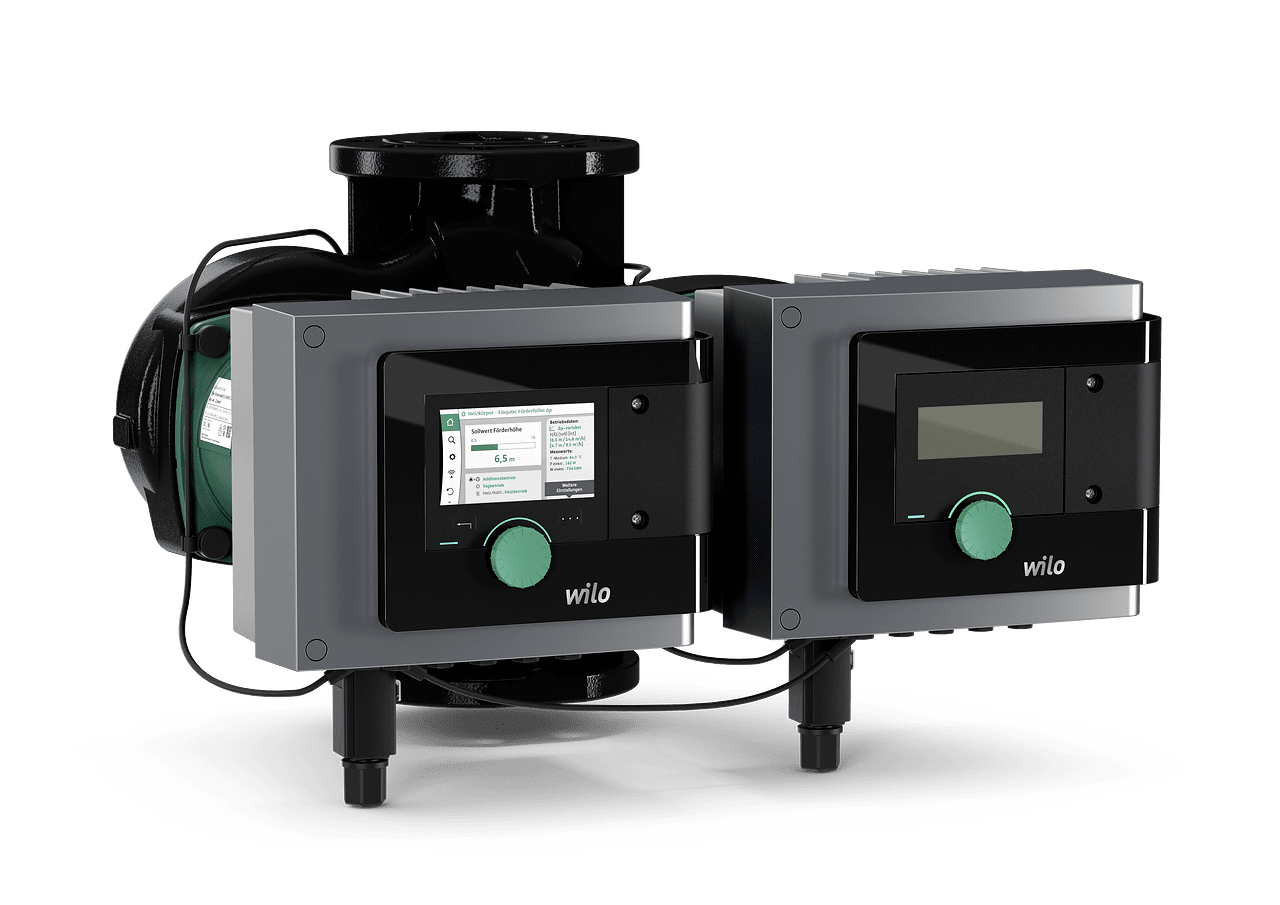

Wilo-Stratos MAXO-D

The smart-pump for commercial buildings with building management system.

The smart-pump for commercial buildings with building management system.

With optimised and innovative energy-saving features, the Wilo-Stratos MAXO sets new standards for commercial HVAC applications in terms of energy efficiency. Its outstanding user-friendliness makes operating the pump easier than ever before.

Recommended services

Your advantages

- Intuitive operation by application-guided settings with the Setup Guide plus the combination of a new display and operating button using the Green Button Technology

- Maximum energy efficiency thanks to the combination of optimised and innovative energy-saving functions (e.g. No-Flow Stop)

- Optimum system efficiency thanks to new and innovative intelligent control functions, such as Dynamic Adapt plus, Multi-Flow Adaptation, T-const. and ΔT-const.

