Wilo-CronoNorm-NLG

Wilo-CronoNorm-NLG

Your advantages

- IE3/IE4 motor technology for energy-saving operation

- Optimised efficiency reduces life cycle costs

- Bidirectional, force-flushed mechanical seal

- Exchangeable neck rings

- Permanently lubricated, generously sized ball bearing

- Low NPSH value, optimal cavitation characteristics

Recommended services

Eco-friendly features

- Improved hydraulics ensure high overall efficiency and an IE3/IE4 motor saves energy

- Easily replaceable and standardised components for a longer service life (e.g. spacer coupling, bronze neck ring)

nlg__bigdut_01

Design type

Single-stage, low-pressure centrifugal pump with axial suction, mounted on a baseplate.

Application

- Pumping of heating water (acc. to VDI 2035), chilled water and water/glycol mixtures without abrasive substances in heating, chilled water and cooling systems.

- Applications for irrigation, building services, general industry, power stations, etc.

Equipment/function

Single-stage low-pressure centrifugal pump in monobloc design with coupling, coupling guard, motor and baseplate

- Mechanical shaft seal or stuffing box

Typekey

Example | NLG 200/315-75/4 |

NLG | Series designation: Standard pump |

200 | Nominal diameter DN of pressure port |

315 | Nominal diameter of impeller [mm] |

75 | Rated motor power P2 [kW] |

4 | number of poles |

Technical data

- Permissible temperature range -20°C to +120°C

- Mains connection 3~400 V, 50 Hz

- IP rating: IP55

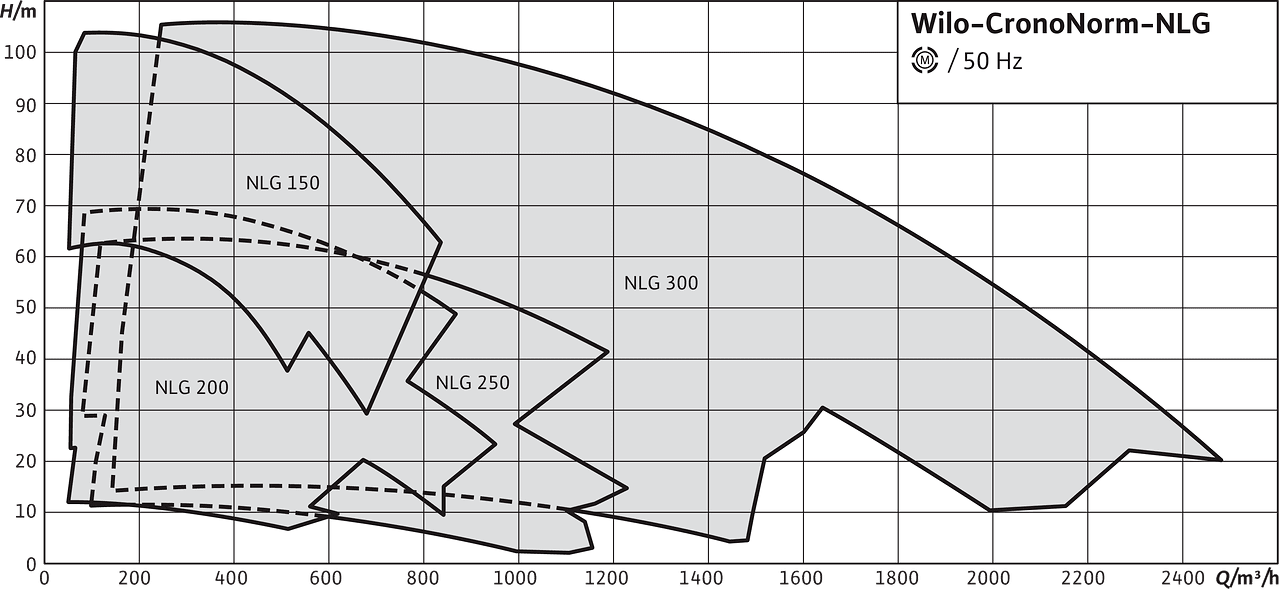

- Nominal diameter DN 150 to DN 300

- Max. operating pressure 16 bar

Materials

- Pump housing and pressure lid: EN-GJS-500-7

- Bearing bracket: EN-GJL-250

- Impeller: EN-GJL-250(special version: G-CuSn10)

- Shaft: 1.4028

- Stationary wear rings: G-CuSn10

- Mechanical seal: AQ1EGG;(other mechanical seals on request)

Construction

- Single-stage horizontal spiral housing pump with bearing bracket and exchangeable stationary wear rings in process design

- Shaft seal using mechanical shaft seals in accordance with EN 12756 or packing stuffing box

- Spiral housing with cast pump bases. Bearing of the pump shaft using greased grooved ball bearing

- Shaft coupling with intermediate sleeve

Scope of delivery

- Pump

- Installation and operating instructions

- Pump with free shaft end or

- Pump on baseplate with coupling and coupling guard or

- Completely mounted pump on baseplate with electric motor

Options

- Other materials and versions on request

- Other voltages and frequencies available on request.