12.07.2018

Smart sewage pump station with Nexos Intelligence

Water shortage is one of the megatrends of our times. Coincidentally, sewage treatment faces an increasing solids content and ever greater energy-efficiency requirements. Also, challenges such as wet-wipes impact the operational reliability. Reliable and digitally networked high-efficiency solutions like the new Wilo-Rexa SOLID-Q with Nexos Intelligence are needed to create future-proof infrastructures and processes. With this intelligent system solution for smart sewage pump stations, Wilo offers a cutting-edge solution to the requirements of our times.

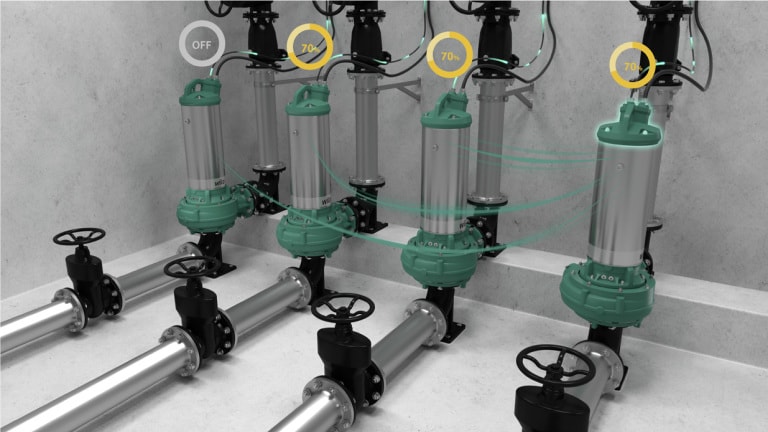

Wilo’s vision for a smart sewage pump station is a solution that offers outstanding operational reliability, energy efficiency and connectivity. These modules are the latest developments in motor and hydraulics technology and offer integrated control intelligence: “We take Nexos Intelligence to mean systems that are capable of responding intelligently to local changes in conditions without requiring the operator’s intervention”, explains Matthias Pantze, Product Manager at Wilo. A good example is the redundant master/slave control in the Wilo-Rexa SOLID Q: in a system consisting of up to four pumps, one is set as the “master” and then controls and regulates the operation of the entire system. Every single pump still has the same electronics and is therefore ready to take over control of the system. The operational advantages: if the master, for example, is switched off for maintenance purposes, one of the other three “slave” pumps are available to automatically assume control of the system. Other features of the Nexos Intelligence are the intelligent energy-efficiency optimisation function and the highly sophisticated clogging detection function. The former autonomously sets the most energy-efficient pump speed using a regular measuring cycle based on the pump’s specific system conditions at that time. This significantly reduces unnecessary energy consumption caused by pipe friction losses. The clogging detection function is customised to the specific hydraulics type to deliver the best possible result: signs for an impending impeller blockage are monitored by several algorithms that can initiate the necessary pump cleaning cycles automatically. For the Rexa SOLID-Q, the Nexos Intelligence, including the PLC control function, is uploaded to the new Wilo-Digital Data Interface (DDI) installed in the motor head. This means that the entire control intelligence is already integrated into the pump, which makes the frequency converter replaceable without downtime while an additional external control unit is no longer necessary.

A SMART SEWAGE PUMP STATION, AN INTELLIGENT SYSTEM SOLUTION

The Wilo-Rexa SOLID-Q

sewage pump was designed for conveying untreated sewage in medium-sized pumping stations, both in wet well and dry well installation. The DDI integrated into the motor comprises the IP-based, digital Ethernet interface as well as a data logger, a digital rating plate and an integrated vibration monitor: “The integrated Ethernet interface makes it is easier than ever before to connect the pump to the system using just one plug, despite the extensive array of sensors”, the Product Manager explains. Using the integrated webserver, the Rexa SOLID-Q is controlled and monitored via the network interface or directly via the externally connected touch panel. The system interface is conveniently accessible via a web browser and supports all operating systems. The user manual and information on the rating plate, motor and hydraulics data are also available online. The use of standardised network protocols allows for the seamless integration into cloud-based remote data transmission technology. The integrated data logger saves all operational data, such as the winding and bearing temperatures, data from external sensors, frequency converter performance data or the fill level of the chamber. By exporting the data via a webserver, the operator can analyse the information in more detail or troubleshoot possible causes of a system malfunctioning. The IE5 high efficiency motor with permanent magnet technology achieves the highest electrical efficiency across a much broader load range than asynchronous technology, resulting in optimised energy costs even in partial load operation. The new SOLID-Q hydraulics are similar to the proven SOLID-G impellers, but their two blades give it a higher efficiency, a lower vibration tendency and make it particularly suitable for controlling at the frequency converter. Thanks to the integrated intelligent functions, it offers a variable duty point configuration and an uncompromised operational reliability.