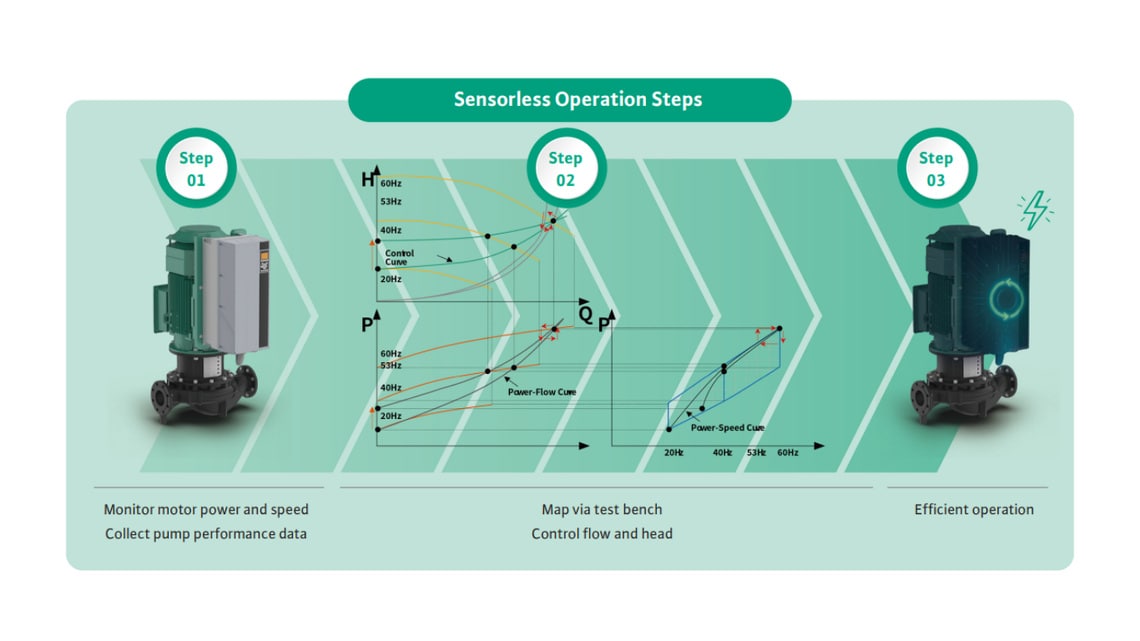

Benefits of sensorless operation

Advantages of Sensorless Operation

-

Energy Savings

- 10–15% reduction compared to constant-speed pumps

-

Cost Reduction

- Lower installation and secondary wiring costs with sensor-integrated inverter models

