Wilo-Actun ZETOS

Efficient raw water intake for all fields of applications

Efficient raw water intake for all fields of applications

The Wilo-Actun ZETOS is our versatile solution for efficient raw water intake, from municipal water supply to agriculture and mining. With a best-in-class pump efficiency of up to 86 %, the ZETOS is ideal for energy-efficient water supply in virtually all processes. The tough stainless steel investment casting and the robust design guarantee a long service life and a sustainable high efficiency, especially in difficult conditions, i.e. a high sand content of up to 150 g/m3.

Recommended services

Your advantages

- Energy-saving water supply with a pump efficiency of up to 86%

- Cost-efficient operation, thanks to the highest overall efficiency in this class with permanent magnet motor

- High reliability as a result of the particularly corrosion-resistant hydraulics made completely of 1.4408 (AISI 316) stainless steel investment casting

- High wear resistance: Max. sand content of up to 150 g/m³

- ACS approval for use with drinking water

- Straightforward maintenance, easy installation and dismantling

Eco-friendly features

- The use of high-quality materials ensures long service life – even in mining applications

- Efficient pump hydraulics and permanent magnet motors enable high CO₂ savings

- Increased reliability thanks to service-friendly design and optional Ceram CP coating

- Sustainable and carbon-neutral production and processes in our European factories

Design type

Multi-stage stainless-steel investment-casting submersible pump in sectional construction for vertical and horizontal installation.

Application

- Boreholes and cisterns

- Sprinkling and irrigation

- Ground-water lowering

- Pressure boosting

- Off-shore installations

- Fire-extinguishing systems

- Geothermal energy and thermal applications

- Underground mining

Liquid

For pumping in the following commercial areas:

- Drinking water (ACS approval, motor-dependant)

- Industrial water with max. sand content up to 150 g/m³

- Sea water

Equipment/function

- With or without integrated non-return valve

- NEMA coupling up to nominal motor size of 8"

- Wilo standard connection starting at nominal motor size of 10"

Typekey

Example: | Wilo-Actun ZETOS-K8.130-17 + NU 711-2/130 |

Hydraulics | Actun ZETOS-K8.130-17 |

Actun | Product family |

ZETOS | Series made of stainless steel investment casting |

K | Pump type |

8 | Diameter of the hydraulics in inches |

130 | Volume flow in m³/h at the best efficiency point at 50 Hz |

17 | Number of hydraulic stages |

Motor | NU 711-2/130 |

NU | Submersible motor |

711 | Size:

|

2 | Number of poles |

130 | Motor-dependant definition:

