Geared for Success

Factsheet on Submersible Mixer Drives

Submersible mixers work to impart a certain amount of energy or energy into wastewater, or media, to keep solids suspended in a tank. A driver, or motor, is needed to create that thrust in conjunction with a propeller. The drives convert electrical energy from a motor into rotational motion for the mixer’s propeller. The propeller’s rotation generates thrust to create fluid flow, suspend solids, and ensure even mixing.

Types of Drives

The drive impacts how much horsepower (HP) and in turn thrust is delivered, how efficiently the motor operates, and what type of mixing applications the system can handle. Two primary types of drives are utilized in submersible mixers: direct drive and planetary gear drives.

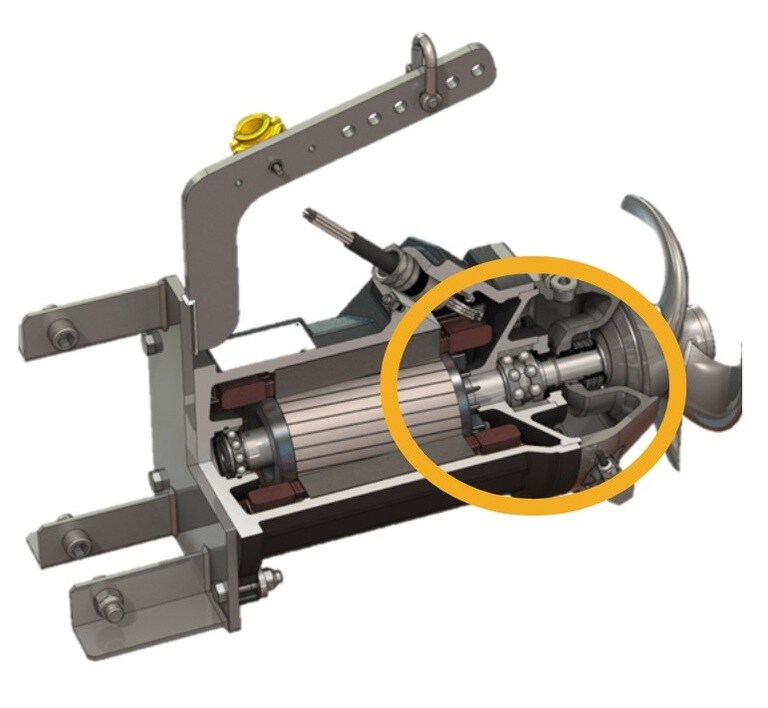

Components of a Submersible Mixer

Direct Drive: A direct gear drive transmits power from the motor straight to the propeller, without any intermediate components such as planetary gears. Essentially, the propeller is connected to the motor shaft, allowing the motor’s rotation to directly turn the propeller.

In a direct-drive system, the propeller rotates at the same speed as the motor, since there is no gear reduction. This design offers several advantages in smaller type basins, including high efficiency. Direct-drive submersible mixers are ideal for pump pits and smaller to medium-sized tanks or applications that require high mixing power.

Planetary Gear Drive: A planetary gear drive is a set of gears that allows a submersible mixer to reduce a motor’s high speed prior to the propeller into a controlled, high-toque rotation, making it possible to mix heavy or viscous liquids differently.

Planetary gear drives provide high torque in a compact size, ideal for heavy-duty mixing in large tanks. The gears are durable and balanced, with the torque distributed among the gears. Planetary gear drives provide smooth operation with less vibration, making them quieter than most other gear systems. They also multiple gear ratios, which allow a wider range of input HP at the propeller to appropriately match the applications’ needs. Lower speed mixers are favorable in wastewater treatment applications to protect the microbes needed for water treatment, such as in anoxic basins/zones, anaerobic basins/zones, swing basins/zones, and circulation basins.

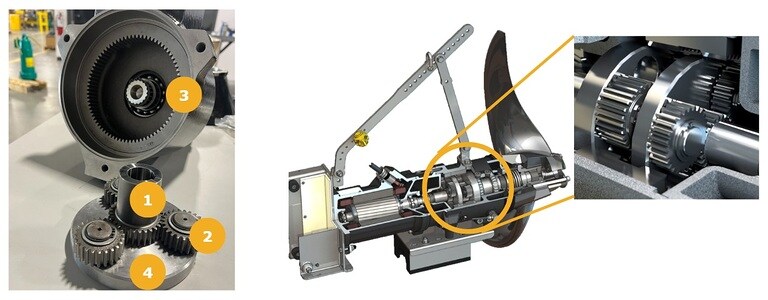

A planetary gear system has four main components:

1.Sun gear: The central gear driven by the motor.

2. Planet gears: Several smaller gears that rotate around the sun gear.

3. Ring gear: An outer gear with internal teeth that meshes with the planet gears

4. Carrier: Holds the planet gears and transfers torque to the output shaft.

This arrangement resembles a solar system, which is why it is called “planetary”.

How it works: The motor turns the sun gear, which rotates the planet gears around it. The planet gears mesh with the ring gear and the carrier, which becomes the output. This arrangement allows the drive to multiply torque while reducing speed, depending on which gear is fixed or used as the input.

Differences between Direct Gear Drive and Planetary Gear Drive

| Feature | Direct Gear Drive | Planetary Gear Drive |

|---|---|---|

| Mechanism | Single-stage gears directly transmit power from motor to propeller | Multiple gears (sun, planet, ring) distribute power through planetary arrangement |

| Complexity | Simple design, fewer parts | More complex, with multiple gears and moving parts |

| Torque Handling | Moderate torque capability | High torque capability even at low speeds |

| Speed Reduction | Limited ratio (motor speed to propeller speed) | Can achieve large reduction ratios in a compact space |

| Efficiency | High, power goes through fewer gears and components | Slightly lower due to multiple gear contacts, but still efficient |

| Maintenance | Easier and cheaper to maintain | More maintenance needed due to more components |

| Size and Weight | Typically, lighter and more co more compact for the same power | Can be bulkier but allows smaller motors for same torque output |

| Applications | Moderate-thrust mixers or where simplicity is preferred | High-thrust mixers, heavy-duty applications, or where space is limited but high torque is needed |

In Summary:

The choice between a direct drive and a planetary gear drive, while both are robustly designed, comes down to the application’s requirements. Direct drive mixers offer high efficiency mixing in smaller basin or sumps. Planetary gear drives, on the other hand, deliver superior torque and versatility, making them ideal for heavy-duty, high-viscosity mixing, or for medium to larger sized basin. Understanding these differences ensures you select the right drive for optimal mixer performance, energy efficiency, and long-term reliability.

Wilo is Your Solutions Provider

Wilo USA headquartered in Cedarburg, WI, is a multi-national pump manufacturer and one of the world’s leading premium suppliers of pumps and pumps systems for building services, water management, and the industrial sector. With innovative solutions, smart products, and individual services, Wilo is your solution provider in making water move using intelligent, efficient, and eco-friendly techniques.

Wilo manufactures a wide range of centrifugal pumps and submersible mixers, including the Wilo-Flumen OPTI-TR, Wilo-Flumen EXCEL-TRE, and Wilo-EMU TR(E) 216-326 lines. For more information regarding Wilo’s submersible mixers, how to size them, and other sustainable solutions, visit the Wilo USA website or take a quick look through the Wilo Product Guide for more options.

September 2025 | tlk