-

Easy Maintenance

- Easy troubleshooting directly at the pump

-

Simplified Processes

- Simplified commissioning saves time and money

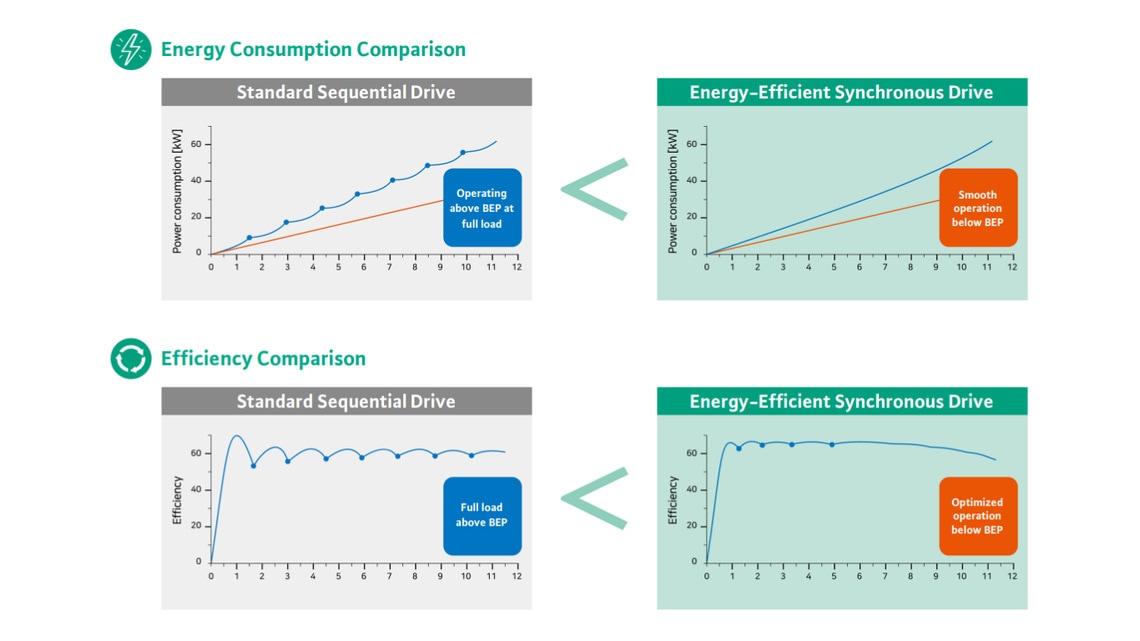

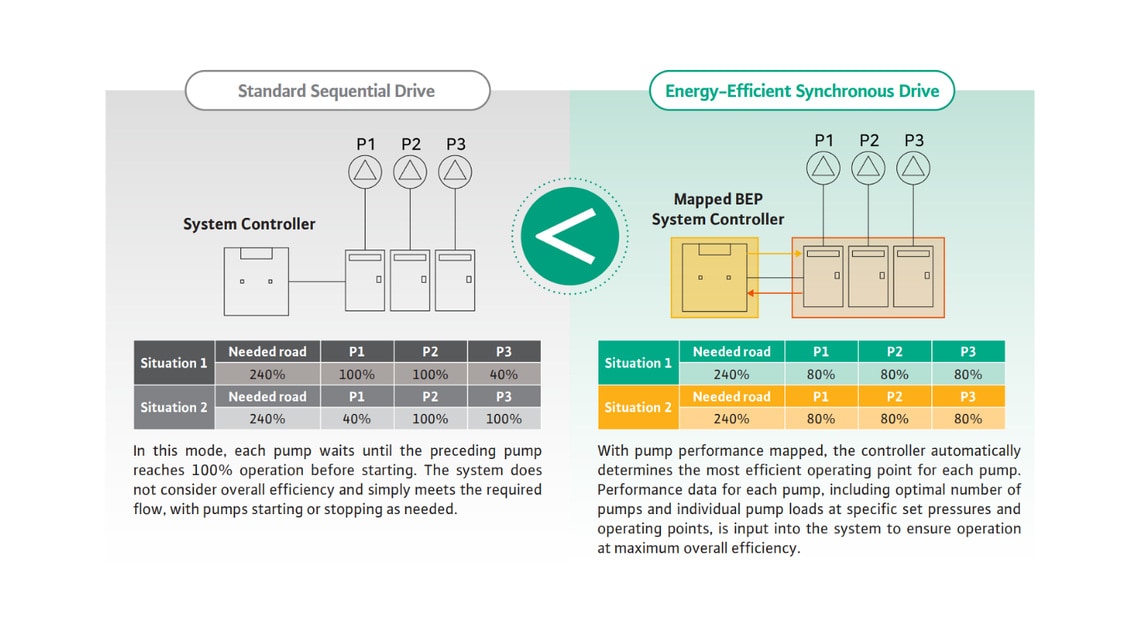

Energy-Efficiency Parallel Operation (Synchronous Drive)

Energy-efficiency parallel operation involves pre-entering pump data so that multiple inline pumps operate sequentially in synchronization at their Best Efficiency Point (BEP). By running pumps based on energy efficiency, this method helps achieve significant energy savings.

Optimal Pump Solution for Successful Liquid Cooling Systems

Microsoft opened its first data center in 2020 in Busan, South Korea, and has since built a second to support AI-powered cloud services across the Asia Pacific region.