- Latest communication interfaces (e.g. Bluetooth) for connecting to mobile terminal devices and direct pump networking using Wilo Net for multiple pump control

- Maximum convenience in electrical installation thanks to a clearly arranged and spacious terminal box and the optimised Wilo-Connector

Eco-friendly features

- Combination of optimised and innovative control modes provides maximum energy efficiency

- Highest system efficiency with the innovative “Multi-Flow Adaptation” and energy savings of up to 80%

- Sustainable and carbon-neutral production and processes in our European factories

- Full transparency of the pump's operating status via remote access to save resources compared to on-site assessments

Design type

Smart glandless twin-head circulator with screwed connection or flange connection, EC motor with integrated electronic power adjustment.

Application

Hot-water heating systems of all kinds, air-conditioning systems, closed cooling circuits, industrial circulation systems.

Equipment/function

Field of application

The pump facilitates an operation with highest system efficiency via precise setting of the control mode for the system-specific application (e.g. radiator, underfloor heating, ceiling cooling).

Heating

- Radiator

- Underfloor heating

- Ceiling heating

- Fan heater

- Concrete core heating*

- Hydraulic shunt

- Differential pressure-less distributor*

- Buffer heating*

- Heat exchanger

- Heat source circuit (heat pump)*

- District heating loop*

Cooling

- Ceiling cooling

- Underfloor cooling

- Air-conditioning devices

- Concrete core cooling*

- Hydraulic shunt

- Differential pressure-less distributor*

- Buffer cooling*

- Heat exchanger

- Recooling circuit*

- District cooling circuit*

(* system types from SW≥01.05.10.00 available)

Heating and cooling combined

- Automatic switchover (version “-R7”: not possible; however, possible with Stratos MAXO temperature sensor)

The following control modes are available depending on the selected application:

Control modes

- Constant speed (control mode)

- Δp-c for constant differential pressure

- Δp-v for variable differential pressure

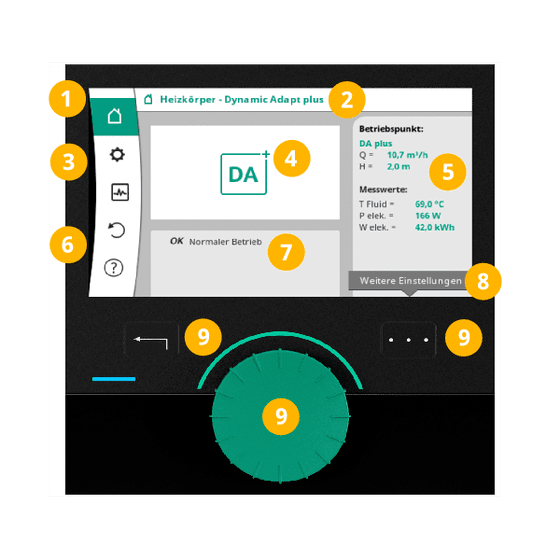

- Dynamic Adapt plus for continuous (dynamic) adjustment of the delivery rate to the current requirement

- T-const. for constant temperature control

- ΔT-const. for constant differential temperature control

- Constant Q for constant volume flow control

- Multi-Flow Adaptation: Total volume flow determination through the feeder pump for the needs-based supply of secondary pumps in the heating circuit distributors

- User-defined PID control

Optional functions

- Q-Limitmax. for limiting the maximum volume flow

- Q-Limitmin. for limiting the minimum volume flow

- No-Flow Stop (zero-flow-deactivation)

- Automatic night setback (version “-R7”: not possible; however, possible with Stratos MAXO temperature sensor

- Index circuit evaluator (Δp-c control with external actual value sensor)

- Thermal disinfection detection (Stratos MAXO-Z)

- Variable pitch of Δp-v pump curve

Manual settings

- Selection of the field of application in the setting assistant

- Setting the related operating parameters

- Nominal duty point: direct input of calculated duty point at Δp-v

- Status display

- Setting and resetting the energy meters (heating and cooling)

- Pump venting function

- Key lock for disabling the settings

- Function for resetting the factory settings or the saved restoration points (parameter sets)

- Parameterising the analogue inputs

- Parameterising the binary inputs

- Parameterising the relay outputs

- Dual-pump function (for 2 single pumps, which should be operated as a two-pump system)

