Wilo-Sub TWU 3 HS

Your advantages

- Constant, adjustable pressure thanks to external frequency converter with integrated control (TWU 3 HS-ECP)

- Easy installation with no additional sensors provided by the customer for pressure control (TWU 3 HS-ECP)

- High output thanks to integrated frequency converters with fixed motor speed of 8,400 rpm (TWU 3 HS-I)

- Reduction of well bore expansion and installation costs due to narrower diameter and installation volume

- Comprehensive monitoring and protection functions for absolute operational reliability

Design

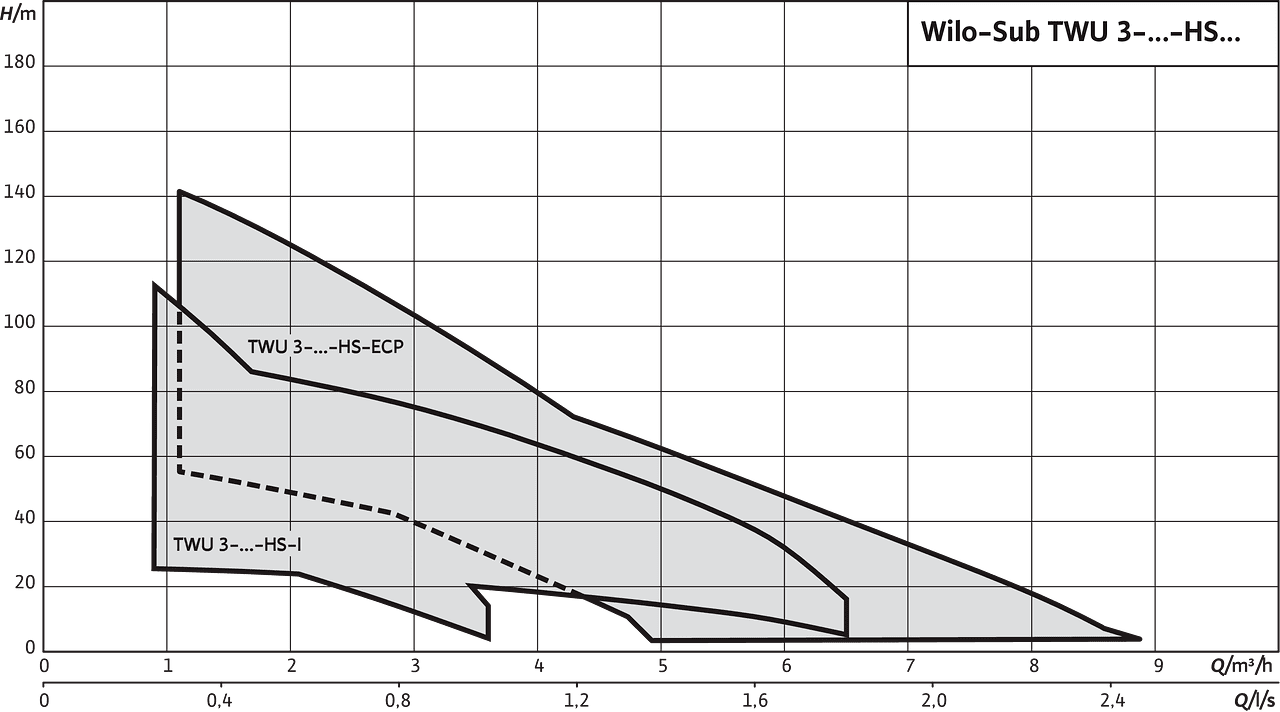

Multistage, frequency controlled 3" submersible pump in jacketed construction for vertical or horizontal installation

Application

For pumping rainwater and industrial water from boreholes and wells for sprinkling, irrigation and water supply.

Equipment/function

TWU 3-...-HS-I

- Integrated non-return valve

- Integrated frequency converter with the following functions:

- Soft starter

- Undervoltage, overvoltage and short-circuit protection

- Thermal overload protection of the motor and frequency converter

- Dry-running protection

TWU 3-...-HS-ECP-B

- Integrated non-return valve

- External frequency converter with the following functions:

- Soft starter

- Undervoltage, overvoltage and short-circuit protection

- Thermal overload protection of the motor and frequency converter

- Constant pressure control

- Leakage detection for avoiding excessive switching cycles (pulse)

- Dry-running protection with automatic reset

- Change of direction of rotation

- Settings for max. current and nominal pressure

- Pressure indicator on the display

- Settings, operating statuses and error messages are shown by LEDs and on the display

Constant pressure control function

The frequency converter controls the speed of the pump based on the nominal pressure. As a result, the submersible pump always delivers a constant pressure.

Typekey

Example: | Wilo-Sub TWU 3-0305-HS-E-CP-B |

TWU | Series |

3 | Diameter of the hydraulic unit in inches ["] |

03 | Rated volume flow [m3/h] |

05 | Number of hydraulic stages |

HS | High-speed version |

E | Frequency converter version

|

CP | Constant pressure control |

B | Version with permanent magnet motor |

Technical data

Submersible pump:

- Supply voltage: HS-E…: 1~230 V, 50/60 Hz (connection via the frequency converter to the AC mains supply) HS-I...: 1~230 V, 50/60 Hz (direct connection to the AC mains supply)

- Submerged operating mode: S1

- Fluid temperature: 3 – 35 °C

- Minimum flow rate at motor: 0.08 m/s

- Max. sand content: 50 g/m3

- Max. number of starts: 30/h

- Max. immersion depth: 150 m

- Protection class: IP58

- Discharge port: Rp 1/Rp 1¼

Frequency converter for version “HS-E…”:

- Mains connection: 1~230 V, 50/60 Hz

- Output: 3~230 V/max. 140 Hz/max. 2.2 kW

- Fluid temperature: 3 – 50 °C

- Max. pressure: 8 bar

- Protection class: IPX5

- Connection: G 1¼

Materials

- Hydraulics housing: 1.4301

- Impellers: Polycarbonate

- Hydraulic shaft: 1.4104

- Motor housing: 1.4301

- Motor shaft: 1.4305

Construction

Submersible pump for vertical or horizontal installation.

Hydraulics

Multistage submersible pump with radial impellers in sectional construction and integrated non-return valve. Discharge port with threaded flange and female thread. All parts that come in contact with the fluid are made of corrosion-free materials.

Motor (...HS-E...-B)

Corrosion-free permanent magnet motor for connection to the supplied frequency converter. Oil-filled motor with self-lubricating bearings, designed for high speeds up to 8400 rpm.

The frequency converter is installed directly in the discharge pipeline outside the fluid (flood-proof). The motor is cooled by the pumped fluid.

Motor (...HS-I)

Corrosion-free asynchronous motor with integrated frequency converter for direct connection to the mains supply. Rewindable, oil-filled motor with self-lubricating bearings, designed for high speeds from 8400 rpm.

Cooling

- The motor is cooled by the pumped fluid. Always operate the pump in a submerged state.

- Vertical installation is possible with or without cooling jacket.

- Horizontal installation must be performed in conjunction with a cooling jacket.

Scope of delivery

- Hydraulics + motor completely assembled

- Frequency converter (...HS-ECP)

- 1.75 m connection cable

- Installation and operating instructions

Accessories

- Cooling shroud

- Diaphragm expansion tank

- Gate valve

- Float switch

- Pressure switch

- Electrode

- Switchgear

- Alarm switchgear

- Casting resin kit

- Connection cable