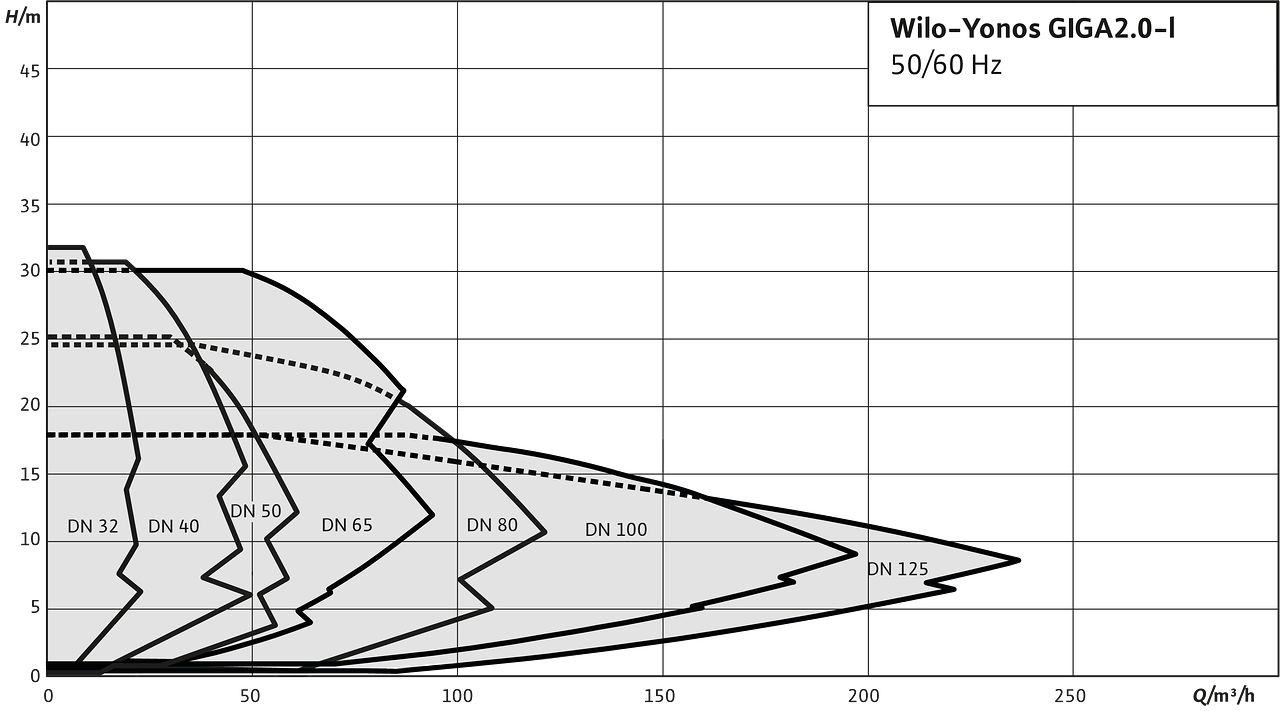

Wilo-Yonos GIGA2.0-I

Efficient pumping of large amounts of water for heating, air-conditioning and cooling applications in large buildings.

Efficient pumping of large amounts of water for heating, air-conditioning and cooling applications in large buildings.

The Wilo-Yonos GIGA2.0-I is an electronically controlled in-line glanded pump, which is suitable for pumping large amounts of water over large delivery heads. Thanks to IE5 EC motor technology and proven pump hydraulics (MEI ≥0.4), it provides both high energy efficiency and a high level of reliability. It is very easy to use thanks to the established Green Button Technology, user-friendly menu navigation and clear colour display. Analogue and digital interfaces provide the option of integration into building automation systems.

