A Flow of Differences: Open versus Closed Loop Piping Systems

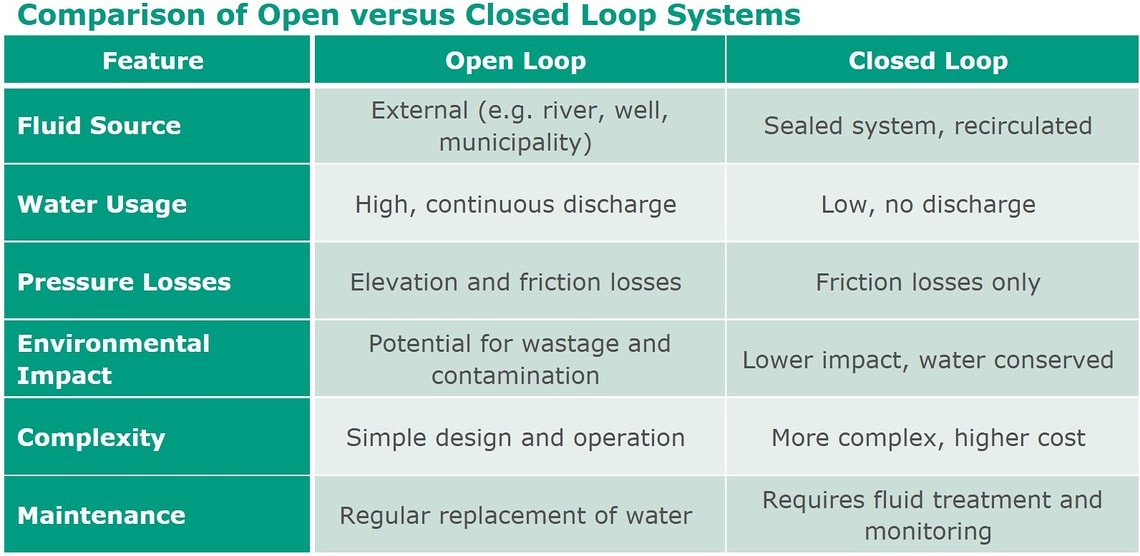

Open and closed loop piping systems are two fundamental approaches used for fluid circulation across various industries, each with its own advantages and drawbacks. While both systems are designed to transport and manage fluids such as water, they operate in distinct ways.

