Wilo-Rexa FIT

Your advantages

- Ready-to-plug and immediately ready to go (A and P version)

- Attached float switch (A-model) enables easy operation

- Safe vortex hydraulics with large, free ball passage pump in non-clog design during operation

- Sealing chamber with optional external monitoring

- Lightweight

Recommended services

Eco-friendly features

- Efficient design with special components for the lowest possible weight load

- Optimised hydraulics for greater operational reliability and fewer unscheduled maintenance visits

Design type

Submersible pump for stationary and portable wet installation in intermittent operation.

Liquid

For pumping in commercial areas of:

- Sewage containing faeces

- Wastewater (with small amounts of sand and gravel)

Sewage pumping according to 12050

The pumps meet the requirements of EN 12050-1.

Equipment/function

- Thermal motor monitoring with bimetallic sensor

- Single-phase AC motor with self-switching thermal motor monitoring

- Single-phase AC motor with integrated condenser

- Different versions:

- Version “P”: with plug

- Version “A”: with float switch and plug

- Version “O”: bare cable ends

Typekey

Example: | Wilo-Rexa FIT-V06-212A/21T011-540/A |

Rexa | Submersible sewage pump |

FIT | Series |

V | Impeller shape: Vortex impeller |

06 | Nominal diameter of discharge port, e.g. DN 65 |

212 | Hydraulics type |

A | Hydraulics material version: Standard version |

2 | Number of poles |

1 | IE-efficiency class (derived from IEC 60034-30) |

T | Mains connection version:

|

011 | Value/10 = Rated power P in kW |

- | Not Ex-rated |

5 | Mains frequency: 5 = 50 Hz/6 = 60 Hz |

40 | Key for rated voltage |

A | Additional electrical equipment:

|

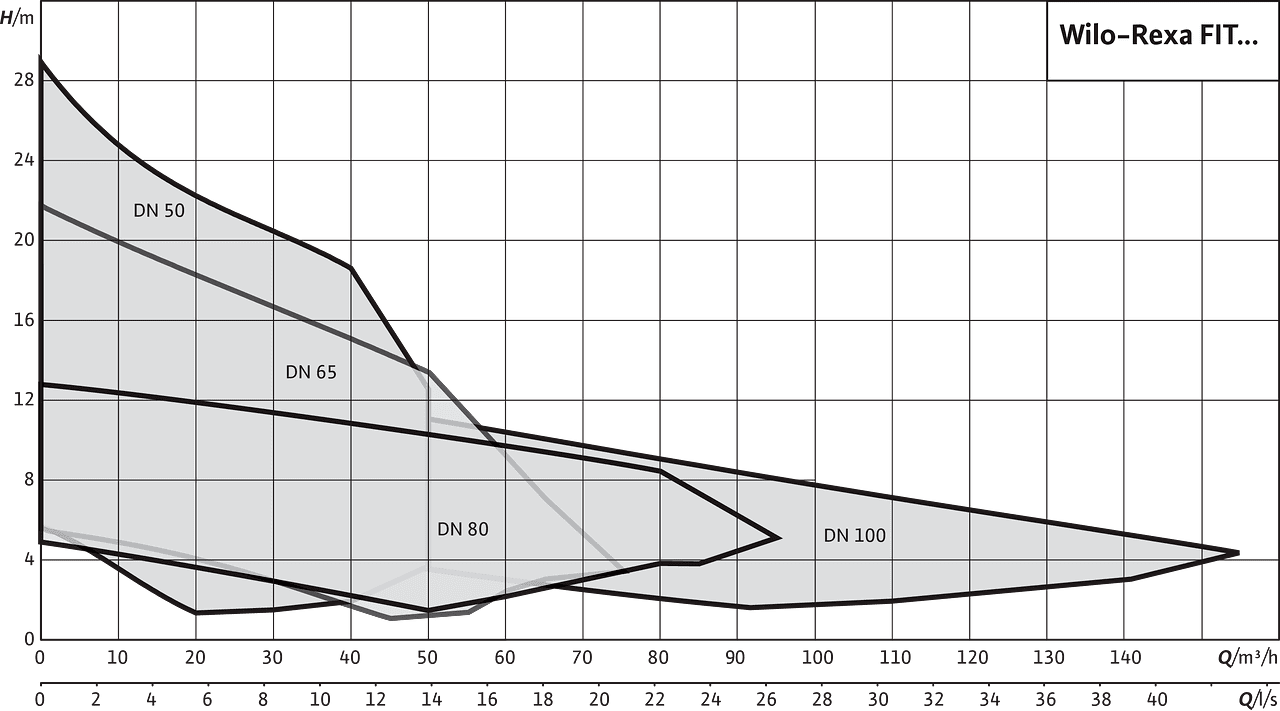

Technical data

- Mains connection: 1~230 V, 50 Hz or 3~400 V, 50 Hz

- Submerged operating mode: S1

- Non-immersed operating mode: S2-15 min; S3 10%

- IP rating: IP68

- Insulation class: F

- Fluid temperature: 3 … 40 °C (37 … 104 °F)

- Fluid temperature, max. 60 °C (140 °F) for 3 min

Materials

- Hydraulics housing: EN-GJL-250 (ASTM A48 Class 35/40B)

- Impeller: EN-GJL-250 (ASTM A48 Class 35/40B)

- Motor housing: 1.4301 (AISI 304)

- Shaft: 1.4021 (AISI 420)

- Seal on the motor side: C/MgSiO

- Seal on the fluid side: SiC/SiC

- Seal, static: NBR (nitrile)

Construction

Rexa FIT-V ... /M ... /P

Submersible pump with vortex impeller and horizontal discharge port with flange connection. Hydraulics housing and impeller made of grey cast iron. Surface-cooled 1~ motor with integrated operating capacitor and self-switching thermal motor monitoring. Oil-filled sealing chamber with two mechanical seals. Stainless steel motor housing. Detachable connection cable with fitted plug (CEE7/7). The pump may be used in Zone 2 hazardous areas.

Rexa FIT-V ... /M ... /A

Submersible pump with vortex impeller and horizontal discharge port with flange connection. Hydraulics housing and impeller made of grey cast iron. Surface-cooled 1~ motor with integrated operating capacitor and self-switching thermal motor monitoring. Oil-filled sealing chamber with two mechanical seals. Stainless steel motor housing. Detachable connection cable with float switch and fitted plug (CEE7/7). The pump must not be used in hazardous areas.

Rexa FIT-V ... /T ... /A

Submersible pump with vortex impeller and horizontal discharge port with flange connection. Hydraulics housing and impeller made of grey cast iron. Surface-cooled 3~ motor with thermal motor monitoring. Oil-filled sealing chamber with two mechanical seals. Stainless steel motor housing. Detachable connection cable with CEE plug (16A, 3P+N+PE, 6h). Float switch and thermal motor monitoring connected to the CEE plug. The pump must not be used in hazardous areas.

Rexa FIT-V ... /T ... /O

Submersible pump with vortex impeller and horizontal discharge port with flange connection. Hydraulics housing and impeller made of grey cast iron. Surface-cooled 3~ motor with thermal motor monitoring. Oil-filled sealing chamber with two mechanical seals. Stainless steel motor housing. Detachable connection cable with bare cable ends. The pump may be used in Zone 2 hazardous areas.

Scope of delivery

- Pump

- Installation and operating instructions

Accessories

- Connection cable with fixed cable lengths:

- 1~ motor: up to max. 30 m (98 ft).

- 3~ motor: up to max. 50 m (164 ft).

- External pencil electrode for monitoring the sealing chamber

- Suspension unit for wet installation

- Pump support foot for portable installation

- Level control devices

- Fixation sets with bonded anchor

- Fixation accessories and chains

- Switchgear, relays and plugs