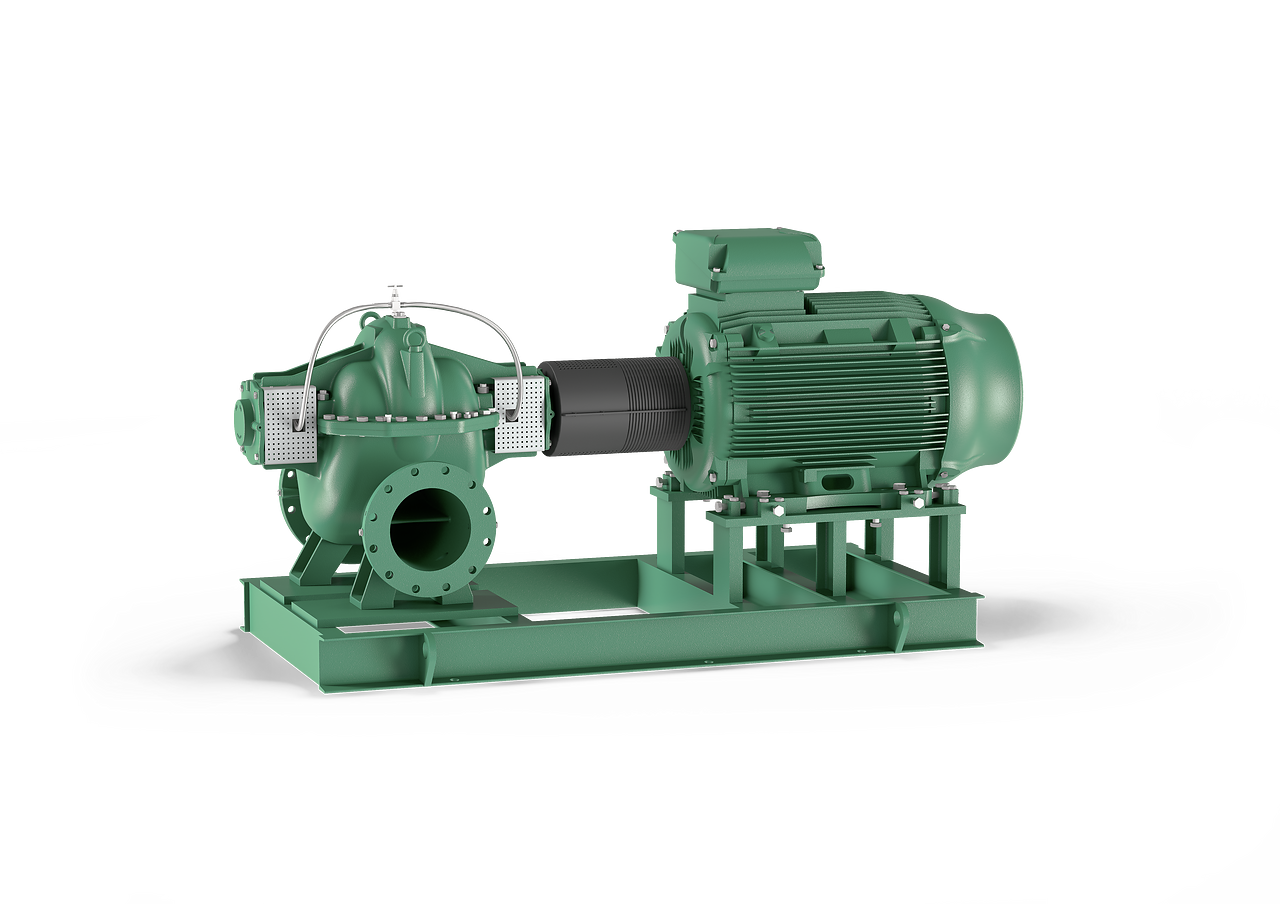

Wilo-Atmos TERA-SCH

Axially split case pump for reliable operation and energy-efficient transport of large volume flows through extensive distribution networks.

Wilo-Atmos TERA-SCH

Axially split case pump for reliable operation and energy-efficient transport of large volume flows through extensive distribution networks.

The Wilo-Atmos TERA-SCH axially split case pump provides a reliable water supply 365 days a year at low operating costs. The pump’s easy maintenance design and high efficiency across the entire characteristic curve ensure low-wearing and energy-efficient operation and contribute to the consistent water supply.