Wilo provided Microsoft's Busan data center with an end-to-end solution, including a powerful and efficient HVAC solution for cooling, as well as a booster system for the center's water supply and drainage.

Powerful and High-Efficiency Pump Solutions for Data Center Infrastructure

In collaboration with DCX Liquid Cooling System, a global leader in liquid cooling systems, Wilo successfully supplied the Wilo-Atmos GIGA-B, a horizontal in-line pump mounted on the Cooling Distribution Unit (CDU).

With the recent advancement of AI technology, heat generation from high-performance servers has significantly increased, and liquid cooling solutions, which directly circulate a coolant, are gaining attention. The CDU is at the heart of this trend.

The Wilo-Atmos GIGA-B is a compact, horizontal-installation-compatible in-line pump suitable for CDUs, where various devices are densely packed and efficient space utilization is essential. Wilo supplied approximately 240 units of this pump for the project.

Wilo-SPS (Parallel Pumping System)

Applications

- Variable primary chiller loops

- Primary & secondary chiller loops

- Data centers/mixed-use commercial buildings/hospitals/airports

Key Features

- Supports parallel operation of up to 8 pumps

- Multiple operating modes

-

- Differential pressure control (dp-c/dp-v)

- Constant speed operation (N-const)

- Constant flow operation (Q-const)

- Delta temperature control (△t-const)

- Energy savings through energy-efficiency-based parallel operation

- Real-time remote monitoring via Wilo Smart Gateway

- Premium 7-inch touchscreen display

- BACnet and Modbus interfaces for building automation and bus communication

- Simplified design and commissioning

Technical Data

- Maximum Flow & Head: System-dependent

- Power Supply: 3~380V

- Power: System-dependent

- Compatible Fluids: Chilled/cooling water, heat exchange water, glycol mix (<40%)

Wilo-Stratos GIGA 2.0-I (High-Efficiency Electronically Controlled Inline Pump)

Applications

- Hot and cold water circulation in buildings and apartment complexes

- Hot water circulation

- Pressurized, condensate systems

- Cooling towers

Key Features

- Equipped with high-efficiency IE5 EC motor

- Multiple operating modes, including Dynamic Adapt Plus, for optimized efficiency

- Real-time remote monitoring via Wilo Smart Gateway

- Optimal operating mode settings tailored to the usage environment

- Premium 4.3-inch LED display with easy operation via Wilo Green Button

Technical Data

- Maximum Flow: 220m3/hr

- Maximum Head: 43m

- Operating Temperature: -20℃~+140℃

- Ambient Temperature: Max. +50℃

- Power Supply: 3~380 & 400 & 440V, 50/60Hz, 0.55~22kW

- Maximum Allowable Pressure: +140℃ at 13 bar / +120℃ at 16 bar

- Compatible Fluids: Chilled/cooling water, heat exchange water, glycol mix (<40%)

Wilo-Sensorless (High-Efficiency Sensorless Inline Pump)

Applications

- Heating, cooling, and condensing water systems

- Industrial, commercial liquid transfer units

Key Features

- Space-saving integrated inverter design

- Sensorless operation for precise, energy?efficient flow control

- High-efficiency IE3 motor (standard)

- Ultra-premium efficiency IE5 motor (optional)

- BACnet & Modbus for seamless building automation

- Robust enclosure: IP55 (standard), IP66 (optional)

Technical Data

- Maximum Flow: 1,700m3/hr

- Maximum Head: 75m

- Temperature Range: - 20°C~+140°C

- Power Supply: 3~380V, 60Hz

- Allowable Pressure: 16 bar (Optional: 25 bar)

Wilo-IL (High-Pressure Inline Pump)

Applications

- Hot and chilled water circulation in buildings

- Hot water circulation, domestic water circulation, cooling towers, and pressurization in residential complexes

- Condensate systems

Key Features

- Back-pull-out design for simple maintenance and motor/seal replacement (IL 250 Series)

