Application and selection options

Targeted data mining in Building Services.

Application Configurator

Use our configurator to find out which control type is right for your application.

read moreDiscover Wilo-World

Get to know our application areas in our interactive Wilo-World.

Discover the Wilo-World nowExample: Constant differential temperature

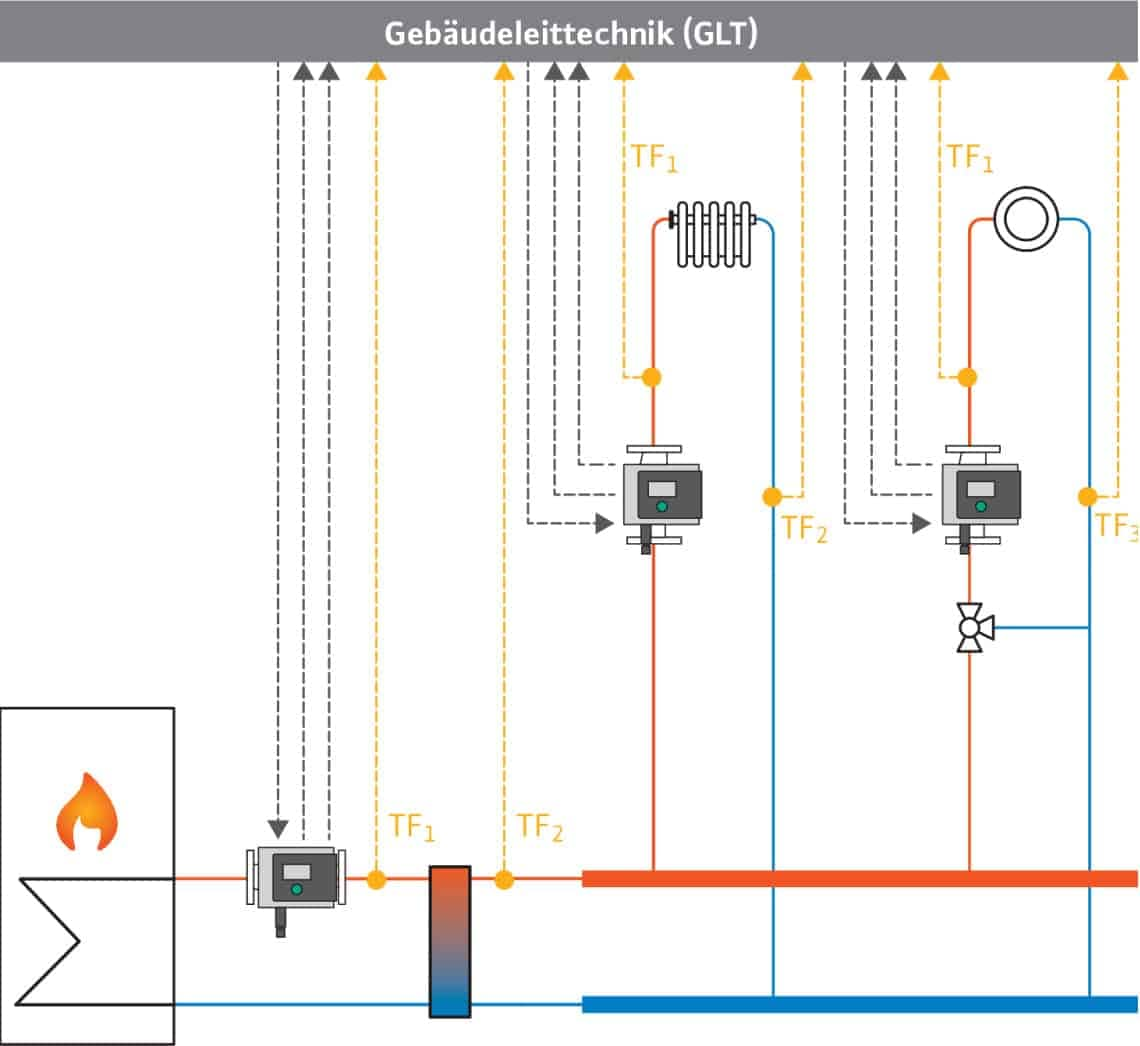

Disadvantages of conventional wiring/control

- Analogue data items

- Temperature controlled centrally in the building management system

-

Required accessories per pump:

2 x temperature sensor

System information:

- Pump on/off, feedback missing

- Collective fault signal

- Feed temperature

- Return temperature

- Hours of operation, derived

Disadvantages of conventional cabling

- Lots of cabling work and additional costs

- Analogue control parameters have to be entered separately (e.g. temperature)

