The Foundation for Reliable Flow: Base-Mounted Overhung Pumps

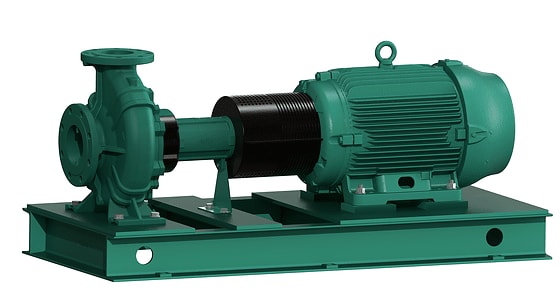

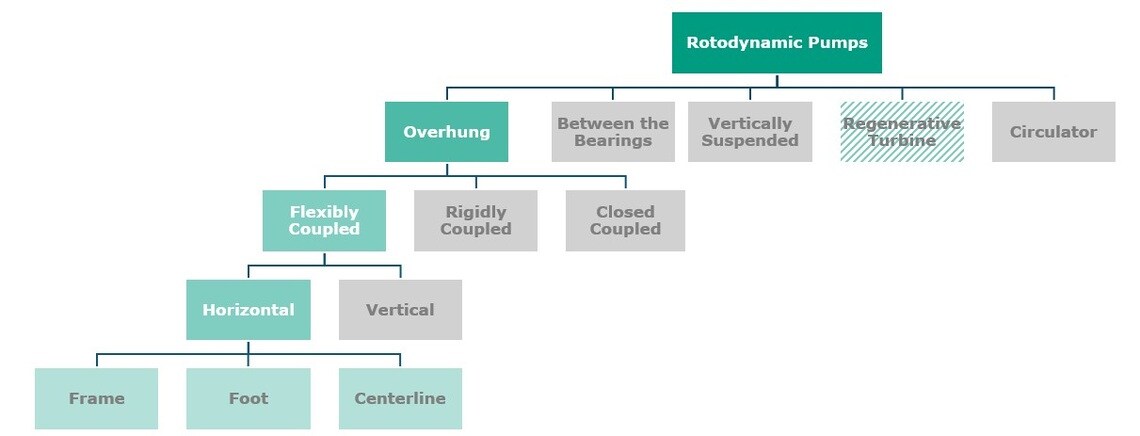

Base-mounted pumps are an overhung, flexibly coupled horizontal centrifugal pump. This design allows for a degree of misalignment between the pump and driver, enhancing durability and operational flexibility. Unlike other overhung pumps, base-mounted pumps feature the pump and motor mounted on a shared support structure, typically a baseplate, providing stability and alignment.

Key Characteristics of Flexibly Coupled Base-Mounted Pumps

- Two separate shafts for the pump and driver, joined by a flexible coupling to compensate for misalignments.

- Mounted on a base plate (or foundation) for stability, shaft alignment, and easy installation.

- Designed to tolerate slight misalignment and absorb vibrations during operation.

- Incorporates an internal bearing housing to handle all hydraulic loads generated by the pump.

- Horizontal configuration with the shaft positioned parallel to the ground.