- Inline casing with same-size suction and discharge ports

- Reinforced external ribs provide high safety even at high pressure (large models)

- 3D flow-optimized design reduces fluid resistance for maximum efficiency

Technical Data

- Maximum Flow: 1700m3/hr

- Maximum Head: 100m

- Temperature Range: -20°C~+140°C

- Power Supply: 0.4kW~5.5kW, 220/380V, 60Hz, 7.5kW~200kW, 380V(Y-△), 60Hz

-

Pressure Range According to Temperature:

- Up to +140°C at 13 bar

- Up to +120°C at 16 bar

Wilo-Atmos GIGA-I (High-Pressure Inline Pump)

Applications

- Hot and chilled water circulation in buildings

- Hot water circulation, domestic water circulation, cooling towers, and pressurization in residential complexes

- Condensate systems

Key Features

- IEC-standard motor for wide compatibility

- Rigid split coupling connection

- Standard mechanical seal(optional cartridge seal for 4-pole ≥37 kW)

- Inline casing with same-size suction and discharge ports

- Reinforced ribs provide high safety even at high pressures (large models)

- 3D flow-optimized design reduces fluid resistance for maximum efficiency

Technical Data

- Maximum Flow: 700m3/hr

- Maximum Head: 140m

- Temperature Range: -20°C~+140°C

- Power Supply: 0.4kW~5.5kW, 220/380V, 60Hz, 7.5kW~200kW, 380V(Y-△), 60Hz

-

Pressure Range According to Temperature:

- Up to +140°C at 13 bar

- Up to +120°C at 16 bar

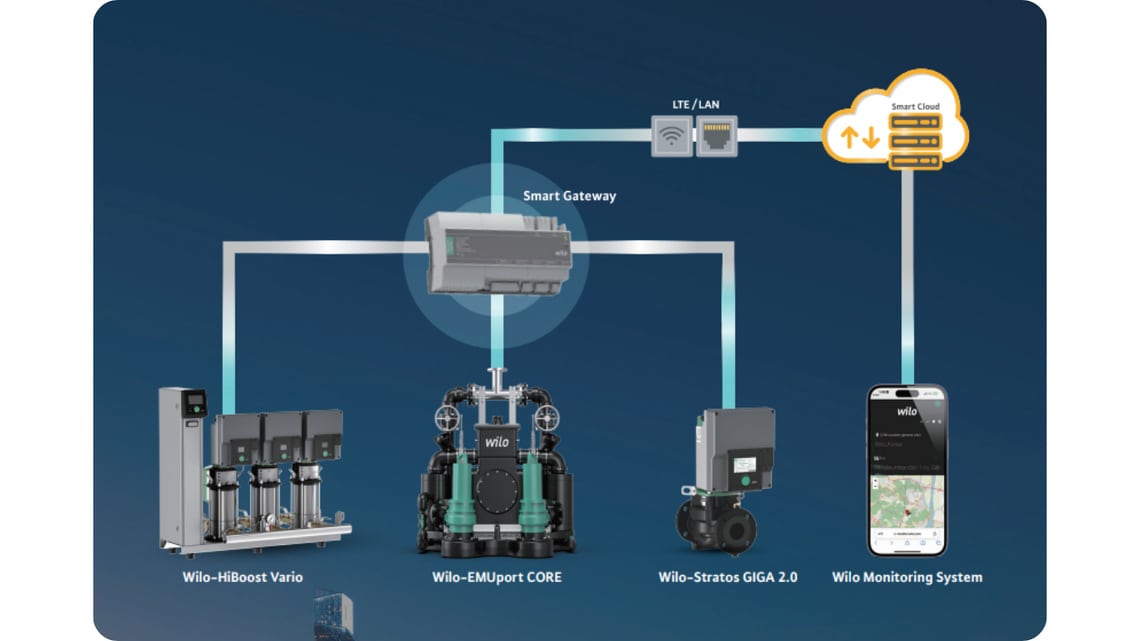

Wilo-Smart Gateway & Monitoring System (Real-Time Remote Monitoring System)

