Exceed environmental requirements with efficient systems for a future-proof wastewater treatment plant!

Ready for the next level of sewage treatment? The steadily increasing requirements for water quality and operational reliability necessitate reliable machine technology for wastewater treatment plants.

Wilo offers sustainable and particularly efficient solutions for the effective removal of micropollutants from water – for optimal water quality! Their adaptable design makes them incredibly easy to install. Furthermore, their digital data sets (BIM) allow them to be perfectly integrated from as early as the concept phase. For example, a combination of powdered activated carbon (PAC) and effective separation technologies can be used to eliminate not only micropollutants but also antibiotic-resistant bacteria.

For us, future-proof water treatment also means maximum energy efficiency. In this way, we lower your energy costs in addition to reducing your carbon footprint with efficient machine technology. Optimise your processes – don’t just meet environmental requirements, exceed them!

Ensure effective sewage treatment – by integrating a membrane filter

Our membrane filters can be integrated into existing activated sludge tanks as a membrane bioreactor (MBR). Our membrane bioreactors guarantee efficient filtering of bacteria (including antibiotic-resistant bacteria) and viruses. Combined with the addition of powdered activated carbon, the system effectively adsorbs and removes micropollutants. The membrane’s ultrafiltration spores guarantee 100% retention of ultra-fine activated carbon and microplastics. In this way, wastewater treatment systems can be easily retrofitted and expanded in existing spaces. The robust design and substance-to-substance welded membrane make for a particularly long service life. Enjoy sustainable water treatment and micropollutant removal when you choose our membrane filtration from Marton Systems.

Learn more at Abionik – A Wilo companyEnsure improved sediment performance – with innovative separation geometry

The diagonally inclined lamella separator filters fine particles in water in addition to effectively removing previously added powdered activated carbon, significantly reducing the necessary secondary treatment volume. The fixed and diagonally arranged lamellae make for a large settling surface, reducing the surface load and increasing sediment performance. The powdered activated carbon loaded with micropollutants is deposited between the plates without any additional energy input. With its expandable modular system, the diagonally inclined lamella separator is a compact, environmentally friendly and energy-efficient solution!

Learn more at Abionik – A Wilo companyEnsure reliable sewage transport – even during micropollutant removal.

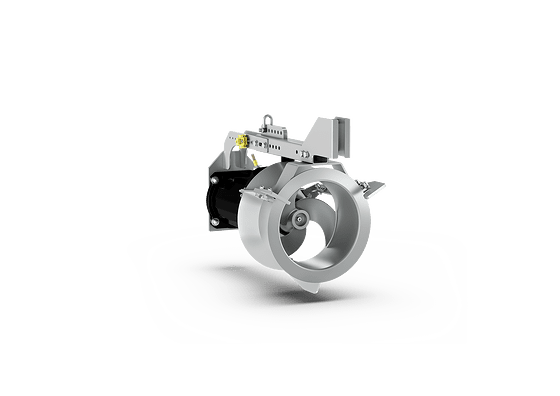

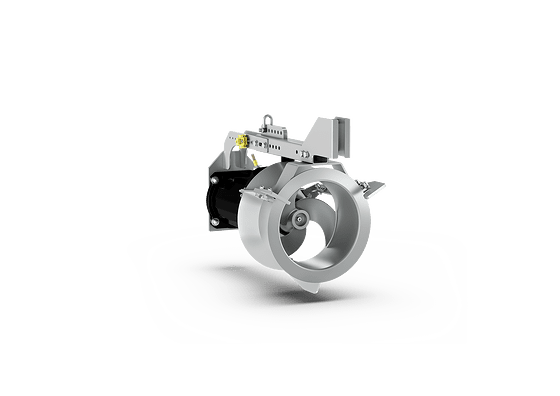

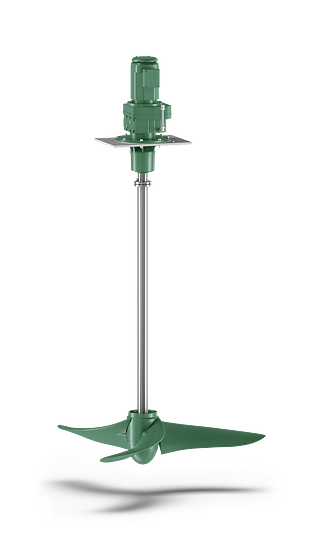

The new, highly efficient Wilo-Flumen OPTI-RZP and Wilo-Flumen EXCEL-RZPE series ensure reliable continuous operation in a non-clog design. The Wilo recirculation pumps are configured taking into account the customer-specific requirements, existing pipe diameters and necessary volume flows. Installation can also be carried out on existing piping by means of specific connections and settings on the flow housing. The use of stainless-steel investment-cast propellers makes the Wilo-Flumen OPTI-RZP and Wilo-Flumen EXCEL-RZPE ideally suited for continuous operation, and their modular design makes them service-friendly.

