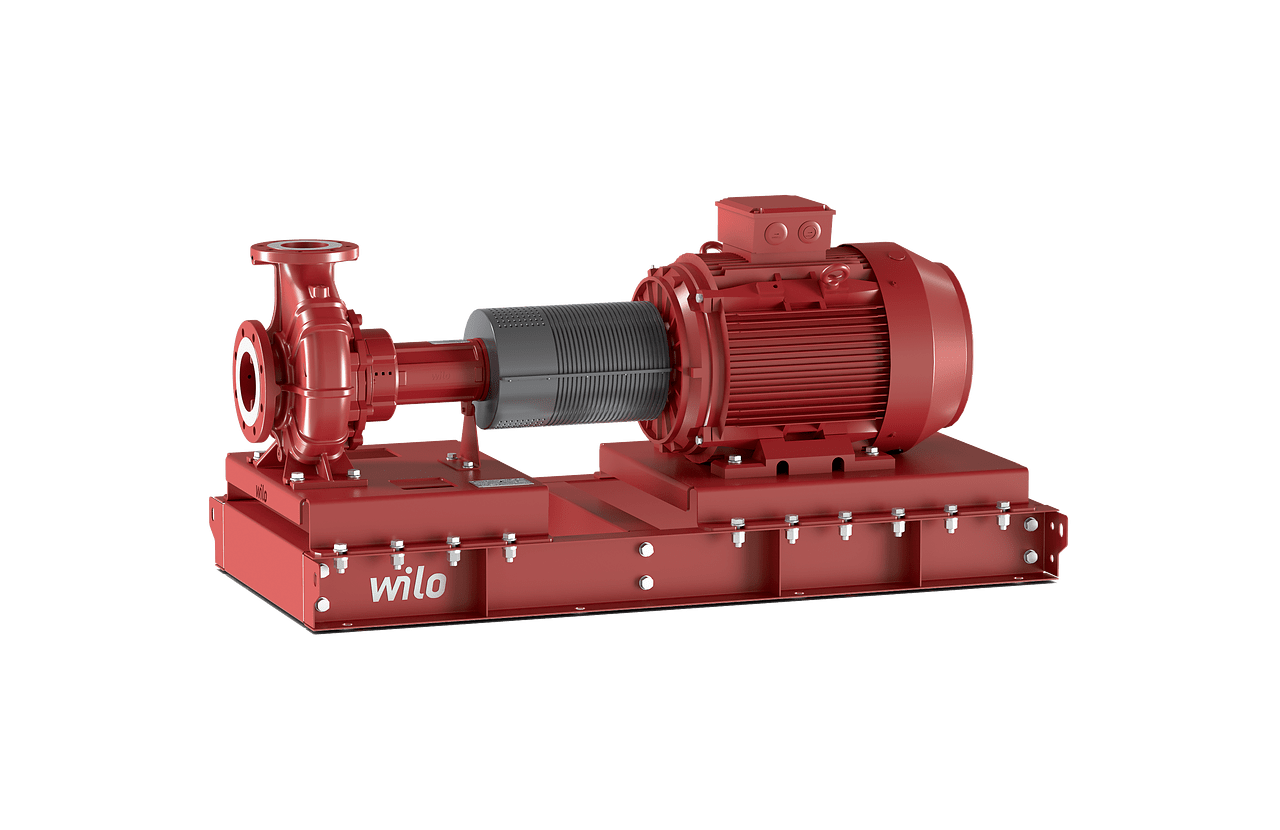

Wilo-Atmos GIGA-NF

The norm pump for automatic firefighting applications.

The norm pump for automatic firefighting applications.

The Wilo-Atmos GIGA-NF norm pump offers high reliability and long service life as an entry level model for automatic firefighting thanks to its corrosion-resistant components. The user-friendly “back pull-out” design also simplifies maintenance. The Wilo-Atmos GIGA-NF offers high operational reliability. It is VDS tested and protected against overheating in case of application. Their modular design also allows them to be equipped with both diesel and electric motors. The diesel version has a large reservoir that allows firefighting for up to six hours. The pump is mounted on a base frame, making it very easy and safe to transport, install and maintain.

Your advantages

- High reliability and durability thanks to cataphoretic coating of all cast components, bronze impeller and stainless steel slip rings for high corrosion resistance

- User-friendly “back pull-out” design for easy maintenance

- Different drives depending on individual requirements

- Valve at pump outlet ensures minimum water flow to protect against overheating

- Easy and safe transport, installation and maintenance thanks to solid construction on base frame

Design type

Single-stage, horizontal centrifugal pump for firefighting water supply according to EN 733 and VdS 2100-07 for installation on a base frame.

Depending on the version, consisting of one pump mounted on base frame with spacer coupling or universal joint and electric or diesel motor.

Application

Automatic water supply for fire-extinguishing systems with sprinklers in domestic, commercial and administration buildings, hotels, hospitals, shopping centres, office blocks and industrial buildings.

Equipment/function

- One horizontal baseplate pump according to VdS 2100-07 with IE4-equivalent standard motor or diesel motor.

- Base frame made of epoxy-coated steel.