Applications

- Compatible with Wilo booster systems, inline pumps, and drainage pump panels

Key Features

- Real-time remote monitoring of pumps and pump systems

- Cloud-based Wilo Smart Gateway for seamless connectivity

- Maximum operational safety guaranteed

- Sends alerts to users and headquarters in case of abnormal operation

- Rapid response prevents incidents such as water outages

Wilo-Stratos GIGA-B (High-Efficiency Electronically Controlled Monoblock Pump)

Applications

- Hot and cold water circulation in buildings and apartment complexes

- Hot water circulation

- Pressurized, condensate systems

- Cooling towers

Key Features

- Equipped with high-efficiency IE5 EC motor

- Multiple operating modes, including Dynamic Adapt Plus, for optimized efficiency

- Real-time remote monitoring through Wilo Smart Gateway

- Optimal operating mode settings tailored to the usage environment

- Premium 4.3-inch LED display with easy operation via Wilo Green Button

Technical Data

- Maximum Flow: 520m3/hr

- Maximum Head: 82m

- Operating Temperature: -20℃~+140℃

- Ambient Temperature: Max. +50℃

- Power Supply: 3~380 & 400 & 440V, 50/60Hz, 0.75~22W

- Maximum Allowable Pressure: +140℃ at 13 bar / +120℃ at 16 bar

- Compatible Fluids: Chilled/cooling water, heat exchange water, glycol mix (<40%)

Wilo-MEDANA CH1-L (Stainless Steel Horizontal Multistage Pump)

Applications

- For mechanical equipment, including chillers

- Cooling water circulation

- General-purpose and agricultural water supply

- Irrigation and potable water distribution

Key Features

- Corrosion-resistant stainless steel construction

- Compact design allows flexible installation and efficient space use

- Extensive product lineup to suit various needs

- Quick-connect screw-type interface

- Durable electrophoretic coating

- Enhanced motor insulation for greater durability and reliability

- Sturdy pump base

Technical Data

- Maximum Flow: 30m³/h

- Maximum Head: 99m

- Fluid Temperature: -15°C to +110°C

- Ambient Temperature: -15°C to +40°C

- Power Supply: 1ph 220V, 60Hz & 3ph 220V/380V, 60Hz

- Maximum Operating Pressure: 10bar

- Compatible Fluids: Low-viscosity fluids such as chilled/hot water or condensate, without fibers or abrasive materials

Wilo Service Solution

Wilo Maintenance and Repair Solutions

Wilo's maintenance and repair solutions are based on Wilo's extensive infrastructure and the largest service network in the Korean pump industry. These services are tailored to on-site conditions and customer needs, ensuring safe and convenient pump management and providing cost-saving benefits.

Service Offerings

*Services may vary depending on the contract

| General inspection & checklist | Detailed inspection & Inspection Report |

Dedicated service infrastructure & emergency contact network |

| On-site emergency service | Emergency repair |

Supply of key spare parts & direct pump supply |

|

Annual unit-price contract (labor, spare parts & products) |

Scheduled overhaul (consumables) | Wilo monitoring system setup |

Maintenance and Repair Service Site

Case Studies

Wilo Digital Solution

Wilo Smart Gateway & Monitoring System

The Wilo Smart Gateway and Monitoring System is a digital solution that enables real-time remote monitoring. The operating status of the pump is securely stored in the Wilo Smart Cloud via the Smart Gateway. When a pump malfunction is detected, an alarm is sent to both the head office service team and the customer.

This system allows you to check the pump's status in real-time without having to be physically present in the machine room. When necessary, preventive maintenance is performed through on-site dispatches to prevent problems before they occur. Additionally, regular inspection reports provide a complete overview of the pump's operational status.

This solution helps you efficiently manage pumps and pumping systems and prevent accidents, leading to reduced life cycle costs for your pumps.

Wilo Data Center Solution Brochure