Boosting Efficiency

Vital Role of Pressure Boosters in Water Management

Water distribution is essential for clean water consumption, sanitation, manufacturing, and agriculture. To ensure water systems function properly, it is crucial to maintain adequate system pressure. Historically, gravity has been used to assist in water distribution. However, with factors such as increased housing development, larger and taller buildings, and expanding populations into areas with uneven terrain, maintaining consistent pressure at various points has become increasingly important. Consequently, pressure booster systems have been developed to sustain appropriate water pressure levels.

Key Functions

Pressure booster systems serve as the backbone of efficient water management by regulating pressure, maintaining consistent flow, and supporting critical operational processes. They ensure pumps operate at optimal efficiency, protect infrastructure from pressure fluctuations, and enable reliable delivery across high-service networks, lift stations, irrigation systems, and chemical dosing applications. By stabilizing system performance, pressure boosters enhance operational reliability, reduce maintenance needs, and contribute to sustainable water management practices.

- Maintain Consistent Flow: Boosters ensure wastewater moves efficiently through treatment stages, preventing stagnation or overflow.

- Support Treatment Efficiency: Proper pressure supports aeration, chemical dosing, and filtration processes, improving overall plant performance.

- Enable Pump Optimization: By balancing pressure, booster systems allow main pumps to operate closer to their best efficiency point (BEP), reducing wear and energy use.

- Compensate for Elevation Changes: Facilities with varying topography benefit from boosters that maintain pressure across high and low points.

- Protect Infrastructure: Prevents pipe surges and cavitation that can damage pumps, valves, and other equipment.

Benefits

By optimizing pump performance, protecting equipment, and supporting critical processes such as irrigation, chemical dosing, and lift station operation, pressure boosters enhance system efficiency, reduce energy consumption, and ensure reliable service. Their versatility makes them indispensable for maintaining operational stability and achieving sustainable water management outcomes.

- Optimized pump performance and energy efficiency

- Reduced equipment wear and maintenance costs

- Stable operation under varying flow demands

- Enhanced system reliability across diverse water management applications

Key Applications

Even though pressure booster systems are typically used for tall commercial and residential buildings to ensure higher floors have sufficient water pressure, pressure booster systems can play a vital role in ensuring consistent flow, maintaining operational efficiency, and supporting a wide range of water management applications. By regulating pressure and flow, these systems enhance performance, protect equipment, and enable reliable water delivery.

- High-Service Pumps: Maintain optimal pressure in municipal and industrial water distribution networks to ensure reliable delivery across varying elevations.

- Seal Water Systems: Provide controlled pressure to mechanical seals, preventing leaks and extending pump life.

- Source Water Transfer: Support efficient pumping from raw water sources to treatment facilities or storage reservoirs.

- Field Irrigation Systems: Ensure consistent water pressure for agricultural irrigation, improving crop yield and reducing water waste.

- Lift Station Assistance: Maintain steady pressure in lift stations systems, enabling smooth wastewater and stormwater transport.

- Chemical Dosing Support: Deliver precise pressure for chemical dosing systems, ensuring accurate treatment and regulatory compliance.

Identifying the Need for a Booster System

A pressure booster system is required whenever a water management application cannot maintain adequate pressure or flow using existing pumps and infrastructure. Key indicators include:

Insufficient Pressure at Critical Points

- Water does not reach upper floors in multi-story buildings or elevated areas.

- Flow at distant or high-elevation points drops below design requirements.

Long or Complex Piping Networks

- Extended pipelines or multiple branches cause pressure loss.

- System cannot sustain steady flow throughout the network.

Variable or High Demand

- Irrigation systems, industrial processes, or municipal networks with fluctuating water use require consistent pressure.

- Sudden demand spikes result in low pressure outputs or extended pump run times.

Support for Lift Stations and Transfers

- Booster systems assist in lifting water or wastewater to higher elevations or across challenging terrain.

- Ensures smooth operation of primary pumps without overloading them.

Critical Processes Requiring Precise Pressure

- Chemical dosing, filtration, aeration, or sensitive equipment operation depends on stable pressure.

- Inconsistent pressure can compromise treatment efficiency or operational safety.

Aging or Undersized Infrastructure

- Older systems may not meet current pressure requirements due to wear or increased demand.

- Boosters, in some instances, help modernize and optimize system performance without complete pipe repair or replacement.