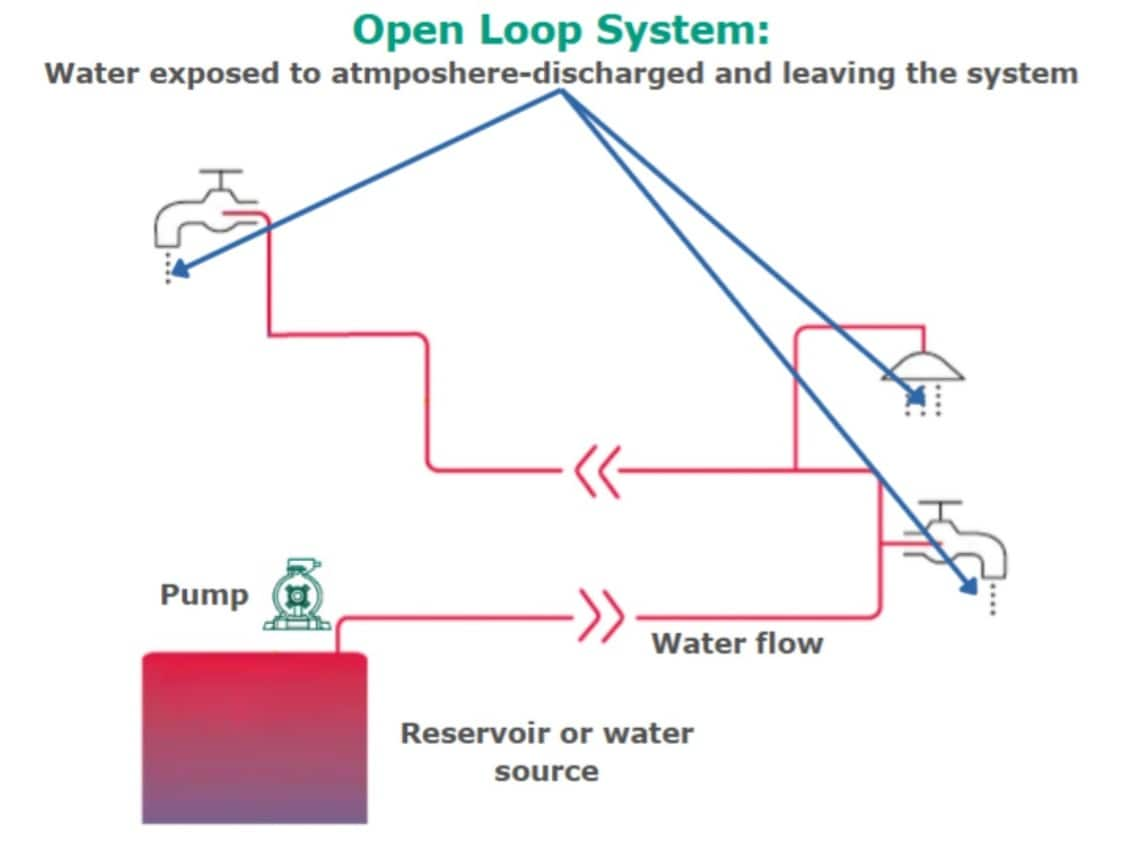

Open Loop Piping System

An open loop system is a fluid circuit in which the pumped fluid flows from an external source to its point of use and is then discharged, either back into the environment or to a drain. At some point in the process, the fluid is exposed to the atmosphere. This system operates in a single direction, with the fluid being used once and not recirculated.

A simple example of an open loop system is a garden hose. Water is drawn from the faucet (source) and is used to water plants, then discharged into the environment. The water does not re-enter the system (garden hose) and is exposed to the atmosphere.

How it Works:

- Water enters the system, passes through various components (like heat exchangers, pumps, etc.), and then exits the system through faucets, shower heads, toilets, etc.

- The water flows in one direction, from source to use where it is discharged and not reused.

- The water is replaced as it is lost or discharged from the system.

- The pump must overcome both elevation (static) and friction losses (head) to transport the water.

Applications

Open loop piping systems draw fluid from an external source, use it for a specific purpose, and then discharge the fluid. Common applications include:

- Municipal water distribution, where water is supplied to households and discharged as wastewater.

- Irrigation systems that source water from natural bodies to nourish crops.

- Industrial processes such as cooling, cleaning, or quenching.

These systems also play a role in hydroelectric power generation, cooling towers, and fire protection, where water is sourced, utilized, and released. Additionally, they are used in aquaculture to supply fresh water for fish farming and in decorative water features like fountains.