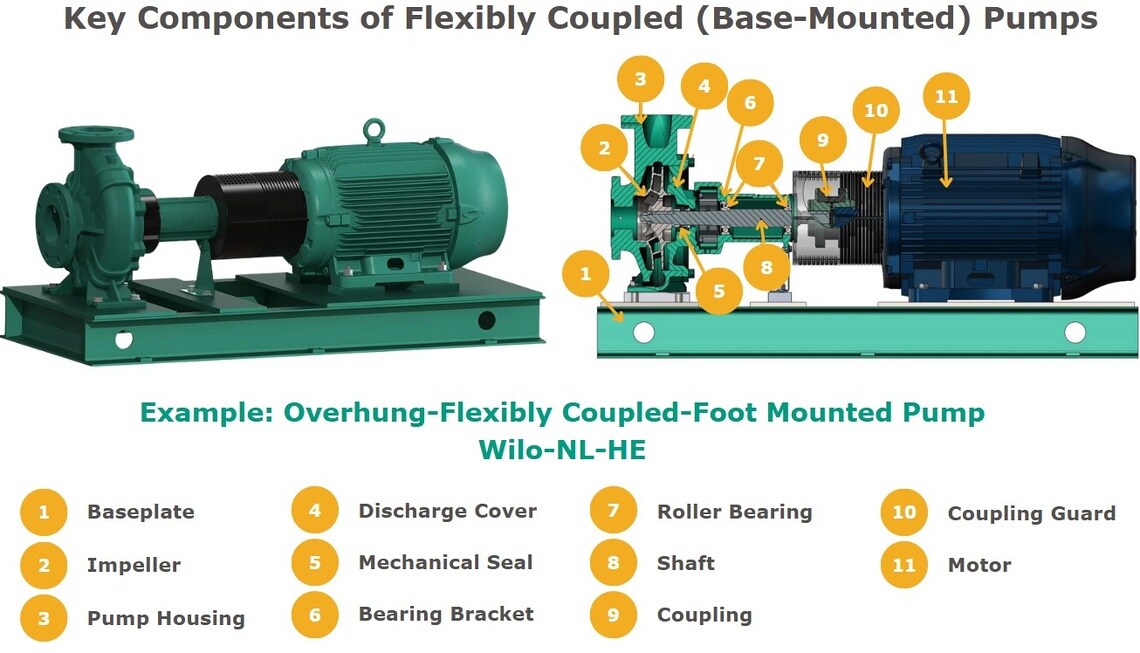

Components of a Base-Mounted Pump

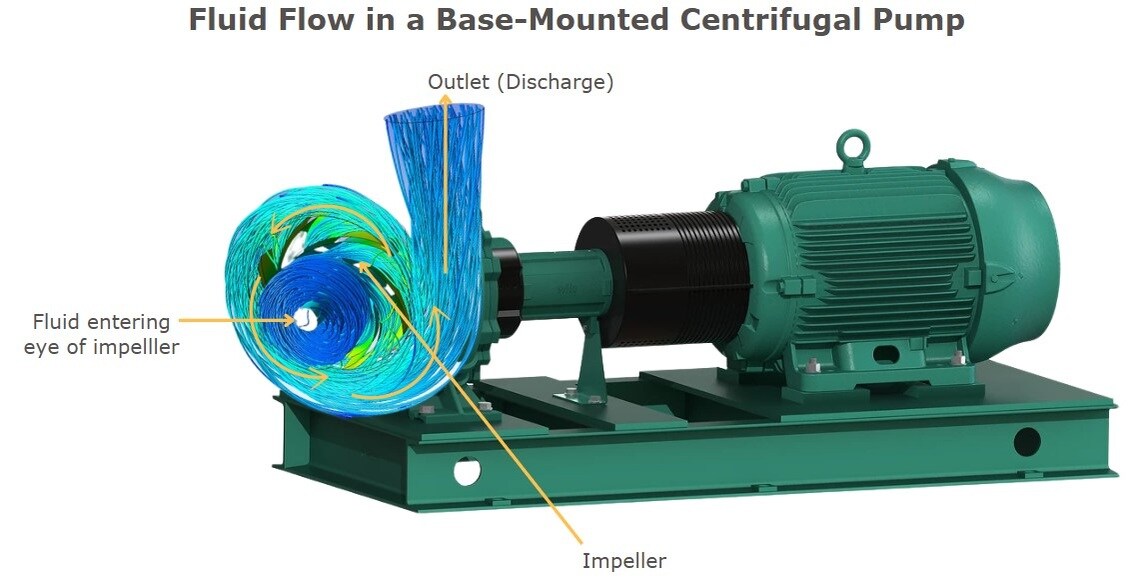

- Casing: Houses the impeller and directs the fluid flow.

- Impeller: Creates the fluid motion; typically overhung and supported by one end of the shaft.

- Shaft and Bearings: Transmit rotational energy to the impeller and provide support.

- Coupling: Flexible design compensates for misalignment between the pump and driver shafts.

- Seals: Prevent leakage along the shaft.

- Baseplate: Provides a rigid foundation to securely hold the pump and drive in position, minimizing vibration and movement during operation.