Find out more nowChoose operational reliability and flexibility – as a dry installation in the pump chamber

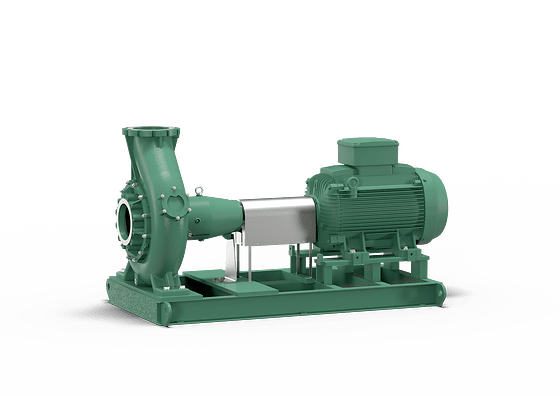

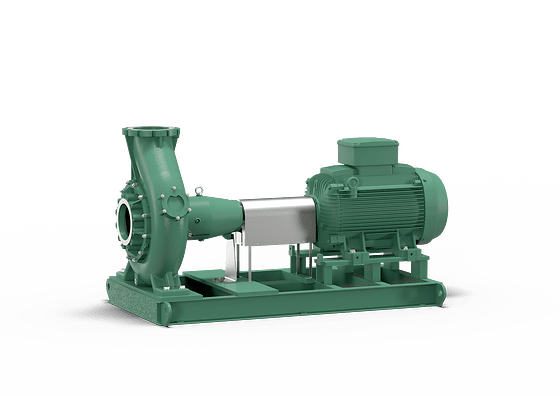

As a stationary dry installation in wastewater treatment plants, the Wilo-Rexa BLOC ensures reliable sewage transport and micropollutant removal. The compact sewage pump with an IEC standard motor as a monobloc unit is available for both horizontal and vertical installation. The IE3/IE4 energy efficiency class ensures that our standard motors operate very economically, including during continuous operation. Reliable sewage pumping operation is technically ensured by proven hydraulics with a vortex or a single-channel impeller. The back-pull-out design lowers maintenance costs and with them operating expenses.

Make a difference and save up to 16 tonnes of CO2.

Read our focus paper to learn more about our solution for micropollutant removal in wastewater treatment systems with upstream denitrification.

Click here to download the focus paper now and deepen your knowledge.Discover how harmful micropollutants come to contaminate sewage and how our products and technologies can effectively help you with micropollutant removal.

Other efficient products for your wastewater treatment plant:

-

Wilo-Flumen EXCEL-RZPE 20 ... 40

-

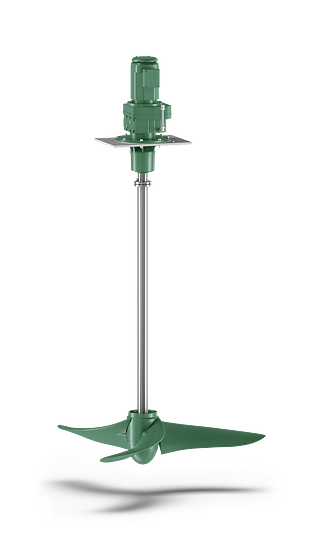

Wilo-Vardo WEEDLESS-VM

-

Wilo-Rexa NORM

Imamo odgovore na vaša pitanja

Da li vas naši proizvodi i usluge interesuju? Ako je tako, rado жemo pomoжi!

Bilo da kreirate novi projekat ili podešavate specifikacije usluge, dizajnirate različite vrste opreme, savetujete izbor pumpi i prekidača ili samo pomažete u hidrauličnim i kontrolnim problemima.

Moћemo da vam pomognemo! Molimo vas da kontaktirate naš servisni tim da zakažete sastanak

Pronađite pravi kontakt za vaše pitanje.