Recommended services

Your advantages

- High energy efficiency thanks to IE5 EC motor technology and proven pump hydraulics (MEI ≥0.4)

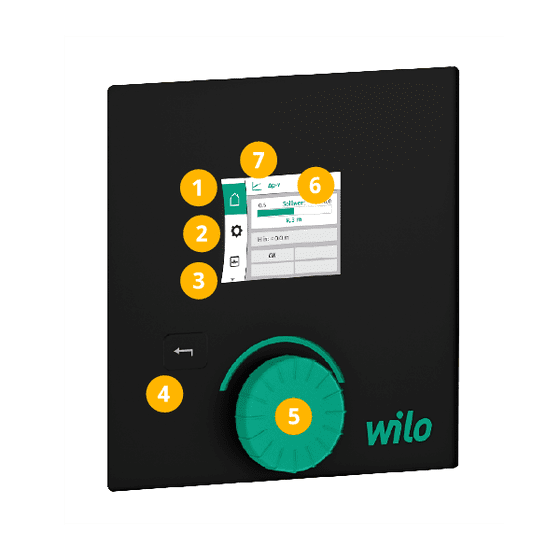

- Easy to use with clear menu navigation, colour display and Green Button Technology

- High reliability thanks to innovative drive technology and proven pump hydraulics

- Ready for integration into building automation systems via analogue and digital interface and CIF module

Eco-friendly features

- High-efficiency pump with IE5 motor technology according to IEC 60034-30-2 and MEI ≥ 0.4

- Sustainable and carbon-neutral production and processes in our European factories

