Powering Fluid Flow: Key Facts About Circulator Pumps

Circulators are vital in HVAC systems, especially in hydronic heating and cooling. They move fluids through systems, either distributing or removing heat from a space, and the most efficient medium for moving heat energy. Found in residential, commercial, and industrial settings, modern models feature variable-speed motors and smart controls for enhanced performance and reduced operating costs. Understanding their function helps in selecting the right pump for optimal efficiency.

What are Circulators?

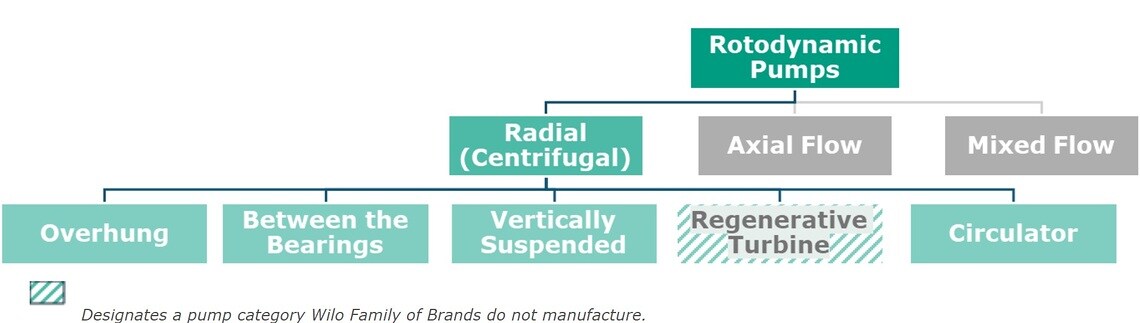

Circulators are single-stage centrifugal pumps designed to provide minimal head (pressure) to overcome pipe friction losses in which they are installed (Hydraulic Institute).

Circulators share similarities with overhung in-line pumps, featuring a centrifugal design with aligned suction (inlet) and discharge (outlet). However, the key difference between a pump and a circulator lies in their function and application. Circulators differ by having horizontal motors and being specifically engineered for water circulation and recirculation.

A circulator is a compact device commonly used in residential and light commercial hydronic heating and cooling, and hot water recirculation systems. Since these systems are already pressurized, the circulator’s motor only needs to maintain fluid movement without lifting water against gravity (head).

In contrast, pumps are typically larger and designed to move fluids to overcome both static (elevation) head and friction head, generating enough pressure to lift fluids from a lower to a higher point.

Circulators play a crucial role in maintaining heat and hot water availability in a building. In a home with a hydronic heating system, a circulator moves hot water from the boiler through pipes to radiators, underfloor heating systems, or baseboard heaters. As the heat dissipates and water cools, the circulator returns the fluid to the boiler for reheating, ensuring a continuous supply of warmth throughout the home. In a hot water recirculation system, the circulator keeps hot water flowing through the pipes, ensuring a continuous flow of hot water, reducing wait times for hot water at faucets and showers, saving both water and energy.

Components of a Circulator

Operating Principle

Like all centrifugal pumps, circulators operate based on the principles of centrifugal force. In a circulator, fluid is drawn into the suction inlet and then enters the impeller. As the impeller rotates, it imparts energy to the fluid, causing it to move radially outward, creating a low-pressure area at the eye of the impeller that continuously draws in more fluid. The fluid is then pushed outwards toward the outer edges of the impeller and exits at a higher pressure. The action results in a steady flow, ideal for applications needing consistent flow and moderate pressure.

Circulator Categories

Circulators are classified into two categories based on coupling type, close- and flexibly coupled.

Close-coupled circulators: Close-coupled circulators have an impeller that shares a common shaft with the motor, rather than 2 shafts coupled. The motor bearings absorb both axial and radial hydraulic loads. Close-coupled circulators are further classified based on rotor design:

Wet rotor:

- The motor shaft is immersed in the pumped fluid, which acts as a coolant and lubricant.

