Powering Clean Water Delivery

Split Case Pumps in Water Management Applications

“Between the bearings”, or split case pumps, play a vital role in modern clean water management by delivering high-efficiency, high-flow performance for large-scale water movement. Their robust, horizontally split design allows for easy maintenance and long service life, key advantages for municipal water systems, treatment facilities, and distribution networks. With reliable operation and the ability to handle substantial volumes with minimal energy consumption, split case pumps help ensure consistent, clean water delivery while supporting utilities’ goals for sustainability, resilience, and operational efficiency.

What is a Split Case Pump?

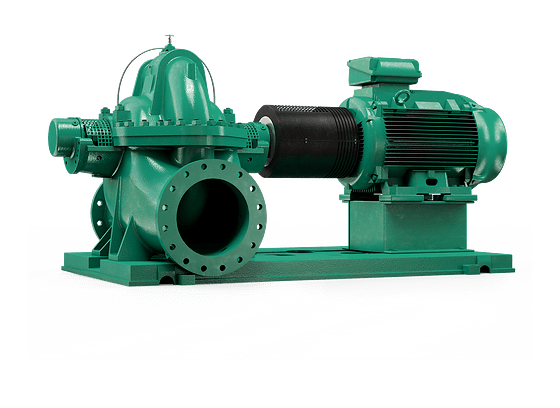

A split case pump is a centrifugal pump engineered for high-flow, continuous-duty operation, making it a primary asset in large-scale clean water systems. Its defining characteristic is the dual-suction, “between-the-bearings” impeller configuration (Image 1), in which the impeller is supported by bearings on both the drive and non-drive ends. This arrangement provides lower Net Positive Suction Head required (NPSHr), hydraulic balance, minimizes axial thrust, and significantly reduces shaft deflection, resulting in lower vibration levels and extended bearing and seal life. The hydraulically balanced design also enables the pump to deliver stable performance across a wide operating range, particularly in high-flow and high-pressure applications where overhung-impeller pumps may experience performance degradation.

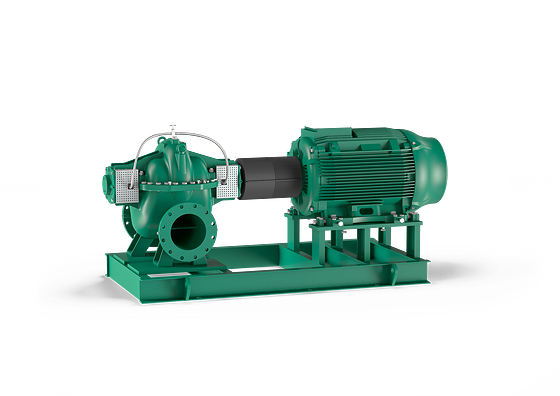

Additionally, the pump casing can be horizontally or vertically split along the shaft centerline (Image 2), allowing for direct access to the rotor assembly without disturbing suction or discharge piping. This split-case construction simplifies inspection, facilitates precision alignment during maintenance, and reduces downtime—critical advantages for utilities and facilities that operate continuous water transmission and distribution systems.

Where Split Case Pumps Are Used in Water Management

Split case pumps are widely used across the entire clean water cycle, including:

Raw Water Intake

- Moves large volumes of surface or groundwater from rivers, reservoirs, or wells.

- Provides the initial lift required for treatment processes.

Water Treatment Plants

- Transfers water through filtration, clarification, and disinfection stages.

- Supports stable flows for consistent treatment performance.

Finished Water Distribution

- Provides steady, high-capacity flow to municipal distribution networks.

- Maintains pressure levels required to serve residential, commercial, and industrial users.

Booster and Transmission Systems

- Overcomes long-distance pipeline friction and elevation changes.

- Ensures reliable pressure in large grids and regional water systems.

Why Split Case Pumps are Ideal for Clean Water Applications

Split case pumps are ideal for clean water applications due to their combination of high efficiency, long service life, ease of maintenance, and stable performance. Their dual-suction impeller design minimizes axial forces and hydraulic losses, resulting in excellent wire-to-water efficiency that supports utilities’ energy-reduction goals. Built for continuous, high-demand operation, these pumps feature rugged construction, low bearing loads, and balanced hydraulics that significantly extend operating life. Maintenance is streamlined through the horizontally split casing, which allows direct access to internal components without disconnecting suction or discharge piping—reducing downtime and service costs for critical 24/7 water systems. In addition, split case pumps provide reliable performance at high flow rates, maintaining smooth, consistent pressure across varying system demands and ensuring dependable water delivery.

Role in Clean Water Solutions

Split case pumps play an essential role in supporting safe, reliable, and sustainable water delivery:

- Ensuring supply reliability: High flow capacity keeps municipalities supplied even during peak demand or emergency events.

- Protecting water quality: Stable flows reduce hydraulic fluctuations that can affect treatment stages.

- Promoting sustainability: High efficiency contributes to lower energy consumption and reduced operational carbon footprint.

- Building system resilience: Proven designs help water utilities meet long-term reliability and infrastructure goals.

Applications Benefiting from Split Case Pump Technology

- Municipal drinking water systems

- Water treatment plant process pumping

- Transmission mains and regional water grids

- Commercial or industrial large-scale supply systems

- Irrigation districts and agricultural water delivery

- Cooling water circulation for utilities and manufacturing

Wilo is Your Solutions Provider

Split case pumps are a cornerstone of modern clean water infrastructure. Their high efficiency, dependable performance, and service-friendly design make them essential for delivering safe, clean, and sustainable water to communities and industries around the world.

At Wilo, we build on these strengths with engineered pump solutions that combine proven hydraulics, advanced materials, and smart control technologies to meet today’s demanding water management challenges. Whether supporting municipal distribution networks, treatment facilities, or large-scale industrial systems, Wilo delivers the reliability, expertise, and innovation needed to keep clean water flowing—now and into the future.

Featured Products

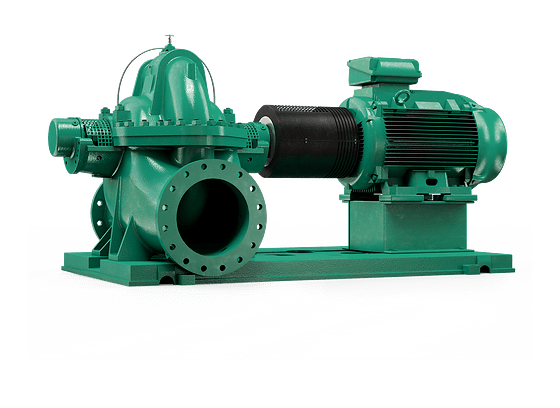

-

Wilo-SCP

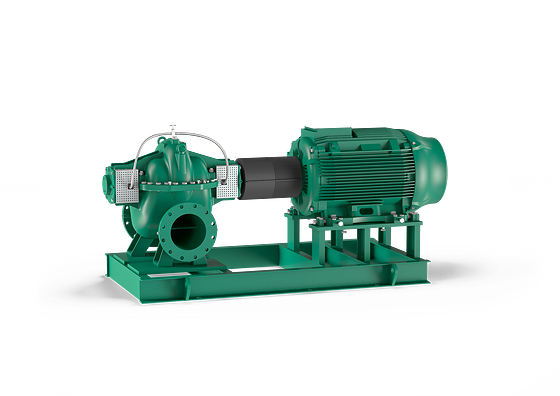

-

Wilo-Atmos TERA-SCH-HE

December 2025 | tlk