Pressure boosters are more than auxiliary equipment—they are a critical component in maintaining efficiency, reliability, and sustainability in modern wastewater management systems.

Wilo is Your Solutions Provider

Wilo is your trusted solutions provider for water management and pressure booster systems, delivering innovative, reliable, and energy-efficient solutions for municipal, industrial, and agricultural applications. With decades of expertise in pump technology and system optimization, Wilo supports customers in maintaining consistent water pressure, protecting infrastructure, and improving operational efficiency. From high-service pumping and lift station assistance to irrigation and chemical dosing, Wilo’s comprehensive portfolio and engineering support ensure tailored solutions that meet the unique demands of every water management project.

Featured Products

-

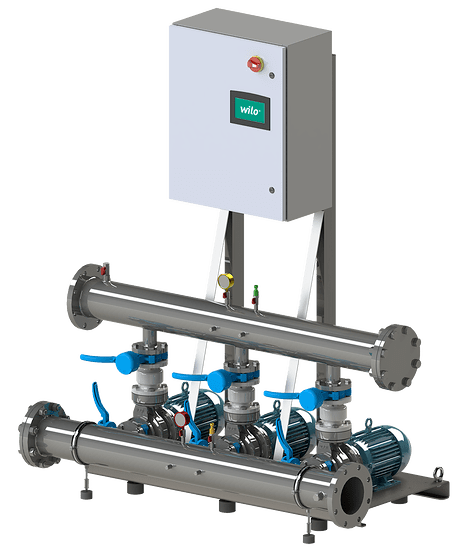

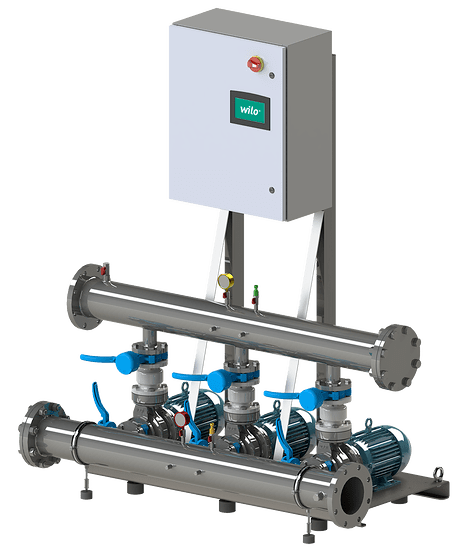

Wilo-WiBooster

-

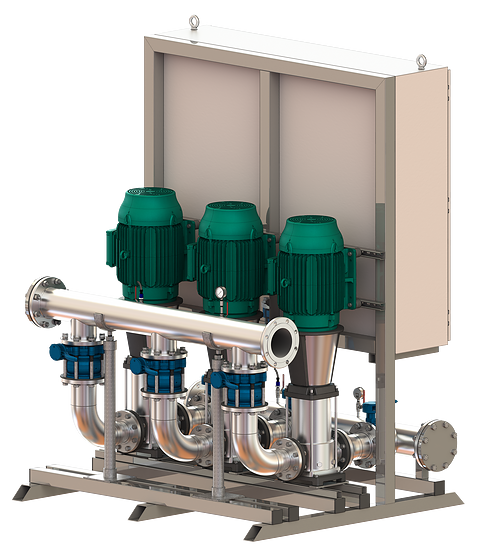

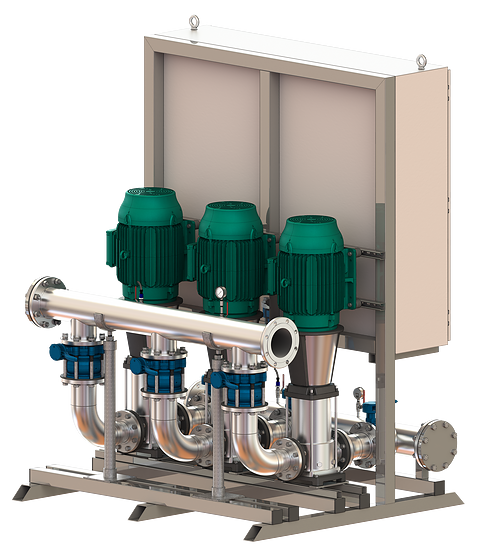

Wilo-CO MVI

November 2025 | tlk