Flexible Coupling in Base-Mounted Pumps

Flexible couplings are commonly used in base-mounted pumps and are typically constructed with a rubber material sandwiched between two metal hubs. These couplings connect the motor to the pump end while allowing for slight flexion or bending movement. The rubber insert in the coupler provides critical protection:

- Motor Bearings Protection: Reduces damage caused by pump-induced forces.

- Pump Protection: Minimizes motor-induced damage, especially in variable-speed systems where torque is inconsistent (e.g., HVAC applications).

Flexible couplings act as a sacrificial component, designed to fail under excessive stress to protect more expensive components like shafts and bearings. They compensate for misalignments caused by factors such as:

- Shaft deflection

- Thermal expansion

- Installation inaccuracies

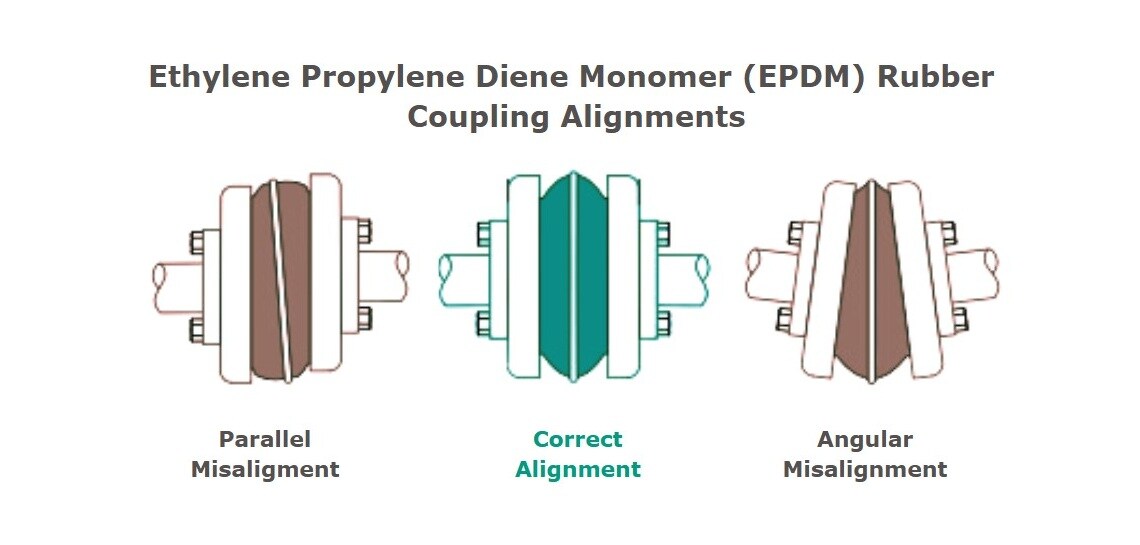

A flexible coupling helps compensate for various types of misalignments that occur during typical operation, as shown below:

However, couplings do not fix misalignment, and pump and motor shafts should be aligned. Couplings are designed to transmit a limited amount of torque before they transfer radial and axial loads to the bearings, shafts, and other affected machine parts. Flexible coupling allows for a small tolerance of misalignment, usually within a few hundredths or thousandths of an inch of millimeter, depending on the design, manufacturer’s specifications, and type of misalignment.

Parallel misalignment occurs when the pump and motor shafts are offset but remain parallel. When shafts are parallel misaligned, they can cause uneven wear on bearings and excessive vibrations. Flexible couplings absorb the offset to maintain smooth operation.

Angular misalignment occurs when the pump and motor shafts are not parallel and form an angle at the coupling. The centerlines of the pump and the motor shafts diverge, increasing stress on the coupling and shafts, leading to potential damage. A flexible coupling bends slightly to compensate for angular deviations.

