Wilo-Isar MODH1-E-1

High-quality pressure-boosting system with a compact design

High-quality pressure-boosting system with a compact design

Integrated protection functions enable the Wilo-Isar MODH1E to provide reliable water supply for various applications at all times. The protection functions include overload protection, dry-running protection and low-water cut-out switchgear with automatic deactivation.

Furthermore, significant energy savings are achieved through pressure-loss-optimised hydraulics as well as optimal load adjustment.

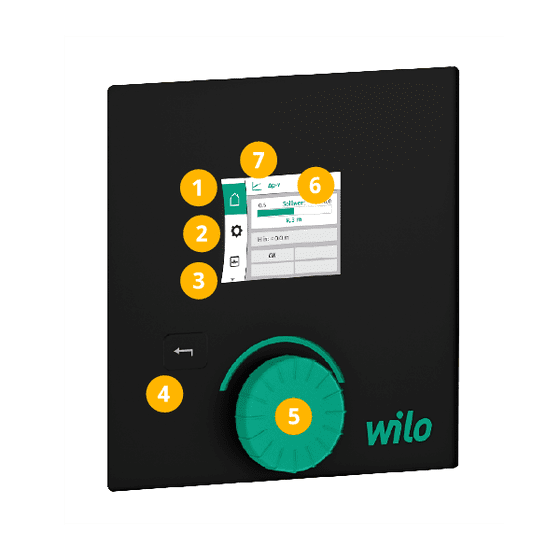

The colour display enables optimal operating convenience by displaying plain text.

Recommended services

Your advantages

- Compact system with a multistage stainless steel high-pressure multistage centrifugal pump from the Medana CH3-LE series with integrated air-cooled frequency converters with a large control range

- Efficiency class IE5 and variable differential pressure Δp-v enable high efficiency

- Colour display with plain text, simple navigation and settings via rotary knob ensure easy installation and operation

- Integrated safety features like low-water cut-out switchgear (WMS) provide a high degree of operational reliability

- Quick integration into building automation via optional CIF module

- Components that come in contact with the fluid are suitable for drinking water applications.

Design

Pressure-boosting system with one non-self-priming stainless steel high-pressure multistage centrifugal pump

Application

- Fully automatic water supply and pressure boosting in inlet mode, either from the public water supply network or from a tank, for domestic, commercial, industrial and municipal applications (e.g. residential, office, administration buildings, hotels, hospitals, trades, industry, water supply companies).

- Pumps drinking water, process water, cooling water or other industrial water, which does not affect the materials used, neither chemically nor mechanically, and does not have any abrasive or long-fibre constituents.

Equipment/function

- 1 Medana CH3-LE pump per system

- Components that come in contact with the fluid are corrosion-resistant

- Electrogalvanised base frame with height-adjustable oscillation absorbers for insulation against structure-borne noise

- Stop valve on every pump on the suction and discharge sides

- Non-return valve, on the discharge side

- Pressure sensor, on the end pressure side

- Pressure gauge optional, on the suction side

- Pressure gauge, on the end pressure side

- Low-water cut-out switchgear

- Control via integrated frequency converter

Typekey

Example: | Wilo-Isar MODH1-E-1-CH3-LE-204-EM-HS |

Isar | Multistage pressure-boosting system |

MOD | Commercial series |

H | Pressure-boosting system with horizontal pumps |

1 | Product level (1 = entry, 3 = standard, 5 = premium) |

E | Electronic frequency control |

1 | Number of pumps |

CH3-L | Pump series |

2 | Rated volume flow [m3/h] of the single pump |

04 | Number of single pump stages |

EM | Single-phase version |

HS | With main switch |

Technical data

- Mains connections:

- 3~400 V ± 10%, 50 Hz;

- 3~380/440 V ±10%, 60 Hz;

- depending on type also 1~230 V, 50/60 Hz (other versions on request)

- Max. fluid temperature: 50 °C (70 °C optional)

- Max. ambient temperature: 40 °C

- Operating pressure: 10 bar

- Inlet pressure: 6 bar

- Nominal connection diameter for end pressure side: R 2"/DN 100

- Nominal connection diameter inlet side: R 2"/DN 100

- Protection class: IP54

- Fuse on mains side: A, AC 3 according to motor power and EVU regulations

- Approved fluids (other fluids on request): Approved fluids are generally waters which do not attack the materials used, neither chemically nor mechanically, and do not contain any abrasive or long-fibre constituents.

- Cooling water

- Drinking and process water

Materials

Single pump:

- Impellers, stage chambers and pump housing made of stainless steel 1.4301/1.4404

- Shaft of stainless steel 1.4404

- EPDM gasket (EP851)/FKM (Viton)

- Mechanical seal made of tungsten carbide/carbon

- Bearing of tungsten carbide

- Pump support foot made of aluminium

Construction

- Base frame: electrogalvanised and with height-adjustable oscillation absorbers for comprehensive insulation against structure-borne noise; other versions on request

- Pipework: complete pipework made of stainless steel, suitable for the connection of all piping materials used in building services; the pipework dimensions must correspond to the overall hydraulic performance of the pressure-boosting system.

- Pump: One pump from the Medana CH3-LE series 2.., 4.., 6.., 10.., 16..; all pump components that come in contact with the fluid are made of 1.4301/1.4404 stainless steel.

- Valves: each pump is equipped on the suction and discharge side with a stop valve or with annular shut-off valves and a discharge-side non-return valve.

- Diaphragm pressure vessel: 8 l/PN 10 on the end pressure side with butyl rubber diaphragm, completely safe according to the food safety regulations; ball valve and drain and throughflow fitting according to DIN 4807 for test and inspection purposes

- Pressure sensors: 4 to 20 mA, one each on the suction and end pressure sides for pressure control by the integrated frequency converter.

- Pressure indication: Pressure gauge (ø 63 mm) on the end pressure side; additional digital display of the end pressure in the graphics display of the pump

- Controller: the control of the system is realised by the frequency converters integrated in the pump

Scope of delivery

- Factory-mounted, pressure-boosting system ready for connection and checked for functionality and impermeability

- Installation and operating instructions

- Factory test protocol