Powering Fluid Flow: Facts about Radial (Centrifugal) Pumps

Radial pumps, also known as centrifugal pumps, are a type of rotodynamic pump widely used in various industries to transport fluids by converting rotational energy into fluid flow. These pumps feature a design where fluid enters the center, or eye, of the impeller, which redirects the flow radially outward due to centrifugal force. In this article, we'll explore the structure, working principle, types, and applications of radial pumps.

Applications of Centrifugal Pumps

Centrifugal pumps are highly versatile, suitable for a wide range of industries and applications:

- Water supply: Used in municipal water supply systems, agriculture, and irrigation for efficient water transfer.

- HVAC Systems: Employed to circulate water in heating, ventilation, and air conditioning systems.

- Wastewater treatment: Used to transport and process water in wastewater treatment plants.

- Industrial processes: Essential industries like chemical manufacturing and food processing for moving liquids or chemicals.

- Power generation: Common in boiler feed applications and cooling water circulation in power plants.

Advantages and Limitations of Centrifugal Pumps

Advantages

- Efficient fluid handling: Ideal for applications that need consistent flow at moderate pressures.

- Wide range of applications: Versatile design accommodates a broad spectrum of liquids and operating conditions.

- Easy maintenance: Fewer moving parts comparted to other types of pumps, reducing maintenance needs.

Limitations

- Limed to moderate pressure: While efficient at moderate pressures, centrifugal pumps are less effective for extremely high-pressure requirements.

- Handling viscous fluids: Performance decreases when handling high-viscosity fluids, as centrifugal action relies on fluid velocity.

Centrifugal Pump: How it Works

A centrifugal pump imparts velocity to a fluid through rotation, then converts that velocity into fluid flow. Here’s how each component plays a role in this process:

1. Machine Assembly: A centrifugal pump is a mechanical assembly with components such as a pump shaft mounted on bearings, seals to prevent leaks, structural elements to withstand operational stresses, and replaceable wear surfaces for easy maintenance.

2. Rotation and Fluid Velocity: The impeller, the rotating part of the pump, transfers velocity to the liquid. As it spins, it accelerates the fluid outward from the center, creating centrifugal force.

3. Flow Creation: The casing (volute) captures the velocity generated by the impeller and directs the fluid to the pump’s discharge, converting the velocity into flow.

Structure and Design

A typical centrifugal pump has three main components:

- Impeller: The rotating element of the centrifugal pump that transfers energy from the pump’s motor to the fluid, increasing the fluid’s pressure and flow rate.

- Volute (casing): A curved, spiral shaped casing that collects and discharges liquid from a pump’s impeller. The main functions of the volute are to:

- Convert the fluid’s kinetic energy into potential (pressure) energy.

- Direct fluid from the impeller to the pump’s discharge point.

- Motor: The power source that drives the impeller’s rotation.

Image source: Wikimedia (adapted)-Centrifugal Pump

The impeller, mounted on a shaft that connects to the motor, rotates at high speeds. The impeller’s vanes are designed to exert centrifugal force on the incoming fluid, pulling it into the eye of the impeller and then expelling it outward through the volute.

Working Principle

A radial pump operates on the principle of centrifugal force. As the impeller rotates, the fluid entering through the eye of the impeller is pushed outward towards the along the vanes. This outward acceleration creates a pressure differential: low pressure at the suction inlet and high pressure at the discharge outlet. The action results in a steady flow, ideal for applications needing consistent flow and moderate pressure.

Image source: Wikimedia (adapted)-Centrifugal Pump Working Principle

A simple example of centrifugal force can be observed by stirring a glass of water. As you spin the water, it rises from the center and moves toward the edge of the glass. The faster you stir, the more forcefully the water is pushed outward, creating a flow and increasing pressure-an effect known as “head”. This rotation transfers energy to water, generating centrifugal forces that push the liquid outward, much like how centrifugal pumps move fluid through their system.

Image source: Wikimedia-Stirring in a glass of water

Types of Centrifugal Pumps

Centrifugal pumps are classified into several types based on design features and application requirements. Wilo offers all types of centrifugal pumps, except for the regenerative turbine:

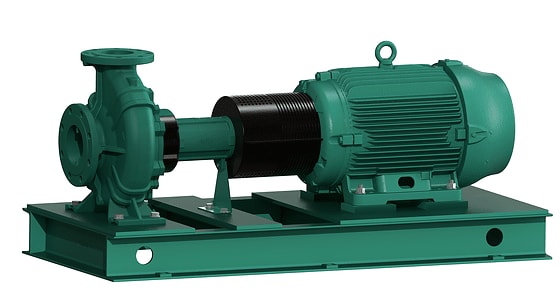

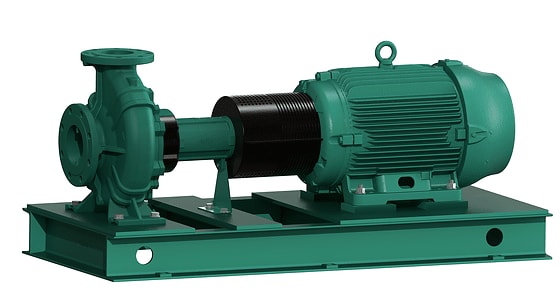

- Overhung Impeller Pumps: The impeller is mounted on the end of a shaft that is cantilevered or “overhung” from its bearing supports at the end of the pump casing. “End-suction” pumps are the most common type of overhung impeller pumps, however inline pumps will fall under this category as well. Examples of overhung impeller type pumps Wilo offers includes:

-

Wilo-FA

-

Wilo-NL-HE

-

Wilo-CronoLine-IL

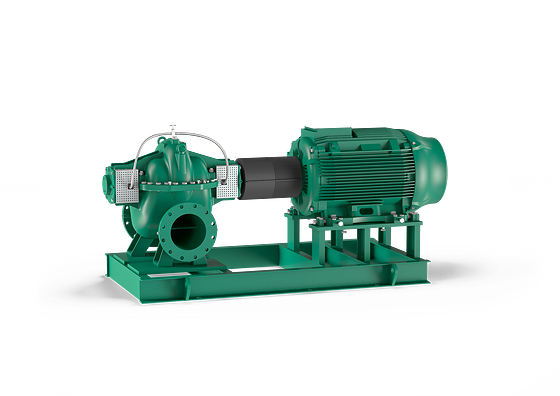

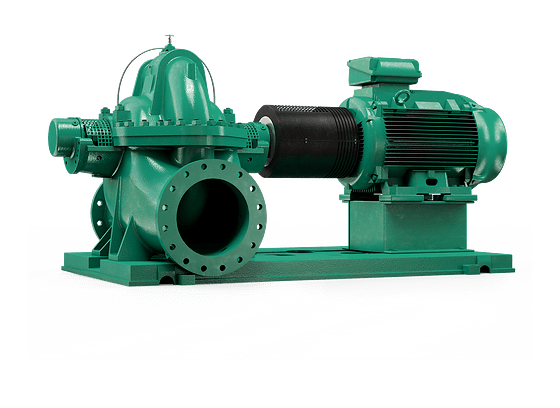

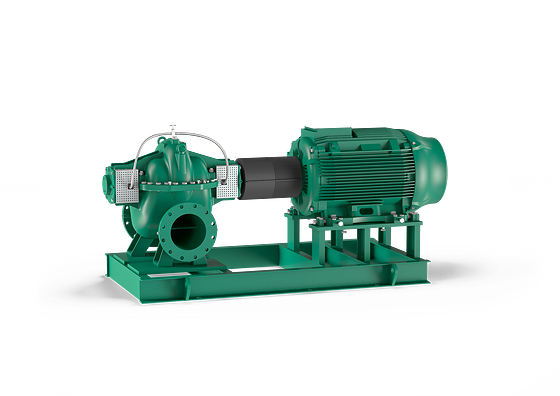

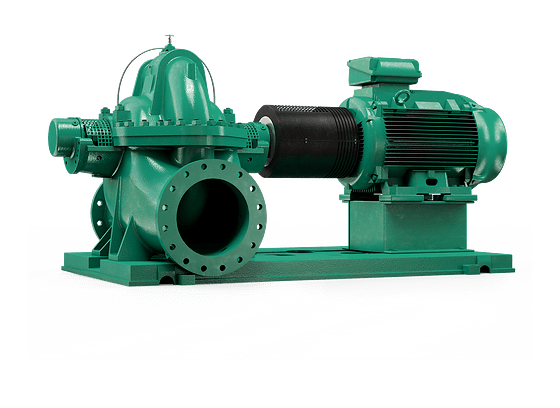

- Between the Bearings Pumps: The impeller(s) are mounted on a shaft with bearings at each end, positioned between the bearings for better stability under high-pressure conditions. Many between-the-bearings pumps are commonly called “split case” pumps, where the casing is split either axially (perpendicular or across) or radially across the shaft to allow easy access to internal pump parts for maintenance. Wilo offers two split case pumps, the Wilo-SCP and the Wilo-Atmos TERA-SCH-HE.

-

Wilo-Atmos TERA-SCH-HE

-

Wilo-SCP

- Vertically Suspended Pumps: The impeller is mounted on a vertically suspended shaft. Vertically suspended pumps are categorized based on their casing design and type, and mechanical configuration. Even though Wilo does not offer vertically suspended pumps in their portfolio, their partner brand, American Marsh Pumps does.

- Regenerative Turbine Pumps: These pumps use peripheral, or side channel, vanes or buckets manufactured with a rotating impeller to impart energy to the pumped liquid. These pumps are characterized by a low rate of flow and high head. Wilo does not offer these types of pumps.

- Circulator Pump: The circulator is a single-stage, overhung rotodynamic pumps designed to circulate water in systems with minimal head. Typical applications are hydronic heating or cooling and potable hot water recirculation to provide hot water on demand.

-

Wilo-Stratos MAXO

-

Wilo-Star E 21

-

Wilo-Z 15+

Summary

Radial (centrifugal) pumps are a reliable, efficient choice for fluid transfer across numerous industries. With their simple yet effective design, they handle a variety of flow and pressure requirements with ease. Understanding the specific needs of an application is essential to selecting the right type and configuration of a radial pump, whether it's for simple water supply or high-pressure industrial processes. To learn more about the classification of radial (centrifugal) pumps, visit The Hydraulic Institute.

Wilo is Your Solutions Provider

Wilo USA headquartered in Cedarburg, WI, is a multi-national pump manufacturer and one of the world’s leading premium suppliers of pumps and pumps systems for building services, water management, and the industrial sector. With innovative solutions, smart products, and individual services, Wilo is your solution provider in making water move using intelligent, efficient, and eco-friendly techniques. Wilo is a manufacturer of numerous types of radial (centrifugal) pumps. Discover our efficient pumps and pumps systems for a sustainable future or have a quick glance of the Wilo Product Guide.

November 2024 | tlk