Wilo-Stratos GIGA-D

Maximum energy efficiency, double safety.

Maximum energy efficiency, double safety.

The Wilo-Stratos GIGA is the ideal high-efficiency pump for use in heating, air conditioning and cooling applications in buildings where large volumes of water have to be pumped to great delivery heights. Wilo-Stratos GIGA offers ever greater operational reliability with the standby pump in the twin-head pump version.

Recommended services

Your advantages

- Innovative high-efficiency pump for maximum overall efficiency levels

- High-efficiency EC motor with efficiency class IE5 according to IEC 60034-30-2

- Highest possible operational reliability thanks to standby pump

- Optional interfaces for connection to building automation using insertable IF modules

Design

High-efficiency in-line twin-head pump with EC motor and electronic power adjustment in glanded pump construction. Version as single-stage low-pressure centrifugal pump with flange connection and mechanical seal.

Application

Pumping of heating water (acc. to VDI 2035), chilled water and water/glycol mixtures without abrasive substances in heating, chilled water and cooling systems.

Equipment/function

Operating modes

- Δp-c for constant differential pressure

- Δp-v for variable differential pressure

- PID control

- Constant speed (n=constant)

Manual operation level

- Green button and display

Manual functions

- Differential pressure setpoint setting

- Setting the speed (manual control mode)

- Setting the operating mode

- Setting the pump ON/OFF

- Configuration of all operating parameters

- Fault acknowledgement

External control functions

- "Overriding Off" control input

- “External pump cycling” control input (effective only in dual pump operation)

- Analogue input 0 – 10 V, 0 – 20 mA for constant speed (DDC) and remote setpoint adjustment

- Analogue input 2 – 10 V, 4 – 20 mA for constant speed (DDC) and remote setpoint adjustment

- Analogue input 0 – 10 V for actual value signal from pressure sensor

- Analogue input 2 – 10 V, 0 – 20 mA, 4 – 20 mA for actual value signal from pressure sensor

Signal and display functions

- Collective fault signal SSM

- Collective run signal SBM

Data exchange

- Infrared interface for wireless data exchange with IR-Monitor/IR-Stick

- Plug-in position for Wilo IF-Modules (Modbus, BACnet, CAN, PLR, LON) for connection to building automation

Safety functions

- Full motor protection with integrated trip electronics

- Access disable

Dual pump management (double pump or 2 x single pumps)

- Main/standby operation (automatic fault-actuated switchover)

- Pump cycling main/standby operation after 24 hours

- Parallel operation

- Parallel operation (efficiency-optimised peak-load activation and deactivation)

Typekey

Example | Wilo-Stratos GIGA D 40/1-51/4.5 |

Stratos GIGA | High-efficiency pump |

D | In-line double pump |

40 | Nominal flange diameter DN |

1-51 | 1 = lowest selectable delivery head [m] 51 = highest selectable delivery head [m] |

4.5 | Orientation value of the rated power P2 in [kW] |

-xx | Version: E.g. R1 - version without differential pressure sensor |

Technical data

- Permitted temperature range of the fluid: -20 °C to +140 °C

- Mains connection 3~480 V ±10 %, 50/60 Hz, 3~440 V ±10 %, 50/60 Hz, 3~400 V ±10 %, 50/60 Hz, 3~380 V -5 % +10 %, 50/60 Hz

Compliance with electromagnetic compatibility without additional measures:

- Interference emission for residential environment according to EN 61800-3:2018

- Interference immunity for industrial environments according to EN 61800-3:2018

- Protection class IP55

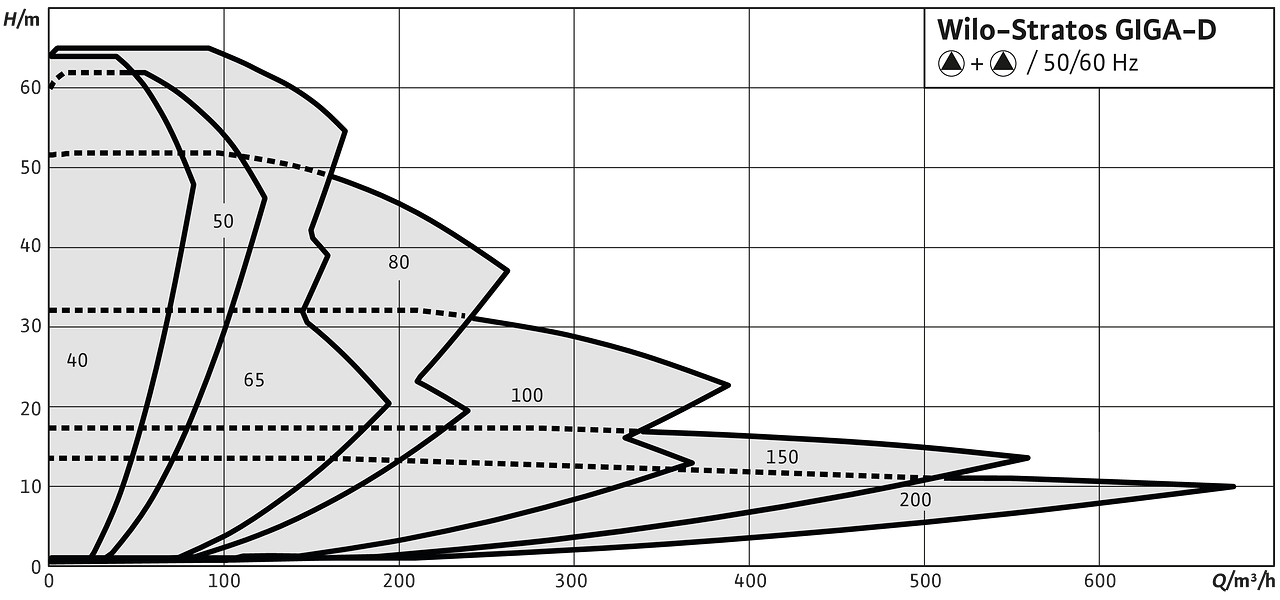

- Nominal diameter DN 40 to DN 200

- Max. operating pressure 16 bar up to +120 °C, 13 bar up to +140 °C

Materials

- Pump housing and lantern: EN-GJL-250

- Impeller: PPS-GF40

- Shaft: 1.4122

- Mechanical seal: AQEGG; other mechanical seals on request

Scope of delivery

- Pump

- Installation and operating instructions

Options

- Variant …-R1 without differential pressure sensor

- …-S1 variant with special mechanical seal

Accessories

- 3 mounting brackets with fixation material for installation on a base

- Blind flanges for twin-head pump housing

- Installation aid for mechanical seal

- IR-Stick

- IF module PLR for connecting to PLR/interface converter

- IF module LON for connection to the LONWORKS network

- IF module BACnet

- IF module Modbus

- IF module CAN

- Control system VR-HVAC

- Control system CCe-HVAC

- Control system SCe-HVAC

- Differential pressure sensor (DDG)

Installation and operating instructions

Wilo-Stratos GIGA, Wilo-Stratos GIGA-D, Wilo Stratos GIGA B

| Article Number | 2160202 |

| Edition | 2022-08 |

| Number of pages | 268 |

| Language | de, en, fr, nl |

Wilo-Stratos GIGA, Wilo-Stratos GIGA-D, Wilo-Stratos GIGA B

| Article Number | 2234261 |

| Edition | 2024-02 |

| Number of pages | 336 |

| Language | de, en, fr, nl |

Wilo-Stratos GIGA, Wilo-Stratos GIGA-D, Wilo-Stratos GIGA B

| Article Number | 2234260 |

| Edition | 2024-02 |

| Number of pages | 88 |

| Language | en |

Consulting manual

Glanded pumps, single-stage, single-volute

| Article Number | Wilo515021 |

| Edition | 2021-12 |

| Number of pages | 24 |

| Language | en |

Certification booklet

Wilo-Stratos GIGA2.0-I/-D, Wilo-Stratos GIGA /-D/-B, Wilo-Yonos GIGA2.0-I/-D

| Article Number | 2216678 |

| Edition | 2022-11 |

| Number of pages | 52 |

| Language | language neutral |