Recommended services

Your advantages

- Reliable continuous duty for an efficient drinking water supply over extensive piping networks – can be tailored to suit your exact requirements

- Reduced energy costs through high overall efficiency

- Simplified and shorter alignment process thanks to tolerant coupling and motor adjusting device

- Increased operational reliability thanks to quiet-running hydraulics with lower vibrations and reduced noise level

- Reduced cavitation tendency through optimised NPSH-performances

- Lower space requirements due to compact design

- Also available as certified drinking water version

- Optionally with Ceram CT coating – for an efficiency increase of up to 3 %

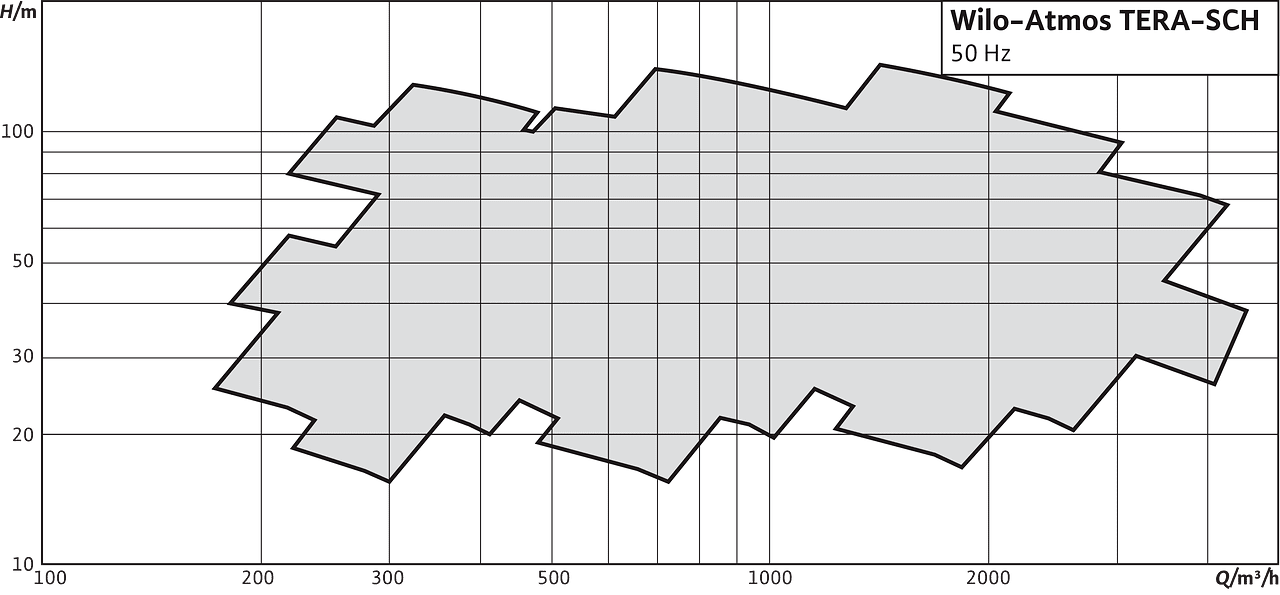

- Standard volume flow of up to 4500 m³/h

Wilo-Atmos TERA-SCH

Design type

Pump with axially split housing mounted on a base frame

Application

- Raw water intake, pressure boosting and general transport in power plants, waterworks and municipal drinking water supply networks

- Cooling water and industrial water supply in power plants and industrial facilities

- Irrigation in professional irrigation/agriculture

- Pumping of heating water (in accordance with VDI 2035 Germany) and water/glycol mixtures

Typekey

Example: | Atmos TERA-SCH 250/360-75/4-L1 |

Atmos | Product family |

TERA | Series |

SCH | Construction (splitcase pump, horizontal) |

250 | Nominal diameter DN of pressure port |

360 | Nominal diameter of the impeller in mm |

75 | Rated motor power P2 in kW |

4 | Number of poles |

L1 | Variant code (L1 = bronze impeller) |

Technical data

- Fluid temperature -20 °C to +120 °C

- Mains connection 3~400 V, 50 Hz

- Nominal diameters

- on the suction side: DN 150 to DN 600

- on the discharge side: DN 125 to DN 450

- Max. operating pressure: PN 10, PN 16

Materials

- Pump housing: EN-GJL-250

- Impeller: G-CuSn10

- Shaft: X12Cr13

Construction

- Centrifugal pump with axially split housing, available in single-stage design

- Delivered as complete unit (pump with coupling, coupling guard, motor and baseplate) or without motor or only pump hydraulics

- Shaft sealing with mechanical seal or stuffing box packing

- 2-, 4- and 6-pole motors; IE3-standard to 1000 kW (IE4 on request)

- Welded steel frame

Scope of delivery

- Bare shaft pump or with coupling or as complete unit

- Installation and operating instructions