- Typically built with a two-piece design, making them maintenance-free.

- No air-cooling fan is needed, ensuring quieter operation.

Wet rotor pumps are also called sealless canned motor or glandless pumps because they have no mechanical seal that could leak fluid to the atmosphere, eliminating contamination of the fluid from an outside source. Wilo offers circulators with wet rotors including:

-

Wilo-Stratos MAXO

-

Wilo-Stratos MAXO-D

-

Wilo-Stratos MAXO-Z

-

Wilo-TOP-S

-

Wilo-Star E 21

-

Wilo-Z 15+

Dry rotor:

- A mechanical seal separates the fluid from the motor components, including the shaft.

- These pumps are repairable and have a long operating life.

- They use air-cooling fans mounted on the motor shaft.

Flexibly coupled circulators: In flexibly coupled circulators, the pump shaft has its own bearings that absorb hydraulic loads. Although the motor is connected directly to the circulator, the circulator’s impeller and driver shafts are flexibly linked. These circulators typically feature dry rotor designs and can have horizontal motors for various applications.

Key Applications of Circulators

Circulators are used in a variety of settings across residential, commercial, and industrial applications. Their primary role is to provide sufficient head (pressure) to overcome pipe friction losses in a pressurized system, making them versatile and essential in various industries.

- Residential: Circulate hot water in hydronic heating systems, including radiators, underfloor heating, and baseboard heaters, ensuring consistent heat distribution; provide instant hot water, reducing wait times at faucets and showers, and saving water and energy; and transfer heat collected by solar panels to storage tanks for indirect heating.

- Commercial: Distribute heated or cooled water for climate control in office buildings, hospitals, and hotels; and transport hot water across multiple buildings or zones for centralized heating.

- Industrial Processes: Regulate temperatures in manufacturing processes, production lines, and heat exchangers; and circulate fluids in geothermal systems for heating or cooling.

- Agricultural and Aquaculture Systems: Maintain water movement for irrigation, hydroponics, and fish tank systems to optimize conditions.

Advantages of Circulators

- Energy Efficiency: Designed for closed-loop systems, circulators require minimal power to overcome pipe friction, resulting in lower energy consumption. Modern models with variable-speed motors can optimize performance and reduce energy costs further.

- Improved Comfort: Ensure effective distribution of heat in hydronic systems, maintaining consistent indoor temperatures. Also provide instant hot water in recirculation systems, eliminating delays at faucets and showers.

- Water Conservation: By delivering hot water quickly, circulators reduce water wastage in plumbing systems.

- Quiet Operation: Wet rotor designs eliminate the need for air-cooling fans, resulting in quieter performance compared to dry rotor (mechanical seal) circulators.

- Compact and Versatile Design: Small size makes them easy to install in residential, commercial, and industrial systems. Compatible with various applications like HVAC systems, hot water recirculation, and solar and geothermal heating.

- Low Maintenance: Many models, especially wet rotor types, are designed for minimal servicing due to their simple and robust construction.

Conclusion

Circulators are vital for efficient heating, cooling, and water distribution in several applications. They ensure consistent temperature control, energy savings, and comfort. Modern advancements like variable-speed motors and specialized designs make them adaptable for residential and industrial needs. Understanding their operation and applications is key to optimizing performance and supporting sustainable energy and water use.

Wilo is Your Solutions Provider

Wilo is a trusted solutions provider for circulator pumps and HVAC (heating and cooling) applications, offering innovative, energy-efficient products designed to meet the demands of modern heating, cooling, and water circulation applications. With a focus on quality, reliability, and sustainability, Wilo provides a wide range of circulators tailored to residential, commercial, and industrial needs. Advanced features such as smart controls, variable-speed motors, and robust designs ensure optimal performance, energy savings, and long-term value. Whether you need solutions for hydronic heating, hot water recirculation, or complex HVAC systems, Wilo delivers cutting-edge technology and exceptional service to support your efficiency and comfort goals.