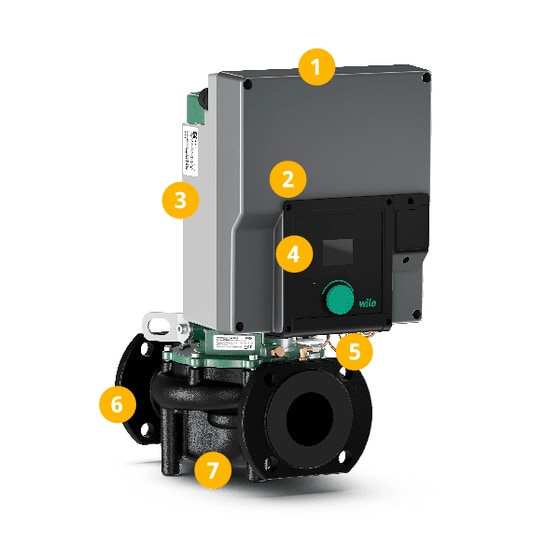

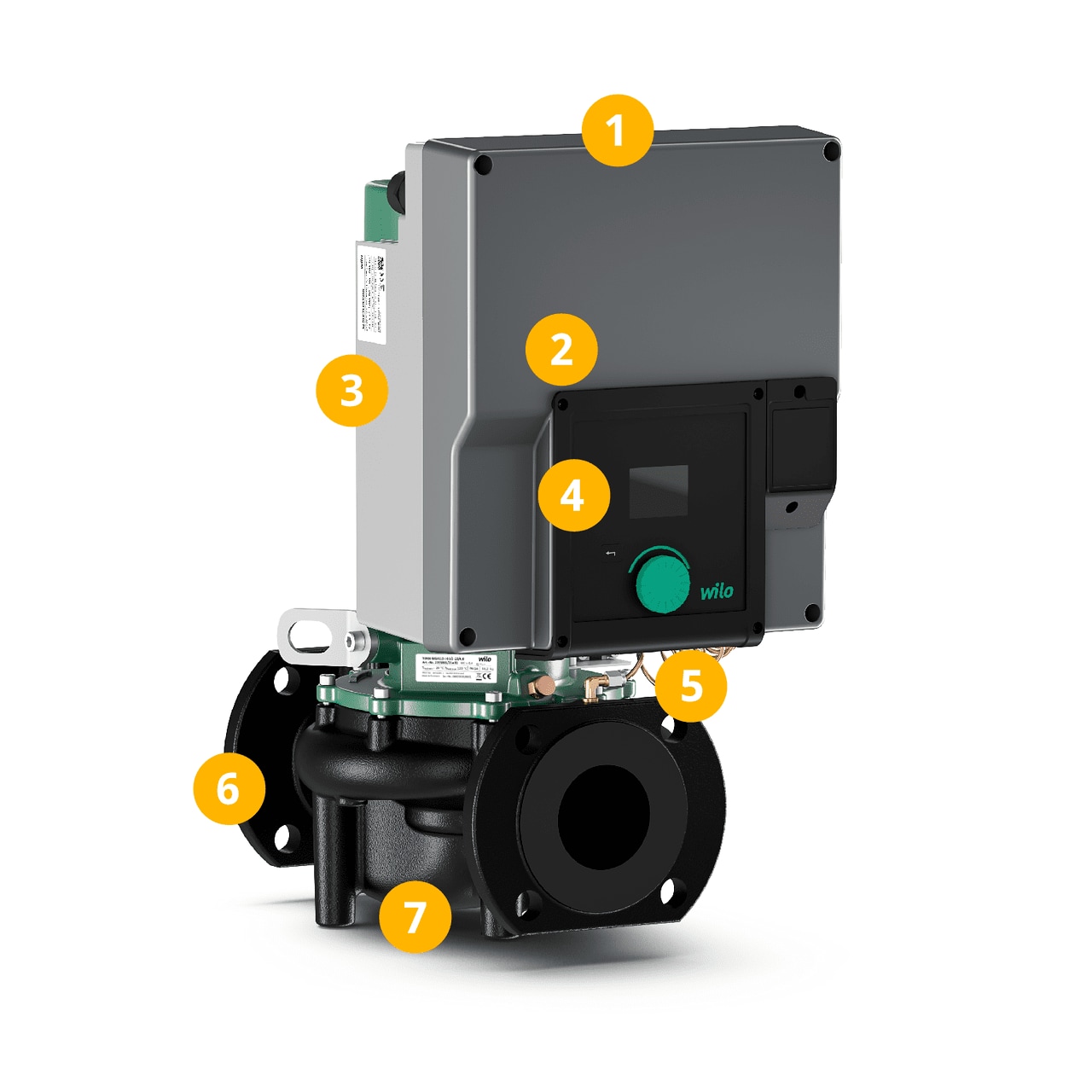

Design

In-line pump with high efficiency with IE5 motor and electronic power adjustment in glanded pump design. Version as single-stage low-pressure centrifugal pump with flange connection and mechanical seal.

Application

The pumping of heating water (in accordance with VDI 2035), chilled water and water-glycol mixtures without abrasive substances in heating, chilled water and cooling systems.

Equipment/function

Control modes:

- Δp-v for variable differential pressure

- Δp-c for constant differential pressure

- Constant speed

- User-defined PID control

Manual settings:

- Setting the control mode

- Setting the related operating parameters

- Parameterising the analogue inputs

- Parameterising the digital input

- Parameterising the relay outputs

- Twin-head pump function (for 2 single pumps, which should be operated as twin-head pump)

- Key lock for disabling the settings

- Function for resetting to factory setting

Automatic functions:

- Power adjustment according to requirements for energy-efficient operation depending on the control mode

- Automatic troubleshooting routines

- Integrated full motor protection

External control inputs and outputs and their functions

- 1 x analogue input:

- Signal types: 0 ... 10 V, 2 ... 10 V, 0 ... 20 mA, 4 ... 20 mA

- Application: only sensor value from differential pressure sensor (installed serially on the pump as standard)

- 1 x analogue input:

- Signal types: 0 ... 10 V, 2 ... 10 V, 0 ... 20 mA, 4 ... 20 mA

- Application: only external setpoint sensor

- 1 x digital input:

- Control input for “External OFF” function

- 2x relay output:

- Collective fault signal SSM (potential-free changeover contact)

- Collective run signal SBM (potential-free changeover contact)

- Wilo Net

- For dual pump management of 2 single pumps

Signal and display functions

- Display status of "Operation display":

- Current control mode

- Setpoint

- Actual delivery head

- Actual speed

- Actual volume flow

- Electrical power consumption

- Status display LED: Faultless operation (green LED), pump communication (blue LED)

- Display status of "Display fault" (display red):

- Error codes

- Display status of "Display warning" (display yellow):

- Warning codes

- Display status of "Process indicator" (display blue):

- Display status of "Building automation (BA) communication" (display blue):

- Summary of the active building automation (BA) parameters (baud rate, address, etc.)