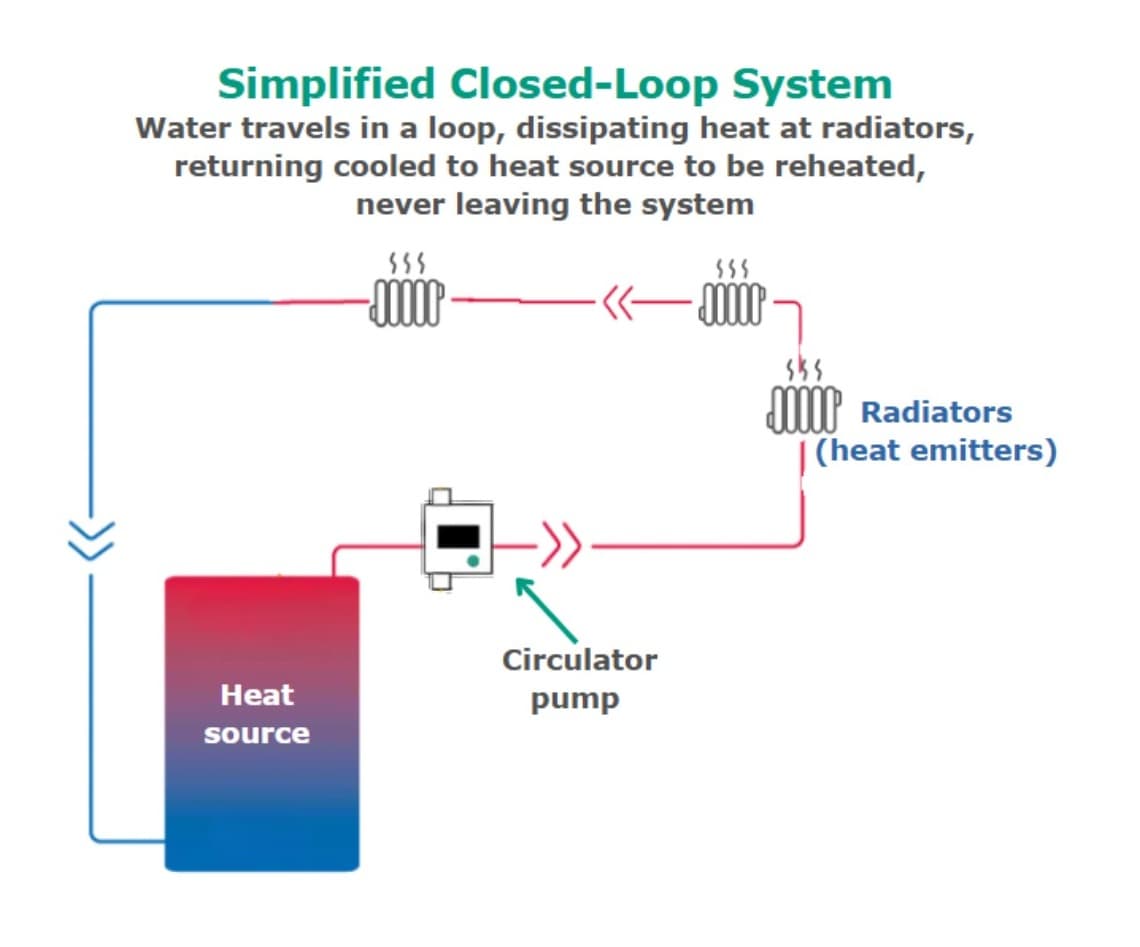

Closed Loop Piping System

In contrast, closed loop systems operate within a sealed circuit, where the fluid circulates continuously without exposure to the atmosphere. These systems recycle the fluid within the system, ensuring it is reused rather than discharged. Closed loop systems typically do not allow the fluid to enter or exit the system, except when necessary for maintenance or fluid replenishment.

A key feature of closed loop systems is they do not need to account for elevation (head) losses in total head (TH) calculations. The system is already pressurized, with no need to lift water against gravity. Instead, these systems only account for friction losses, meaning the pumps are designed to overcome friction losses generated from the system components (piping type, length, and dimension, number of valves and fittings, heat exchangers, etc.) rather than changes in pressure caused by elevation.

An example of a closed loop system is a building's chilled water system where the same chilled water is continuously circulated through the building to cool air conditioning units, before returning to the chiller for re-cooling.

How it Works

- The system is self-contained, with pumps circulating fluid in a continuous loop.

- Heat exchangers or other mechanisms are used to transfer or manage heat within the system.

- The fluid remains isolated from the external environment, maintaining its integrity throughout the process.

- The pump must overcome only friction losses (head) to transport the water.

Applications

Closed loop piping systems are widely used in applications where fluid needs to be recirculated without being lost or exposed to the environment. Here are some key areas where closed loop systems are used:

- HVAC Systems: In larger buildings or commercial applications, closed loop systems manage temperature and humidity efficiently, improving comfort and reducing energy usage.

- Geothermal Heating and Cooling: In geothermal systems, fluid circulates through underground pipes, absorbing heat from the ground in winter to heat buildings and transferring heat back to the ground in summer to cool them.

- District Heating and Cooling Systems: A closed loop system transfers heated or chilled water to multiple buildings through a network of insulated pipes, typically serving areas like cities, industrial parks, or university campuses to heat or cool them.

- Radiant Floor Heating Systems: Warm water flows through pipes embedded in floors, providing energy-efficient heating in both residential and commercial spaces.

- Solar Thermal Systems: Fluids in these systems circulate through solar collectors, capturing and transferring heat to a storage tank for use in heating water or spaces.

- Chilled Water Systems: These systems use recirculated chilled water to maintain consistent temperature control throughout buildings such as office complexes, data centers, and hospitals.

- Industrial Process Cooling: Closed loop systems are essential in various industries to efficiently cool machinery, equipment, or production processes, circulating water or other fluids to absorb heat and return cooled fluids for reuse.

- Cooling Systems for Electronics and Data Centers: Closed loop systems are crucial for regulating the temperature of sensitive equipment in data centers and server rooms by circulating coolant to absorb heat and maintain optimal temperatures.

- Heat Recovery Systems: These systems capture excess heat from industrial processes or equipment and transfer it for reuse, enhancing energy efficiency in plants, power stations, and renewable energy facilities.

Wilo is Your Solutions Provider

Wilo is your trusted solutions provider for cutting-edge pumping and water management systems. With a commitment to innovation, efficiency, and sustainability, Wilo delivers high-performance solutions tailored to meet the needs of diverse industries, from residential and commercial applications to large-scale industrial projects. Our advanced technologies, reliable products, and expert services ensure optimal fluid circulation, energy savings, and environmental responsibility. Whether you need energy-efficient pumps, custom systems, or technical support, Wilo is here to help you achieve your goals with unparalleled precision and reliability. Partner with Wilo and experience the future of fluid management today!

March 2025 | tlk