Wilo-Nexos NET-Intelligence

Smart, reliable, cost-efficient.

Application-specific challenges:

Increasing solids and fat content

The economical use of precious water resources almost goes without saying these days, although it also increases the share of increasingly fatty solids in sewage to the same extent. The pumping of sewage is proving to be increasingly more complicated because of this.

Minimum flow rates in collector pipes

- Drainage pipes must be correctly sized to allow the sewage to flow and prevent clogging.

- Pipes which are too small cannot receive sewage. In pipes which are too large, there is the risk of faeces and solids remaining and collecting, which also leads to clogging.

- If too few pumps are working at the same time, sewage quantities vary depending on the time of day and the time of year. Consequently, pumping stations are not continuously in operation, which means that pressure drainage systems transport too little sewage about 70 % of the time. The irregular volume flow not only increases energy costs, it also causes deposits and even clogging in the pipes.

Deposits and clogging

- Deposits reduce the outflow cross-section and, in the worst cases, lead to clogging. Many deposits would be avoidable, as they occur partly because pipe networks with numerous small, autonomous pumping stations cannot guarantee the minimum and maximum flow rates of 0.7 m/s and 2.3 m/s respectively in the collector pipelines.

- The irregular volume flow increases energy costs and causes deposits and even clogging in the pipes which the operator, often municipal authorities, must remedy at considerable effort and cost – from once per year up to every three weeks.

High operating costs

Flow rates which are too low lead to deposits and clogging which must be dealt with at great cost. Flow rates which are too high lead to higher friction loss and thus higher energy costs, and, in extreme circumstances, even pipes breaking and pumps becoming damaged.

Lack of control and transparency

Drainage systems are built underground and are mostly not connected so it is not possible to access the current system status – remote control is not possible. A system overview can only be established “live” on location, which means no transparency and overview of threats such as potential clogging can be provided.

Wilo-Nexos NET-Intelligence –

The pressure drainage system with Nexos Intelligence

Solutions that deliver more, reliably.

Clogging-free, energy-efficient operation

Optimised flow rates in the collector pipelines ensure that pressure drainage systems are energy efficient and run without clogging.

Reduced operating costs

Operating costs are reduced by early fault detection and targeted troubleshooting.

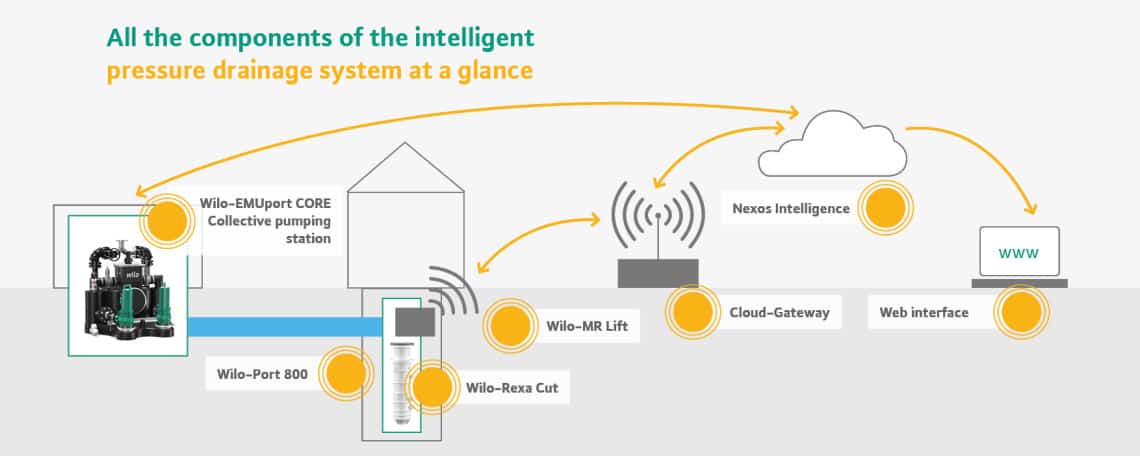

- The full system consists of the Wilo-Port 800 pump chamber, the Wilo-Rexa CUT submersible sewage pump with macerator, the Wilo-MR Lift switchgear with radio antenna, a gateway and a new cloud-based control surface.

