Wilo-Sub TWU 3 Plug & Pump

Your advantages

- Easy installation due to preinstalled and pre-wired components

- Parts that come in contact with fluids are corrosion-free

- Integrated non-return valve

Design

Water-supply unit with submersible pump, control and complete accessories

Application

For pumping rainwater and industrial water from boreholes and wells for sprinkling, irrigation and water supply.

Equipment/function

Wilo-Plug & Pump package Sub-I (1/FC)

- Integrated non-return valve

- On/off switch

- Thermal motor protection

- Wilo-HiControl 1 for automatic flow and pressure monitoring with integrated dry-running protection

Wilo-Plug & Pump package Sub-II (2/PS)

- Integrated non-return valve

- On/off switch

- Thermal motor protection

- Wilo pressure switching 0 – 10 bar, including 18 l diaphragm expansion tank, manometer, shut-off device and pressure switch for automatic control

Typekey

Example: | Wilo-Sub TWU 3-0115-EM-PnP/FC |

TWU | Series |

3 | Diameter of the hydraulic unit in inches ["] |

01 | Rated volume flow [m3/h] |

15 | Number of hydraulic stages |

EM | Mains connection:

|

PnP | Plug & Pump water supply system |

FC | Version

|

Technical data

- Mains connection: 1~230 V, 50 Hz or 3~400 V, 50 Hz

- Submerged operating mode: S1

- Fluid temperature: 3 ... 35 °C

- Minimum flow rate at motor: 0.08 m/s

- Max. sand content: 50 g/m3

- Max. number of starts: 30/h

- Max. immersion depth: 27 m

- Protection class: IP58

- Discharge port: Rp1

Materials

- Hydraulics housing: 1.4301

- Impellers: Polycarbonate

- Hydraulic shaft: 1.4104

- Motor housing: 1.4301

- Motor shaft: 1.4305

Construction

Submersible pump for vertical or horizontal installation.

Hydraulics

Multistage submersible pump with radial impellers in sectional construction and integrated non-return valve. Discharge port with threaded flange and female thread. All parts that come in contact with the fluid are made of corrosion-free materials.

Motor

Single-phase or three-phase current motor for direct starting. The oil-filled motor is rewindable and has self-lubricating motor bearings.

Cooling

- The motor is cooled by the pumped fluid. Always operate the pump in a submerged state.

- Vertical installation is possible with or without cooling jacket.

- Horizontal installation must be performed in conjunction with a cooling jacket.

Scope of delivery

Wilo-Plug & Pump package Sub-I (1/FC)

- Motor and hydraulics fully assembled

- 30 m connection cable

- Switch box with capacitor

- Wilo-HiControl 1

- 30 m guy rope

- Installation and operating instructions

Wilo-Plug & Pump package Sub-II (2/PS)

- Motor and hydraulics fully assembled

- 30 m connection cable

- Switch box with capacitor

- 18 l diaphragm expansion tank

- Pressure gauge

- Shut-off device

- Pressure switch

- 30 m guy rope

- Installation and operating instructions

Accessories

- Cooling shrouds

- Connection and installation material

Installation and operating instructions

Group Statement

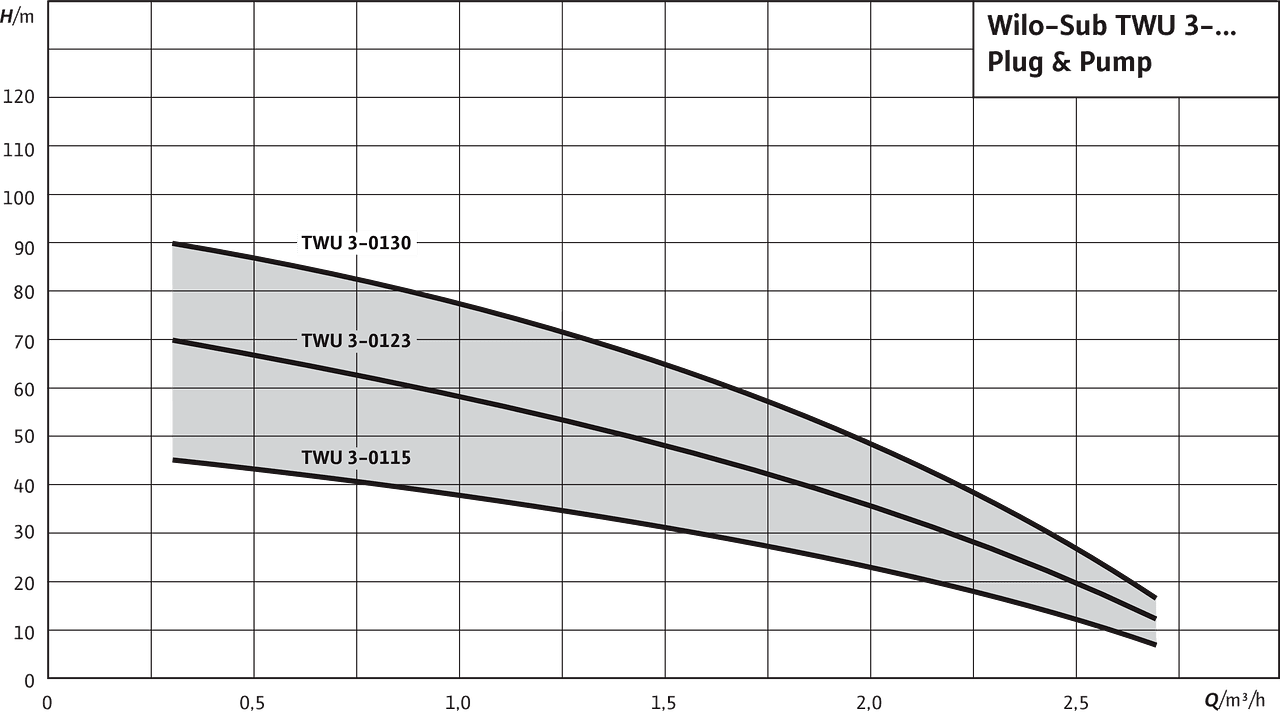

| Product description | Mains connection | Motor diameter Ø | Number of stages | Rated power P2 | Connection | Article number | |

|---|---|---|---|---|---|---|---|

Sub TWU 3 0115 EM-PnP(2/PS) | 1~230 V, 50 Hz | 3 in (") | 15 | 0.37 kW | Rp 1 | 4091654 | |

Sub TWU 3-0115-EM-PnP(1/FC) | 1~230 V, 50 Hz | 3 in (") | 15 | 0.37 kW | Rp 1 | 4091647 | |

Sub TWU 3-0123-EM-PnP(1/FC) | 1~230 V, 50 Hz | 3 in (") | 23 | 0.55 kW | Rp 1 | 4091649 | |

Sub TWU 3-0123-EM-PnP(2/PS) | 1~230 V, 50 Hz | 3 in (") | 23 | 0.55 kW | Rp 1 | 4091655 | |

Sub TWU 3-0130-EM-PnP(1/FC) | 1~230 V, 50 Hz | 3 in (") | 30 | 0.75 kW | Rp 1 | 4091650 | |

Sub TWU 3-0130-EM-PnP(2/PS) | 1~230 V, 50 Hz | 3 in (") | 30 | 0.75 kW | Rp 1 | 4091656 |