Wilo-CronoBloc-BL-E

Your advantages

- Energy savings due to integrated electronic power adjustment

- Optional interfaces for bus communication using plug-in IF-Modules

- Simple operation due to tried-and-tested Green Button Technology and display

- Integrated full motor protection (PTC thermistor sensor) with trip electronics

- Meets user requirements thanks to performance and main dimensions in accordance with EN 733 (for end-suction pumps)

Recommended services

Eco-friendly features

- Use of IE4 motor technology and hydraulics with an MEI ≥ 0.4 saves energy

- Sustainable and carbon-neutral production and processes in our European factories

Design type

Electronically controlled glanded single pump in monobloc design with flange connection and automatic power adjustment.

Application

The pumping of heating water (in accordance with VDI 2035), chilled water and water-glycol mixtures without abrasive substances in heating, chilled water and cooling systems.

Equipment/function

Operating modes

- Δp-c for constant differential pressure

- Δp-v for variable differential pressure

- PID-Control

- Constant speed (n=constant)

Manual operation level

- Green button and display

Manual functions

- Differential pressure setpoint setting

- Setting the speed (manual control mode)

- Setting the operating mode

- Setting the pump ON/OFF

- Configuration of all operating parameters

- Fault acknowledgement

External control functions

- 1x “Overriding Off” control input

- 1x “External pump cycling” control input (effective only in twin-head pump operation)

- 1x Analogue input 0–10 V, 2–10 V, 0–20 mA, 4–20 mA for constant speed (DDC) and remote setpoint adjustment

- 1x Analogue input 0–10 V, 2–10 V, 0–20 mA, 4–20 mA for actual value signal from pressure sensor

Signal and display functions

- Collective fault signal SSM

- Collective run signal SBM

Data exchange

- Infrared interface for wireless data exchange with IR-Stick

- Plug-in position for Wilo IF-Modules (Modbus, BACnet, CAN, PLR, LON) for connection to building automation

- Interface to dual-pump communication

Safety functions

- Full motor protection with integrated trip electronics

- Access disable

Dual-pump management (2 x single pump; Y-piece application only)

- Main/standby operation (automatic fault-actuated switchover)

- Pump cycling main/standby operation after 24 hours

- Parallel operation

- Parallel operation (efficiency-optimised peak load activation and deactivation)

Typekey

Example | BL-E 80/145-11/2-xx |

BL-E | Monobloc pump with electronic control |

80 | Nominal diameter DN of the pipe connection (discharge port) |

145 | Nominal impeller diameter in mm |

11 | Rated power of motor P2 in kW |

2 | Number of poles |

-xx | Version: E.g. R1 - version without differential pressure sensor |

Technical data

- Permissible temperature range of -20 °C to +140 °C

- Minimum efficiency index (MEI) ≥ 0.4

- Mechanical seal for pumping water up to Tmax = +140 °C. Up to T ≤ +40 °C, a glycol admixture of 20 % to 40 % by volume is permissible. An alternative mechanical seal must be provided for water-glycol mixtures with a glycol content of > 40% to max. 50% by volume and a fluid temperature of > +40 °C to max. +120 °C or other fluids that differ from water. When using water-glycol mixtures, the use of an S1 variant with a corresponding mechanical seal is generally recommended.

- Mains connection

- 3~440 V -5% +10%, 50/60 Hz

- 3~400 V ±10%, 50/60 Hz

- 3~380 V -5% +10%, 50/60 Hz

- Compliance with electromagnetic compatibility without additional measures:

- Interference emission for residential environment according to EN 61800-3:2018

- Interference immunity for industrial environments according to EN 61800-3:2018

- IP55 rating

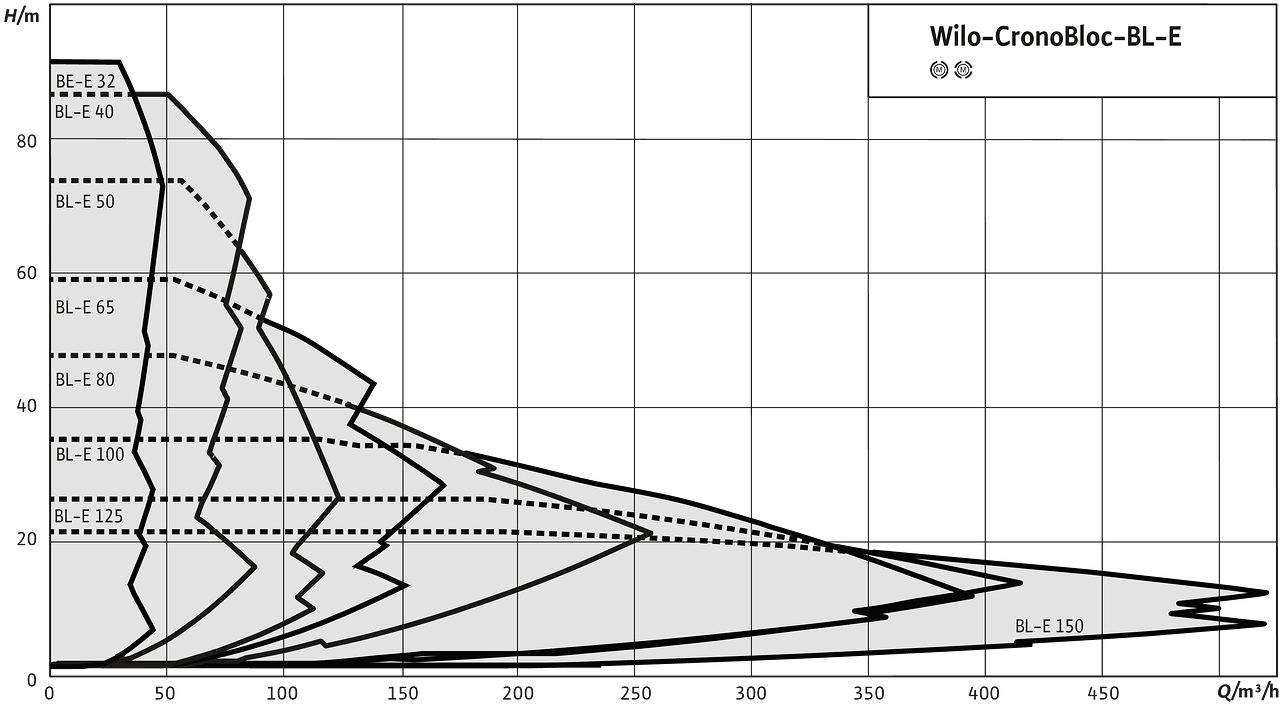

- Nominal diameter DN 32 to DN 150

- Max. operating pressure 16 bar up to +120 °C, 13 bar up to +140 °C

Materials

- Pump housing and lantern: EN-GJL-250

- Impeller

- Standard version: EN-GJL-200

- Special version: Bronze CuSn 10

- Special version: Stainless steel 1.4408

- Shaft: 1.4122

- Mechanical seal: AQEGG; other mechanical seals on request

Construction

Single-stage low-pressure centrifugal pump in monobloc design, with axial suction port and radially arranged discharge port with

- Mechanical seal

- Flange connection with pressure measuring connection R 1/8

- Lantern

- Coupling

- Drive with integrated electronic speed control

Scope of delivery

- Pump

- Installation and operating instructions

Options

- Variant …-R1 without differential pressure sensor

- ...-L1 variant with bronze impeller (at additional charge)

- …-L4 variant with stainless steel impeller (at additional charge)

Accessories

- Supporting blocks for installation on a base

- IR-Stick

- IF module PLR for connecting to PLR/interface converter

- IF module LON for connection to the LONWORKS network

- IF module BACnet

- IF module Modbus

- IF module CAN

- Control system VR-HVAC

- Control system CCe-HVAC

- Control system SCe-HVAC

- Differential pressure sensor (DDG)