Typekey

Example: | Atmos GIGA-NF 80/200-224-45/2-L1-N37 |

Atmos GIGA | Product name |

NF 80/200 | Pump type |

224 | Impeller diameter [mm] |

45 | Drive power [kW] * |

2 | Electric motor: Number of poles |

L1 | Wilo code for bronze impeller |

N37 | Wilo code for VdS approval |

* = minimum motor power, do not fall below. |

Technical data

- Mains connection: 3~400 V, 50 Hz (12 VDC for starter for diesel pumps)

- Max. fluid temperature: +25 °C

- Min./max. ambient temperature: +4 ... +40 °C (+10 ... +40 °C for pumps with diesel motor)

- Max. operating pressure: 12 bar

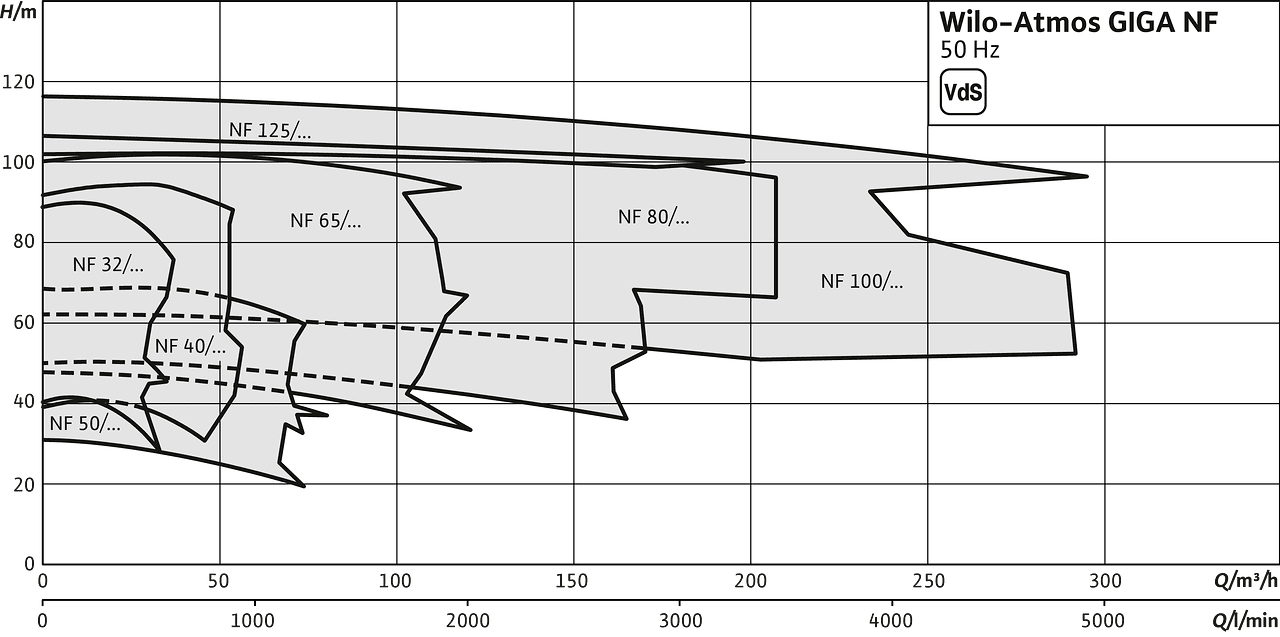

- Max. volume flow: 10 ... 295 m3/h

- Max. delivery head: 105 m

Electrical IEC standard motor:

- Efficiency class: <75 kW: IE3, 75 ... 200 kW: IE4

- Max. power: 200 kW

- Rated speed: 2940 rpm

- IP rating: IP55

Diesel motor:

- Direct injection or charged diesel motor with air or water cooling

- Max. power: 197 kW

- Lubrication: Forced lubrication with gear pump and oil filter

- Cooling according to power: Up to 17.7 kW with air flow. From 26.5 kW with water/water heat exchanger.

Other:

- Nominal connection diameters on the discharge side: DN 32 up to DN 125, according to EN 1092, PN 16

- Nominal connection diameters on the suction side: DN 50 up to DN 150, according to EN 1092, PN 16

Materials

- Impeller made of bronze CuSn10 or CuAl10Fe5Ni5

- Neck ring made of stainless steel AISI316L/1.4409

- Pump housing made of cast iron EN-GJL-250

- Shaft made of stainless steel AISI420/1.4021

Construction

- Centrifugal pump in back pull-out design according to EN 733 and VdS 2100-07 with axial suction connection and radial discharge connection for installation on a base frame. All cast iron components in contact with the fluid are cataphoretic coated as standard. Shaft sealing with bidirectional bellows mechanical seal. Pump with pump support foot and flanged bearing bracket.

- Bypass valve installed directly on the pump housing.

- Spacer coupling for electric motor or cardan joint for diesel motor.

- IE4 electric motor or direct-injected or supercharged diesel motor with air or water cooling.

- Base frame made of special steel profiles with pre-assembled eyelets for lifting gear.

Scope of delivery

- Factory assembled pump in transport packaging

- Installation and user manual

- Required accessories on request