- Star-connected wiring of fault and run signals

- High degree of wear due to frequent activation and deactivation of the pumps

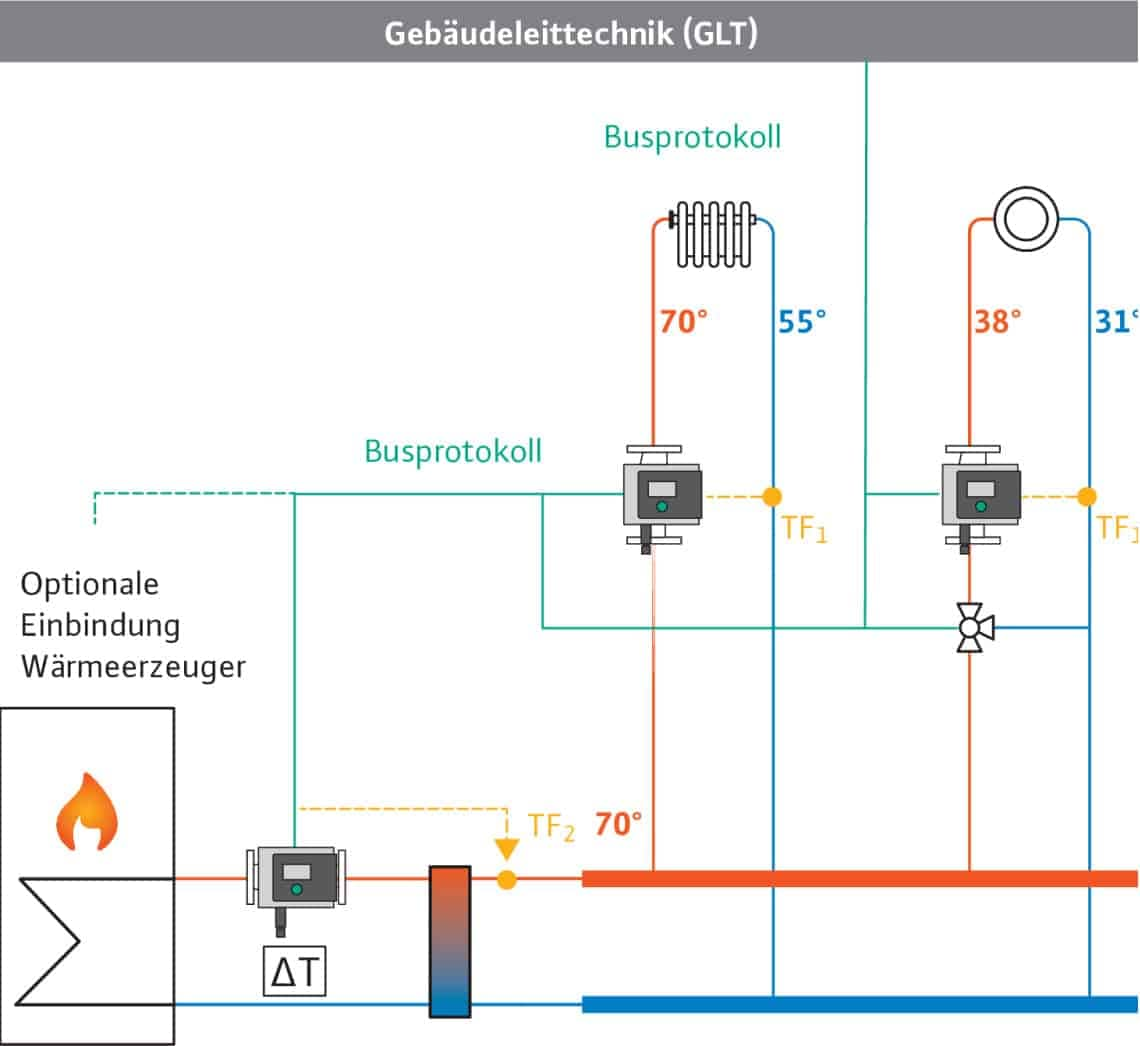

Advantages of bus-compatible cabling/control

- Digital data items

- Temperature controlled decentrally in the pump

-

Required accessories per pump:

1 x temperature sensor PT1000-AA, 1 x Wilo CIF module

System information

- Volume flow

- Delivery head

- Operating hours

- Feed temperature

- Return temperature

- Digital inputs

- Operating status of the system

- Heating/cooling quantity

- Fault and run signals including index

- …

Advantages of bus-capable cabling:

- Considerably less cabling work and costs

- Low fire load because of simple cabling

- Decentral control within the pumps

- High energy savings due to needs-based control of the pumps

- Digital processing of data items and queries for virtual data item (e.g. heating/cooling quantity)

- One language between the building management system and all pumps

- Simple commissioning, modular and decentral, via the pump display