Automatic functions

- Power adjustment according to requirements for energy-efficient operation depending on the operating mode

- Detection of night setback (version “-R7”: not possible; however, possible with Stratos MAXO temperature sensor

- Deactivation at zero flow (No-Flow Stop)

- Soft start

- Automatic troubleshooting routines (e.g. deblocking function)

- Switchover between heating/cooling mode (version "-R7": automatic switchover not possible; however, possible with Stratos MAXO temperature sensor)

- Full motor protection with integrated trip electronics

External control inputs and their functions

2 x analogue inputs:

- Signal types: 0 – 10 V, 2 – 10 V, 0 – 20 mA, 4 – 20 mA, PT1000

- Applications: Remote adjustment of the setpoints in every control mode (except Multi-Flow Adaptation), sensor inputs for temperature, differential pressure or free sensor in user-defined PID operation

2 x digital inputs:

- For potential-free control outputs or switch

- Parametrisable functions:

- Ext. Off

- Ext. Min

- Ext. Max

- MANUAL (BMS-OFF)

- Key lock

- Switchover between heating/cooling mode

Wilo Net for dual-pump management of 2 single pumps, communication of several pumps with each other and pump remote adjustment via gateway

Signal and display functions

- Display status operation display:

- Setpoint

- Actual delivery head

- Actual volume flow

- Power consumption

- Electric consumption

- Temperatures (version "-R7": current fluid temperature possible with Stratos MAXO temperature sensor)

- Status display LED: Faultless operation (green LED), pump communication (blue LED)

- Display status of display fault (display red):

- Error codes and error description in full text

- Remedial measures

- Display status of display warning (display yellow):

- Warning codes and description of the warning in full text

- Remedial measures

- Display status process indicator (display blue):

- Pump venting

- Update procedure

- Display BMS communication (display blue):

- Summary of the active BMS parameters (baud rate, address...)

- Collective fault signal SSM (potential-free changeover contact)

- Collective run signal SBM (potential-free normally open contact)

Data exchange

- Bluetooth interface for wireless data exchange and remote operation of the pump using a smartphone or tablet.

- Remote monitoring of the pump via WiloCare.

- Digital Modbus TCP interface for connection to building automation (BA) (possible with Wilo-CIF module Ethernet [multi-protocol]).

- Serial digital interface Modbus RTU for connecting building automation (BA) via RS485 bus system (possible with Wilo-CIF module Modbus RTU).

- Digital BACnet IP interface for connection to building automation (BA) (possible with Wilo-CIF module Ethernet).

- Serial digital interface BACnet MS/TP for connecting building automation (BA) via RS485 bus system (possible with Wilo-CIF module BACnet MS/TP).

- Serial digital interface LON for connecting building automation (BA) via bus system LONWorks (possible with Wilo-CIF module LON).

- Serial digital interface CANopen for connecting building automation (BA) via bus system CANopen (possible with Wilo-CIF module CANopen).

- Serial digital interface PLR for connecting BA via company-specific coupling module (possible with Wilo-CIF module PLR).

Dual-pump management (twin-head pump or 2 x single pumps)

- Main/standby operation (automatic fault-actuated switchover/time-sensitive pump alteration)

- Parallel operation (efficiency-optimised peak load cut-in and out)

Equipment

- For flange-end pumps: Flange versions

- Standard version for DN 32 to DN 65 pumps: PN 6/10 combination flange (PN 16 flange according to EN 1092-2) for PN 6 and PN 16 counter flanges

- Standard version for DN 80/DN 100 pumps: PN 6 flange (designed for PN 16 according to EN 1092-2) for PN 6 counter flange

- Special version for DN 32 to DN 100 pumps: PN 16 flange (according to EN 1092-2) for PN 16 counter flange

- Various integrated communication interfaces and optionally usable CIF module plug-in position