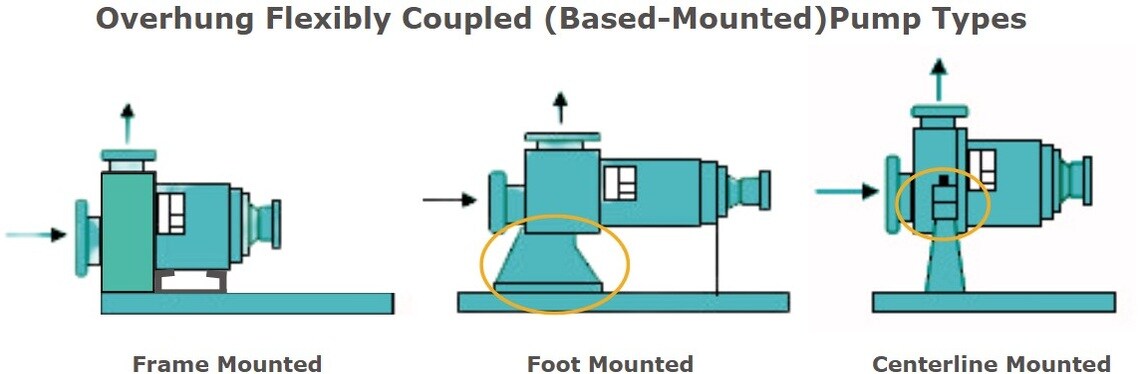

Types of Base-Mounted Pumps

The base-mounted (or flexibly coupled) overhung pumps can be categorized based on their support structure: Frame, Foot, and Centerline mounted pumps.

- Frame-mounted Pumps: In frame-mounted pumps, both the pump and driver are mounted on a common, dedicated baseplate. The pump has its bearing housing to support the shaft.

- Foot-mounted pumps: In the foot-mounted pump, the pump’s casing is bolted to the baseplate or foundation via “feet” on the bottom of the casing.

- Centerline mounted pumps: In a centerline mounted pump, the pump casing is supported along the casing centerline, rather than the bottom of the casing in the case of the base- and frame-mounted pumps.

Operating Principle

Like all centrifugal pumps, base-mounted pumps operate based on the principles of centrifugal force. In a base mounted pump, fluid is drawn into the suction inlet and then enters the eye of the impeller. As the impeller rotates, it imparts energy to the fluid, causing it to move radially outward, creating a low-pressure area at the eye of the impeller that continuously draws in more fluid. The fluid is then pushed outwards toward the outer edges of the impeller and exits at a higher pressure.

Key Applications of Base-Mounted Pumps

Base-mounted pumps, known for their stability and durability, are widely used across various industries for tasks requiring reliable fluid handling in heavy duty operations. Below are key applications categorized by industry:

- Industrial applications such as chemical processing and petrochemical and gas, and oil.

- Water Management in both municipal water supply and wastewater treatment.

- Power Generation from boiler feed pumps, cooling water circulation, and turbine systems

- HVAC systems, including heating and cooling applications and district heating systems.

- Food and Beverage industry with process water handling and cleaning systems

- Mining and Construction dewatering and slurry transport.

- Pharmaceutical and Biotechnology pure water systems and chemical handling.

- Marine ballast water systems, cooling, and firefighting.

Advantages of Base-Mounted Pumps

The advantages of base-mounted pumps include structural stability provided by the rigid and durable platform; ease of maintenance due to access to the pump without disturbing the driver or piping; and in some cases, handle thermal expansion, reducing operation risks.

- Structural Stability: Baseplate mounting provides a rigid and durable platform.

- Ease of Maintenance: Flexibly coupled designs allow easier disassembly of the pump without disturbing the driver or piping.

- Compact Footprint: Overhung impellers reduce the overall size of the pump compared to double-bearing designs.

- Thermal Compensation (Centerline): Centerline-mounted designs handle thermal expansion better, reducing operational risks.

- Versatility: Suitable for a wide range of applications in industries such as oil and gas, chemical processing, and water treatment.

- Cost-Effective: Fewer bearings and simplified construction reduce initial and operational costs.

Conclusion

Base-mounted pumps are versatile and reliable for diverse fluid handling applications. Their robust design, alignment flexibility, and vibration absorption ensure stability, efficiency, and durability in industrial, commercial, and municipal uses. Ideal for HVAC, water management, and process industries, these pumps deliver consistent performance, minimize downtime, and support productivity and sustainability.

