Below the Waterline

Submersible Recirculation Pumps at Work

What is a Recirculation Pump?

The recirculation pump is a variant of a submersible mixer. In wastewater treatment, a recirculation pump is used to move treated or partially treated wastewater from one stage of the process back to an earlier stage. This recirculation enhances treatment efficiency, improving mixing, and helps meet effluent quality standards.

How do Recirculation Pumps Work?

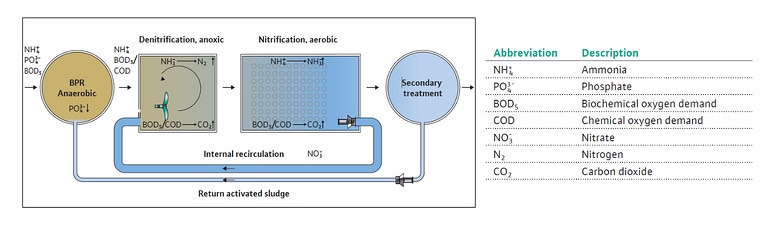

A recirculation pump uses a rotating impeller to add energy to wastewater, creating flow and pressurethat move liquid through piping from one process zone to another. The pump draws liquid, such as return-activated sludge or mixed liquid, into its suction side. As the impeller spins, it accelerates the liquid and directs it through the discharge piping back into the process, such as from the clarifier to the aeration tankor from the aeration basin to the anoxic zone (biological treatment process where oxygen is absent, but nitrate and nitrite are present). By continuously circulating sludge and mixed liquid, recirculation pumps maintain the right concentrations of microorganisms, support denitrification, and keep the biological process in balance.

Key Functions

Recirculation pumps play a vital role in maintaining process stability and treatment efficiency in wastewater plants.

Returned Activated Sludge (RAS)

- Pumps settled sludge from the secondary clarifier back to the aeration tank.

- Keeps biomass concentration steady, improving biological treatment efficiency.

Internal Mixed Liquid Recirculation (MLR)

- Transfers mixed liquid from the aeration basin to anoxic zones.

- Supports denitrification by providing nitrate-rich water for nitrogen removal through

- multiple treatment stages.

- Improves oxygen utilization in aeration basins through recirculation.

Sludge/Waste Sludge Recirculation

- Helps thicken sludge and balance solids loading in clarifiers and digesters.

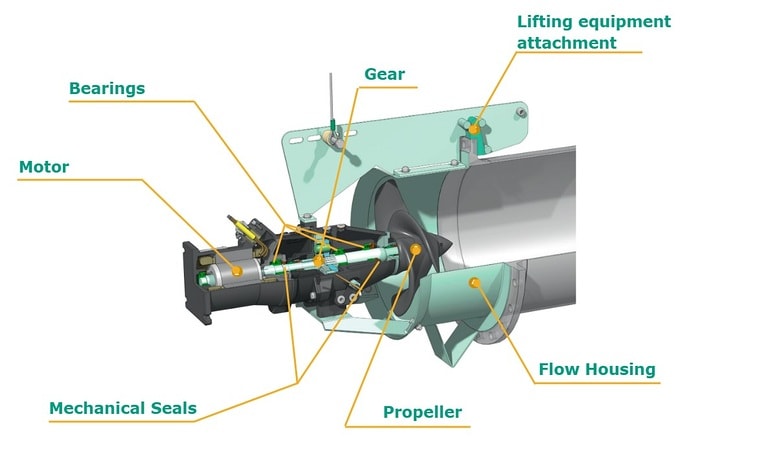

Main Components of a Recirculation Pump

Submersible motor, pump housing, gear, and impeller form a compact unit for recirculation pumps. This design makes it possible to modify the pump exactly to the required technical data.

Differences Between Recirculation Pumps and Submersible Mixers

Recirculation pumps and submersible mixers play very different roles in a wastewater treatment plant. A recirculation pump transfers liquid from one location to another, such as returning activated sludge from the clarifier back to the aeriation tank or moving mixed liquid into an anoxic zone. Its purpose is to create a directed flow between process stages.

In contrast, submersible mixers do not move water from one tank to another. Instead, it creates circulation in a single basin. Mixers keep solids suspended, prevent settling, and ensure uniform conditions for biological treatment.

Both the submersible recirculation pump and the mixer are essential in wastewater treatment. Together they form a complementary system that ensures efficient, reliable wastewater treatment, but their functions are not interchangeable.

Key Differences

| Features | Recirculation Pump | Submersible Mixers |

|---|---|---|

| Main Function | Transfers liquid from one location to another | Creates circulation within a single tank or basin |

| Flow Type | Produces net flow from Point A to Point B | Produces internal circulation, no net transfer of liquid |

| Performance Metric | Flow rate (gallons per minute) | Thrust (N) and mixing intensity |

| Applications | Returned activated sludge, mixed liquid recirculation, sludge loops | Keeping solids suspended, preventing settling, homogenizing tank contents |

| Design | Flow Housing + Motor + propeller mounted directly in the liquid | Motor + propeller mounted directly in the liquid |

| Installation | Always submersible | Always submersible |

| Standards | ISO 21630 | ISO 21630 (mixers, thrust-based selection) |

| Key Benefit | Enables biological process balance by moving sludge/liquid between zones | Maintains uniform tank conditions and prevents dead zones |

Best Practices

To get the best performance from recirculation pumps, it is important to follow a few best practices.

- Pumps should always be sized to match the required flow and head-oversized pumps waste energy and can upset process balance, while undersized pumps may not meet treatment needs.

- Using variable frequency drives (VFDs) allows operators to adjust recirculation rates to match changing plant conditions, improving both efficiency and process stability.

- Regular maintenance of impellers, seals, and bearings helps prevent clogging and premature wear, while redundancy (duty/standby pumps) configurations provide reliability in case of pump failure.

- Monitoring sludge return-ratios and flow patterns to avoid over- or under-circulation, ensuring the biological process remains balanced, supporting consistent nutrient removal and high effluent quality.

Recirculation pumps are vital to the biological treatment process in wastewater plants. By moving sludge and mixed liquid strategically, they help maintain process balance, improve nutrient removal, and ensure compliance with stringent water quality standards. Proper sizing, selection, and operation of these pumps directly influence plant performance, operating costs, and sustainability.

Wilo is Your Solutions Provider

Wilo USA, headquartered in Cedarburg, WI, is a global leader in pumps and mixing systems for building services, water management, and the industry. With a focus on intelligent, energy-efficient, and eco-friendly solutions, Wilo helps municipalities and industries reduce operating costs while improving sustainability.

Wilo is more than just a pump manufacturer, Wilo is your partner in creating efficient, reliable, and sustainable wastewater solutions. Our recirculation pumps, the Wilo-Flumen EXCEL-RZPE 50-60 and the Wilo-Flumen OPTI-RZP 50-80, are designed to keep treatment processes running smoothly, with rugged construction, smart controls, and energy-saving technology that deliver performance you can trust. From returned activated sludge to mixed liquid recirculation, Wilo provides the right solution for every stage of your plant. With Wilo at your side, you get more than equipment-you get confidence, innovation, and support every step of the way.

September 2025 | tlk