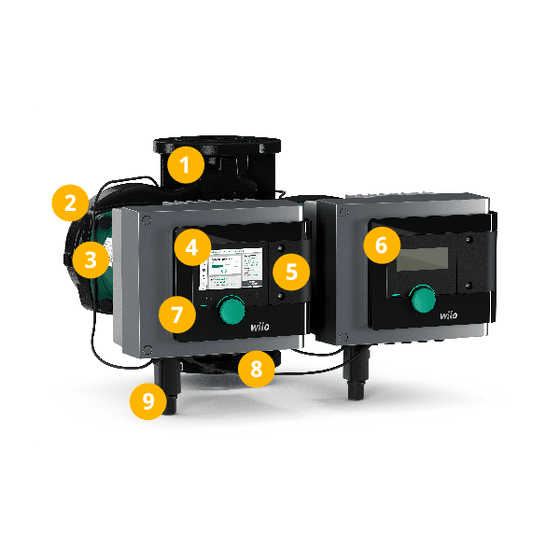

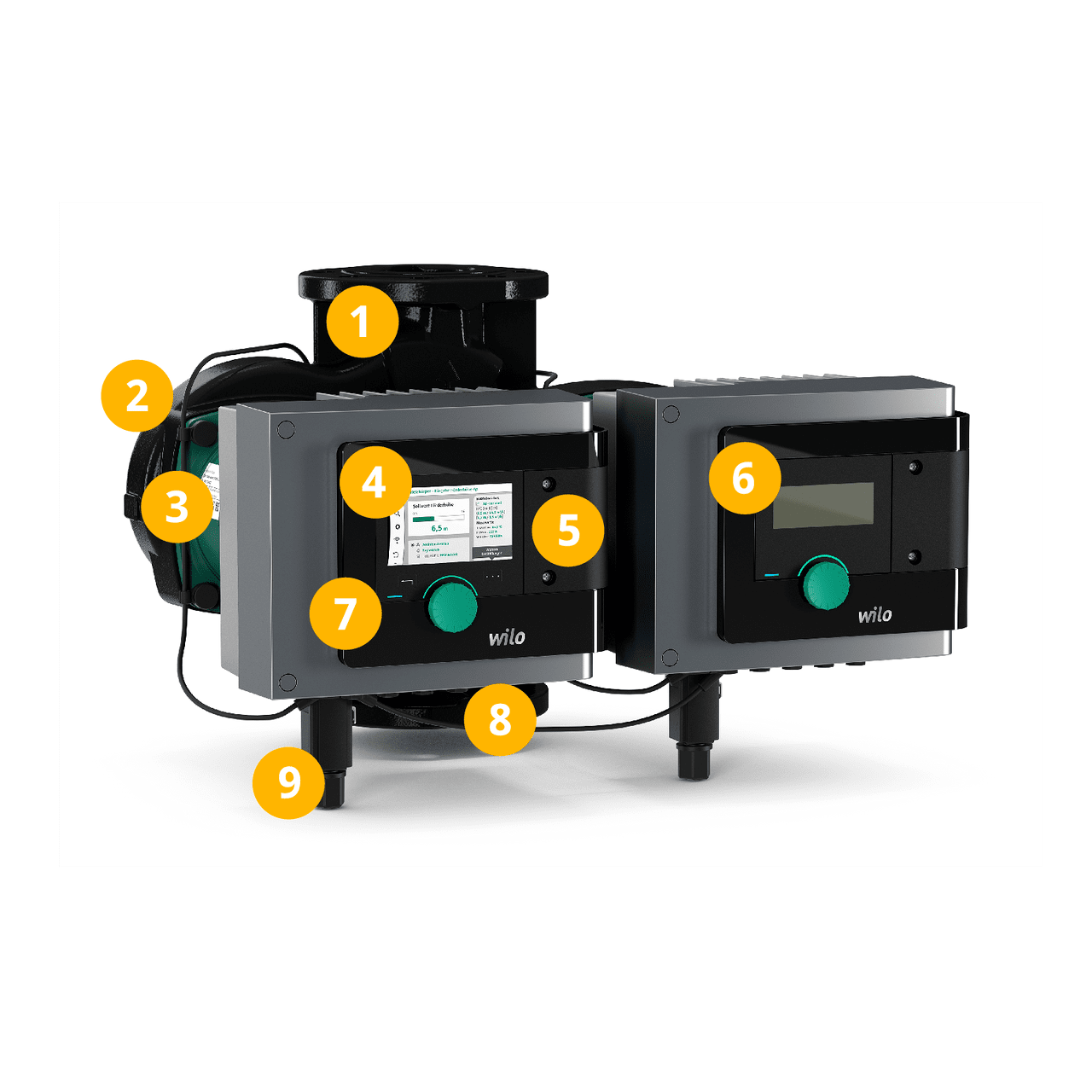

- 5 cable inlets for connecting the communication interfaces

- Bluetooth interface

- High resolution graphic display with green button and 2 additional buttons

- User-friendly terminal room

- Integrated temperature sensor (version "-R7": without)