- This enables comprehensive networking, monitoring and control of a pressure drainage system.

- The individual pumping stations are digitally networked with one another and with a central control software system.

- This intelligent solution ensures compliance with optimal flow rates in the collector pipelines and collective pumping stations, while also minimising the risk of deposits and clogging. The minimum flow rates are achieved.

- The pumps are economical to use as their duty points are optimised to ensure reliable operation with low rates of wear.

- All status information is collected at a central server, which means that any error messages are recognised early and sent via text message and e-mail. This first of all allows the operator to take specific action and prevent bigger damage to the system.

- On top of this, Nexos Intelligence provides the option of controlling either individual pumping stations or all pumping stations together. Particularly during maintenance work on the collective pumping station, this can result in temporary deactivation of the entire pressure drainage system and avoid backflow.

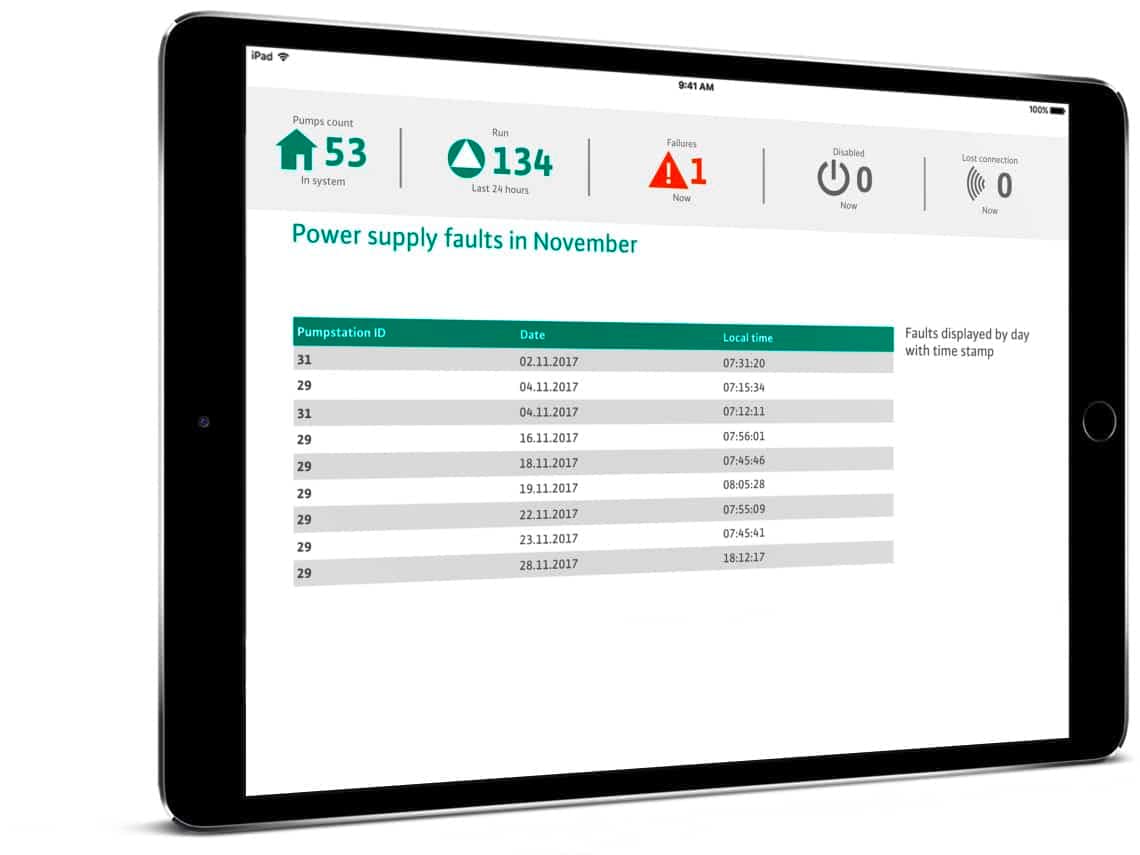

- Automated status reports - comprehensive transparency for more increased operational reliability and safety

- Highly accurate fault messages based on a pumping station

- Motor protection for non-return valve breakdown or blocked pressure pipe

- Identification of fault messages specifically for a pumping station

- The operating status of each pumping station is visible at any time and anywhere on the cloud interface.