Wilo is Your Solutions Provider

Wilo is your trusted solutions provider for base-mounted pumps in the building services, water management, and industry market segments. Renowned for its innovative engineering and commitment to sustainability, Wilo offers high-performance base-mounted pump solutions tailored to meet the unique demands of modern infrastructure. In building services, Wilo pumps ensure efficient heating, cooling, and water circulation for commercial and residential buildings, delivering energy savings and reliable performance. In water management, Wilo provides robust solutions for municipal water supply, wastewater treatment, and irrigation systems, ensuring consistent operation even in challenging environments. With advanced technology, customized designs, and a focus on reliability, Wilo empowers customers with efficient, durable, and sustainable pumping solutions.

May 2025 | tlk

Featured Products

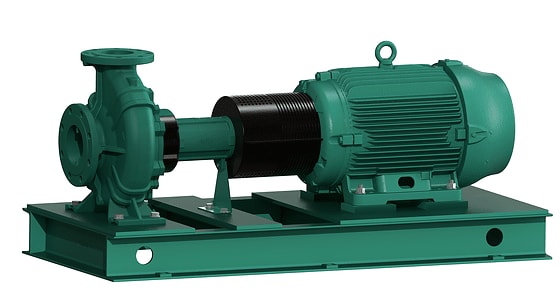

-

Wilo-NL-HE

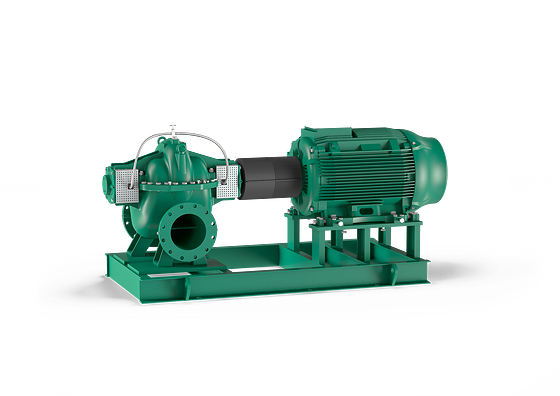

-

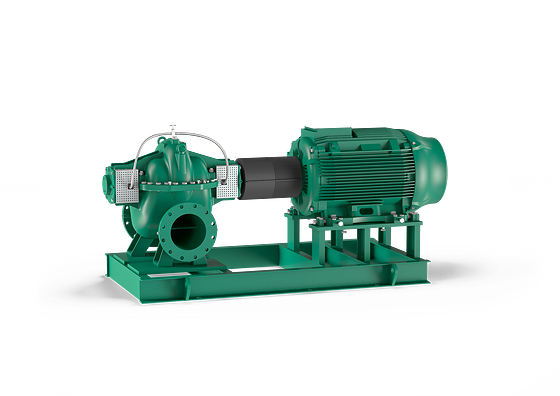

Wilo-Atmos TERA-SCH-HE

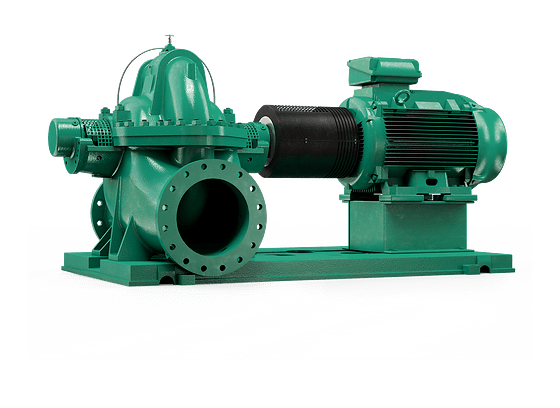

-

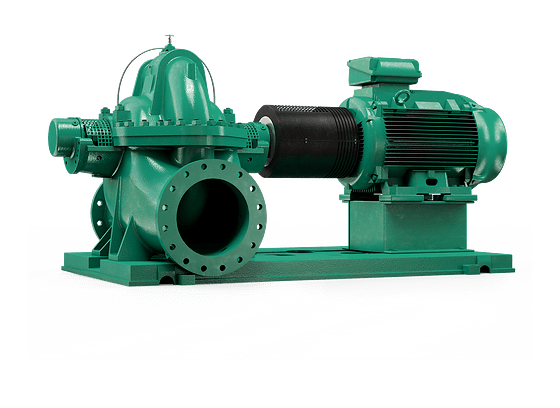

Wilo-SCP