- Quick electrical connection with optimised Wilo-Connector for the power supply

Scope of delivery

- Pump

- 2x optimised Wilo-Connector

- 4x threaded cable gland M16 x 1.5

- Gaskets for threaded connection

- Washers for flange screws (for nominal connection diameters DN 32 - DN 65)

Typekey

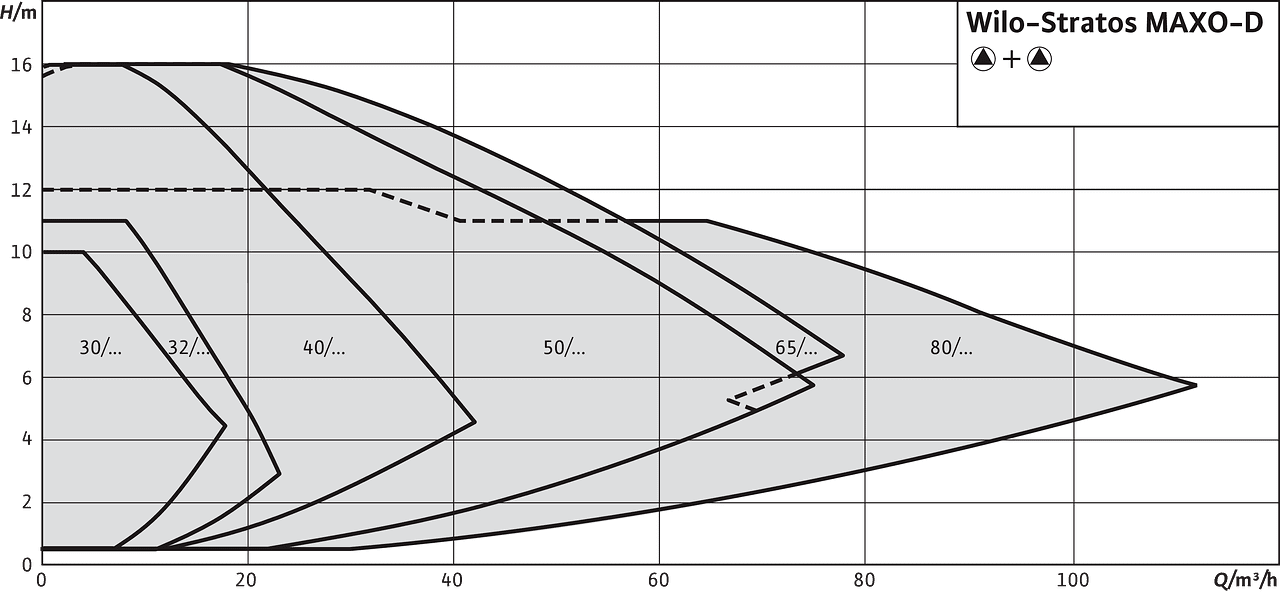

Example: | Wilo-Stratos MAXO-D 40/0,5-8 |

Stratos MAXO | High-efficiency pump (flange-end pump), electronically controlled |

D | Twin-head pump |

40/ | Nominal connection diameter |

0.5-8 | Nominal delivery head range [m] |

-R7 | Without an integrated Stratos MAXO temperature sensor |

Technical data

- Permissible temperature range -10 °C to +110 °C, -10 °C to +90 °C

- Mains connection 1~230 V, 50/60 Hz

- IP rating IPX4D

- Screwed connection DN 30 (RP 11/4)

- Flange connection DN 32 to DN 80

- Max. operating pressure of standard version: 6/10 bar or 6 bar (special version: 10 bar or 16 bar)

- Insulation class: F

- Interference emission in acc. with: EN 61800-3:2004+A1:2012/residential environment (C1)

- Interference immunity in acc. with: EN 61800-3:2004+A1:2012 / industrial environment (C2)

- Max. volume flow Q: 112 m³/h

- Max. delivery head H: 16 m

Materials

- Bearing : Carbon-graphite

- Impeller : PPS-GF40

- Pump housing : Grey cast iron

- Shaft : 1.4028, DLC-coated

Construction

- Smart glandless twin-head circulator with EC motor and integrated electronic power adjustment

- Green Button Technology and graphic display

- Motor protection with trip electronics

- Plug connection for functional extension with optional CIF-modules for building automation (BA)

- Impeller with three-dimensionally curved blades and plastic sealing tube made of carbon fibre composite material