|

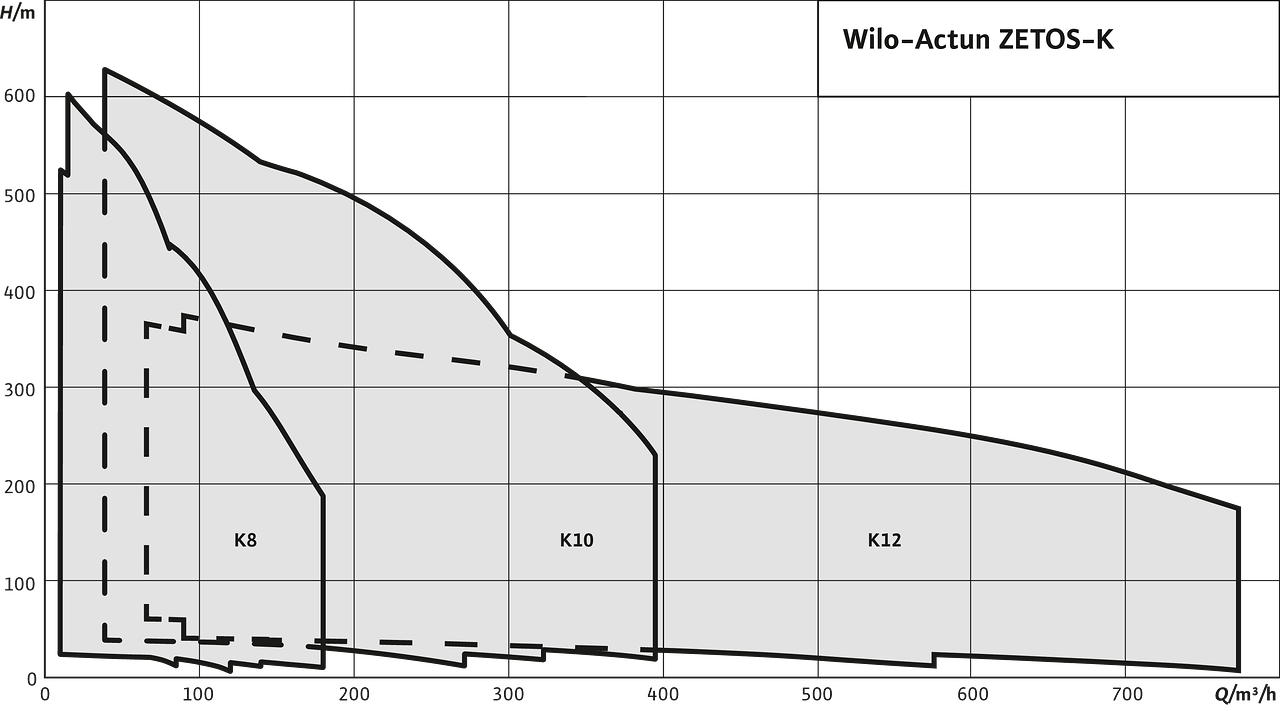

Technical data

Hydraulics

- Max. volume flow: 765 m³/h

- Max. delivery head: 640 m

- Max. fluid temperature: 70 °C

- Max. sand content: 100 g/m³ (K12), 150 g/m³ (K8, K10)

- Discharge port

- K8: G 5, DN 100/PN 10/16, DN 125/PN 10/16, DN 150/PN 10/16

- K10: G 6, DN 150/PN 10/16, DN 150/PN 40

- K12: 8-8 NPT, DN 200/PN 10/16, DN 200/PN 25, DN 200/PN 40

Motor

- Mains connection: 3~400 V, 50 Hz ±10 %; 3~460 V, 60 Hz ±10 %

- Max. fluid temperature: 60 °C, depending on motor type and flow velocity at the motor

- Submerged operating mode: S1

- Max. number of starts:

- NU 5 ..., NU 6 ..., NU 7 ... = 20/h

- NU 8 ..., NU 9 ..., NU 122 ... = 10/h

- NU 160 = 5/h

- Max. immersion depth:

- NU 5 ..., NU 711 = 350 m

- NU 6 ..., NU 701, NU 8 ..., NU 9 ..., NU 12 ..., NU 16 ... = 300 m

- IP rating: IP68

- Control range for frequency converter:

- Asynchronous motors: NU 501, NU 701 = 30 ... 50 Hz

- Asynchronous motors: NU 611, NU 801, NU 811, NU 911, NU 122, NU 160 = 25 ... 50 Hz

- Permanent magnet motors: NU 512, NU 612, NU 711, NU 812 = 60 ... 100 Hz

- After consultation with the manufacturer, motors can also be operated at higher frequencies!

Construction

Hydraulics

Multi-stage submersible pump with semi-axial hydraulics. Housing parts and impellers made of stainless steel investment casting (1.4408). Discharge port with threaded or flange connection available with or without integrated non-return valve. Motor connection as standard NEMA connection (up to 8") or standard Wilo connection (from 10").

Motor

Asynchronous and synchronous motors can be selected as the drive:

- Asynchronous three-phase AC motors for direct and star-delta starting:

- NU 501, NU 701: Hermetically sealed motor with enamel-insulated winding, resin-impregnated

- NU 611, NU 811, NU 911, NU 122, NU 160: Rewindable motor with insulated PE2 or PVC winding

- Operation on the frequency converter is permitted!

- Synchronous three-phase permanent magnet motor for direct starting:

- NU 512: Hermetically sealed motor with enamel-insulated winding, resin-impregnated

- NU 612, NU 711, NU 812: Rewindable motor with insulated PE2 winding

- A frequency converter is absolutely necessary!

Motor shroud made of steel, stainless steel or bronze casting. Hydraulic connection as standard NEMA connection (up to 8") or standard Wilo connection (from 10"). The motor shaft is sealed with a mechanical seal made of solid silicon carbide material. The motor bearings are self-lubricating. The thrust bearing is equipped with rockers to absorb the high axial thrust. The counter-thrust bearing absorbs the negative axial thrust.

Motors in the NU 5 … and NU 7 … series are filled with a water-glycol mixture. All other motors are filled with a water-glycerine mixture.

Cooling

- The motor is cooled by the pumped fluid. The motor must always be immersed.

- The limit values for maximum fluid temperature and minimum flow velocity must be adhered to.

- Vertical installation is possible with or without cooling shroud.

- In horizontal installation, the unit is supported by bearing blocks. An anti-vortex plate or cooling shroud may be used to improve the inlet flow.

Scope of delivery

- Unit (hydraulics system + motor) pre-assembled at the factory

- Connection cable per customer request

- Installation and operating instructions

Options

- Special voltages

- Higher fluid temperatures

- Flange adapter to accommodate different connection sizes

- Drinking water as motor filling (T version)

- Version with pressure shroud for the direct installation of the unit in the pipeline system. Standard models are without mounted non-return valves. The maximum inlet pressure is 10 bar.

Accessories

- Cooling shrouds

- Pressure shroud

- Bearing brackets and anti-vortex plate

- Transitions

- Switchgears

- Frequency converter

- Output filter

- Plastic cable connector set