- Extensive analysis functions with the key system status information: from detailed daily process curves to complete annual assessments.

- Smart networking through the pressure drainage system with Nexos Intelligence offers three key benefits: high operational reliability, comprehensive control over the system and energy savings.

Nexos Intelligence

-

Wilo-EMUport CORE

-

-

Port 800

Learn more about the software and its control options

For the first time, absolute transparency is on offer: The operating status of the entire pressure drainage system can be viewed at any time at a glance. Daily curves and comparison of the actual values with the monthly and annual average. Deviations are immediately apparent.

Wilo-Nexos NET-Intelligence reduces pumps’ energy consumption by up to 30 % by distributing peak inflows where the system is under heavy load, such as on public holidays. At times when the system is not subject to such heavy loading, the software ensures that the minimum flow rates in the collector pipes are also achieved to avoid the risk of clogging due to the build-up of deposits.

Once an error occurs, the error patterns in the system can help identify the source and reason for the problem. Erroneous areas are marked in a visual overview and reduce response times for maintenance staff.

Daily, monthly or yearly statistical overviews can be accessed via the system. Irregularities and potential areas for improvement in the pressure drainage network are easily identified. Specific detailed analysis takes place at the pump ID level. The software enables targeted introduction of countermeasures.

The software can be integrated smoothly into existing or new systems to improve efficiency and reliability.

Smart networking for the community of Tczów in Poland

0 faults - 100 % reliable

The situation in the community of Tczów

The pipes in the Polish community of Tczów were particularly susceptible to the build-up of deposits or even clogging due to irregular flow rates, which the operator had to rectify for the community at high cost.

The Wilo solution

Ten years ago, Tczów became the first community to test Wilo-Nexos NET-Intelligence. 185 of the 750 local pumping stations were digitally connected. The use of this control system facilitates a distribution of the peak inflows on days when the system is under heavy load. At times when the system is not subject to such heavy loading, the pressure drainage system with Nexos Intelligence ensures that the minimum flow rate of 0.7 m/s is also achieved in the collector pipes to avoid the risk of clogging due to the build-up of deposits.

Our solution in numbers

4,500 population

0 breakdowns

750 pumping stations

72 km² area

30 % energy saving

185 networked pumping stations

Smart, reliable and economically efficient

- Faults that occur can be detected automatically using the fault patterns and thus the reason for the problem can be identified.

- This reduces the response time of the community’s maintenance personnel and, as a result, lowers maintenance costs.

- Smart networking provides energy savings of up to 30 % and allows access to daily, monthly or annual statistics for the whole system.

FAQ

How does Wilo-Nexos NET-Intelligence work?

In this case, a modern cloud solution is used. The signals are sent from house pumping stations to a gateway via radio signals in a so-called mesh system. This communication method allows the pumping stations to send each other signals so that the system also manages without available infrastructure. The gateway communicates via mobile data or LAN with the cloud server which the software runs on centrally.

What are the advantages of the system?

The system optimises flow rate in pressure pipes above all. On the one hand, we achieve 100 % clogging-free status by complying with the relevant flow rates in pressure pipes during phases of minimum inflow of sewage into the system. On the other hand, energy is saved through intelligent activation of pumping stations in the period where the amount of sewage coming into the system is larger. Nexos Intelligence also has many functions enabling optimisation of the system and prediction or even prevention of alarm conditions. For instance, this allows the system to predict the clogging of pipes at an early stage. The software also recognises highly atypical situations such as the breakdown of the non-return valve or the unwanted influx of rainwater.

Which functionalities for operation does the system provide?

How large can the systems be for the program to manage them?

Is the system protected against intruders?

What happens when the connection to the cloud is lost?

Which operating data is stored in the system?

We have answers to your questions

Our products and services have aroused your interest? Then we are happy to help!

Whether it's creating an offer or editing service specifications, designing different types of equipment, advising on the selection of pumps and switchgear, or just helping with hydraulic and control issues.

Feel free to contact your nearest sales office and make an appointment. We look forward to you!

Find the right contact for your question.