- Collective fault signal SSM (potential-free changeover contact)

- Collective run signal SBM (potential-free changeover contact)

Data exchange

- Possible with accessories of corresponding WILO-CIF modules:

- Serial digital Modbus RTU interface for connection to building automation (BA) via RS485 bus system

- Serial digital BACnet MS/TP interface for connection to building automation (BA) via RS485 bus system

- Serial digital interface for Ethernet Multiprotocol Modbus TCP, BACnet/IP for connection to building automation (BA) via RJ45 bus system

- Serial digital LON interface for connection to building automation (BA) via LONWorks bus system

- Serial digital PLR interface for connection to BA via company-specific coupling module

- Serial digital CANopen interface for connection to BA via company-specific coupling module

Dual pump management (twin-head pump or 2 x single pumps in Y-piece)

- Main/standby operation (time-dependent pump cycling)

- Main/standby operation (automatic fault-actuated switchover)

- Parallel operation (efficiency-optimised peak load cut-in and out)

Equipment

- Pump hydraulics with minimum efficiency index MEI ≥ 0.4

- EC motor with efficiency class IE5 according to IEC 60034-30-2

- Flange PN 16 – according to EN 1092-2

- Pressure measuring connections (R 1/8) for mounted differential pressure sensor (version ...-R1 without differential pressure sensor)

- Standard condensate drainage holes in the lantern and in the motor housing (closed upon delivery)

- Air vent valve on the lantern

- Rotatable colour graphics display (2 inch) with green button and one key

- Six cable inlets for connecting the power supply and the binary and analogue inputs (two cable entries factory-fitted with threaded cable glands)

- Optionally usable CIF module slot

Typekey

Example | Wilo-Yonos GIGA2.0-I 65/1-20/M-4.0-xx |

Yonos GIGA | Pump designation |

2.0 | Second generation |

-I | In-line single pump |

65 | Nominal flange diameter DN |

1-20 | Nominal delivery head range in [m] |

M- | 1~230-V power supply variant |

4.0 | Rated power in kW |

-xx | Variant, e.g. -R1 |

Technical data

- Permitted temperature range of the fluid: -20 °C to +120 °C

- Ambient temperature to +50 °C

- Mechanical seal for pumping water up to Tmax = +120 °C. Up to T ≤ +40 °C, a glycol admixture of 20 % to 40 % by volume is permissible. An alternative mechanical seal must be provided for water-glycol mixtures with a glycol content of > 40% to max. 50% by volume and a fluid temperature of > +40 °C to max. +120 °C or other fluids that differ from water. When using water-glycol mixtures, the use of an S1 variant with a corresponding mechanical seal is generally recommended.

- Mains connection:

- 3~440 V ±10%, 50/60 Hz, 3~400 V ±10%, 50/60 Hz, 3~380 V -5% +10%, 50/60 Hz

- Version M-: 1~220 V … 240 V ±10 %, 50/60 Hz

- Compliance with electromagnetic compatibility without additional measures:

- Interference emission for residential environment according to EN 61800-3:2018

- Interference immunity for industrial environments according to EN 61800-3:2018

- IP rating IP55

- Flange nominal diameter DN 32 to DN 125

- Max. operating pressure 16 bar up to +120 °C

Materials

- Pump housing and lantern: EN-GJL-250;

- Pump housing and lantern / motor flange with cataphoretic coating as standard

- Impeller (depending on type): PPO-GF30 (DN 32 … DN 80) or EN-GJL-200 (DN 100 … DN 125)

- Shaft: 1.4057

- Mechanical seal: AQ1EGG; other mechanical seals on request

Construction

- In-line pump with high energy efficiency ensured by motor with energy efficiency class IE5 in accordance with IEC 60034-30-2, hydraulics with minimum efficiency index MEI ≥ 0.4 and electronic power adjustment in glanded pump design.

- Single-stage low-pressure centrifugal pump with one-piece shaft in monobloc design

- Spiral housing in in-line design (suction and discharge ports with the same flanges in a line)

- Rotatable, graphic colour display (2 inches) with one button manual operation level

- Integrated motor protection

Scope of delivery

- Pump

- Installation and operating instructions and declaration of conformity

Options

- Variant …-R1 without differential pressure sensor

- …-S1 variant with special mechanical seal

Accessories

- 3 mounting brackets with fixation material for installation on a base

- Blind flanges for twin-head pump housing

- CIF module PLR

- CIF module LON

- CIF module BACnet MS/TP

- Modbus RTU CIF module

- CIF module CANopen

- CIF module Ethernet Multi-protocol (Modbus TCP, BACnet/IP)

- Connection M12 RJ45 CIF Ethernet

- Differential pressure sensor DPS 2 … 10 V

- Differential pressure sensor DPS 4 ... 20 mA