Understanding Overhung Pumps Key Features, Applications, and Advantages

Overhung pumps are a widely used type of centrifugal pump, characterized by their unique structural design, which enables them to handle various industrial applications effectively. Unlike other types of pumps, the impeller in an overhung pump is mounted on the end of a shaft that is supported by bearings on one side. This "overhung" design simplifies maintenance and enhances operational efficiency, making these pumps ideal for industries like chemical processing and water treatment.

What is an Overhung Pump?

An overhung pump is a type of centrifugal pump where the impeller is mounted on the end of a shaft that is cantilevered or “overhung” from its bearing supports at the end of the pump casing. In this design, the shaft is supported by bearings located outside the casing, on one side only. Overhung pumps are typically single-stage pumps, meaning they have a single impeller and can move fluids effectively without requiring complex configurations. This design provides various operational and maintenance advantages, such as easier access to components during maintenance.

Types of Overhung Pumps

Overhung pumps are primarily classified based on their coupling method. Coupling refers to how the pump and its driver (motor) are connected. Coupling affects alignment, maintenance, space requirements, and the overall performance of the pump.

Structure and Design

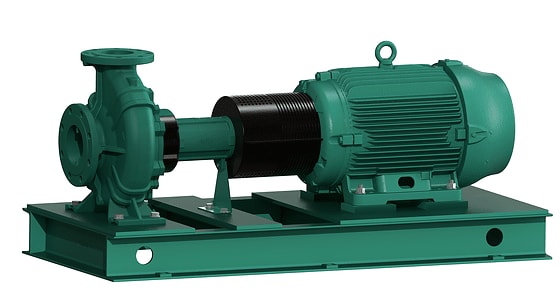

Flexibly Coupled: A flexibly coupled pump is one where the pump and driver shafts are connected by a flexible coupling that allow for some degree of misalignment between the pump and driver.Flexibly coupled pumps and their motors are mounted on the same support structure, such as a baseplate. Flexibly coupled pumps are characterized by:

- Two separate shafts for the pump and driver.

- Internal bearing housing to absorb all pump hydraulic loads.

- Pump tolerates slight misalignment and vibrations.

- Common in industrial applications requiring higher reliability.

Rigidly (Short) Coupled: In a rigidly (or short) coupled pump, the pump and motor are connected by a rigid coupling that does not allow for any movement or misalignment betweenthem. Rigidly coupled pumps are characterized by:

- Two separate shafts for the pump and driver.

- Requires precise alignment. Drive is aligned and assembled directly to the pump with machined fits.

- Driver bearings absorb all pump axial thrust loads and residual radial loads.

- Used in high-torque, space-constrained applications.

Close Coupled: In a closed coupled pump, the pump and motor are mounted together in a single unit, thus the pump’s impeller is directly mounted on the motor shaft. This design eliminates the need for a separate coupling or alignment between the pump and motor. Close coupled pumps are characterized by:

- One common shaft is shared between the pump and driver.

- The driver bearing absorbs all pump thrust loads.

- The driver is aligned and assembled directly to the pump with machined fits.

- Compact and cost-effective.o Best for light-duty and low-maintenance applications.

Sub-Classifications of Overhung Pumps

Overhung pumps can be further classified based on their configuration into horizontal, vertical, and submersible types:

Each configuration offers unique benefits, enabling overhung pumps to serve a broad range of industrial and commercial applications.

- Horizontal Overhung Pumps: Feature a horizontal shaft, suitable for installations with ample floor space and easy maintenance access. They are commonly used in industrial applications where ease of maintenance and accessibility are priorities.

- Vertical Overhung Pumps: Have a vertical shaft, saving floor space and fitting well in tight areas like water treatment plants or sumps.

- Submersible Overhung Pumps: Operate fully submerged, making them ideal for wastewater, drainage, and flood control, with a sealed design for protection against fluids and contaminants.

Some pumps can be installed horizontally or vertically, depending on their design and application requirements. Always consult the manufacturer’s Installation and Operation Manual (IOM) for proper installation guidelines. The configurations highlighted above are specific to Wilo brand pumps. For additional configurations and sub-categories, refer to the Hydraulic Institute’s resources.

Key Applications of Overhung Pumps

Overhung pumps serve a wide range of industrial and commercial applications due to their versatility and compact design. Key applications include:

- Water and Wastewater Treatment: Efficiently pumps clean water, wastewater, and sludge.

- Chemical Processing: Handles corrosive and hazardous fluids with specialized materials.

- Oil and Gas: Manages high-temperature hydrocarbons in refineries and petrochemical plants.

- HVAC Systems: Circulates water and fluids in heating, ventilation, and air conditioning systems.

- Food and Beverage: Suitable for fluid handling in food processing due to compact design.

Advantages of Overhung Pumps

Overhung pumps are chosen for their numerous advantages, making them suitable for applications requiring high efficiency, durability, and ease of maintenance. Some key benefits include:Water and Wastewater Treatment: Efficiently pumps clean water, wastewater, and sludge.

- Compact Design: Space-saving, ideal for confined installations.

- Ease of Maintenance: Easy access to components reduces downtime.

- Versatility: Suitable for a wide range of fluids and conditions.

- Cost Efficiency: Low lifecycle costs due to efficient performance and easy servicing.

- Mounting Flexibility: Can be installed horizontally or vertically as needed.

Conclusion

Understanding the classifications of overhung pumps helps in selecting the right pump for specific industrial needs. By considering factors such as coupling type, shaft orientation, design standards, and application requirements, industries can choose pumps that offer optimal performance, reliability, and ease of maintenance. Whether for chemical processing, water treatment, or general fluid handling, overhung pumps provide versatile, cost-effective solutions tailored to a wide range of operational demands.

Featured Products

-

Wilo-NL-HE

-

Wilo-CronoLine-IL

Wilo is Your Solutions Provider

Wilo is a trusted global solutions provider specializing in advanced water management and pumping systems. With decades of engineering expertise, Wilo delivers innovative, energy-efficient solutions tailored to various industries, including water supply, HVAC, and industrial processes. Wilo’s portfolio includes high-performance centrifugal pumps designed for reliability, durability, and optimal efficiency. Backed by cutting-edge technology and exceptional customer support, Wilo ensures seamless fluid handling solutions that drive sustainability and operational excellence.

Scot Pump, A Wilo Brand, is a leading manufacturer of high-quality OEM pumps, specializing in close?coupled (overhung) centrifugal pumps. With a strong focus on reliability and performance, Scot Pumps designs pumps that excel in demanding industrial and commercial applications. Scot products are engineered for efficiency, durability, and ease of maintenance, making them the preferred choice for OEM solutions. Backed by Wilo’s global expertise and commitment to innovation, Scot Pumps delivers industry?leading pumping systems tailored to meet your exact specifications.