There are two types of installations where centrifugal pumps can be used. These are open pump systems, such as drinking water systems and closed pump systems, such as heating and cooling systems.

Open pump systems

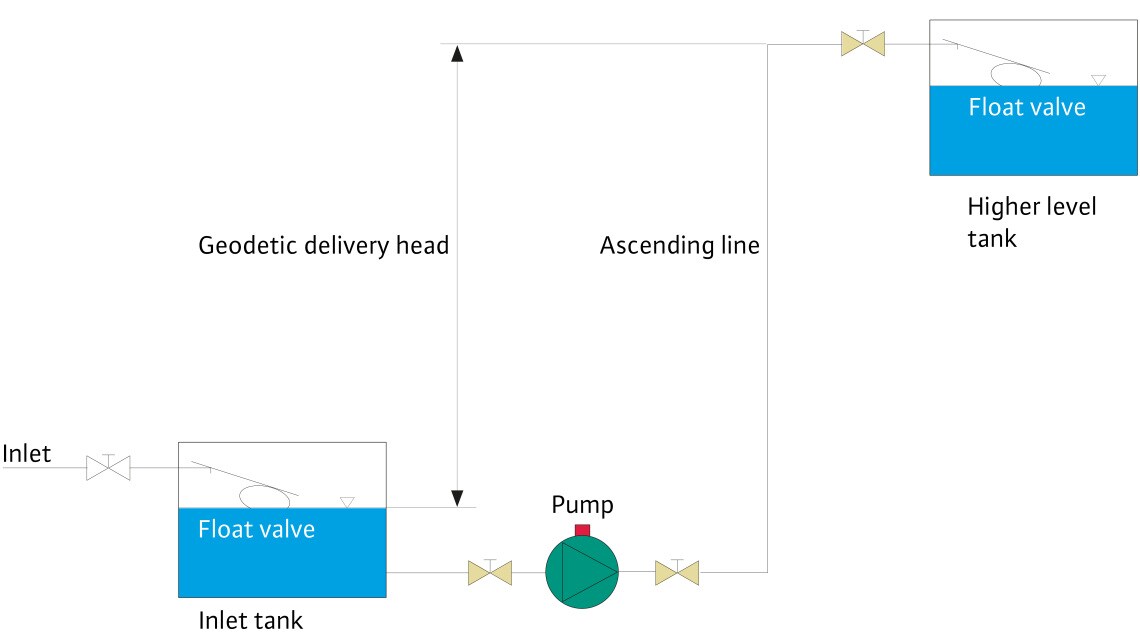

With an open pumping system, the fluid must be pumped from a low-lying supply reservoir to an elevated reservoir. The pump transports the water from the lower reservoir to the desired height.

It is not sufficient to adapt the flow rate of the pump to the geodesic head because at the last tapping point, e.g. a shower on the top floor in a hotel, the pressure should still be high enough. The friction losses that arise in the ascending pipe must also be considered.

Pump head = geodesic head + pressure + pipe losses

For necessary maintenance work, the individual pipe segments must be able to be closed off by means of taps. This applies in particular to pumps because otherwise enormous quantities of water will have to be drained from the ascending pipes for repair or replacement of the pump.

Float valves or other control elements must also be provided in the lower supply tank and in the upper tank to prevent any overflow.

In addition, a pressure switch can be installed in the ascending pipe at a suitable location which switches off the pump when all draw-off points are closed and no more water is drawn off.

Pump system for transporting water to a higher level

Closed pump systems

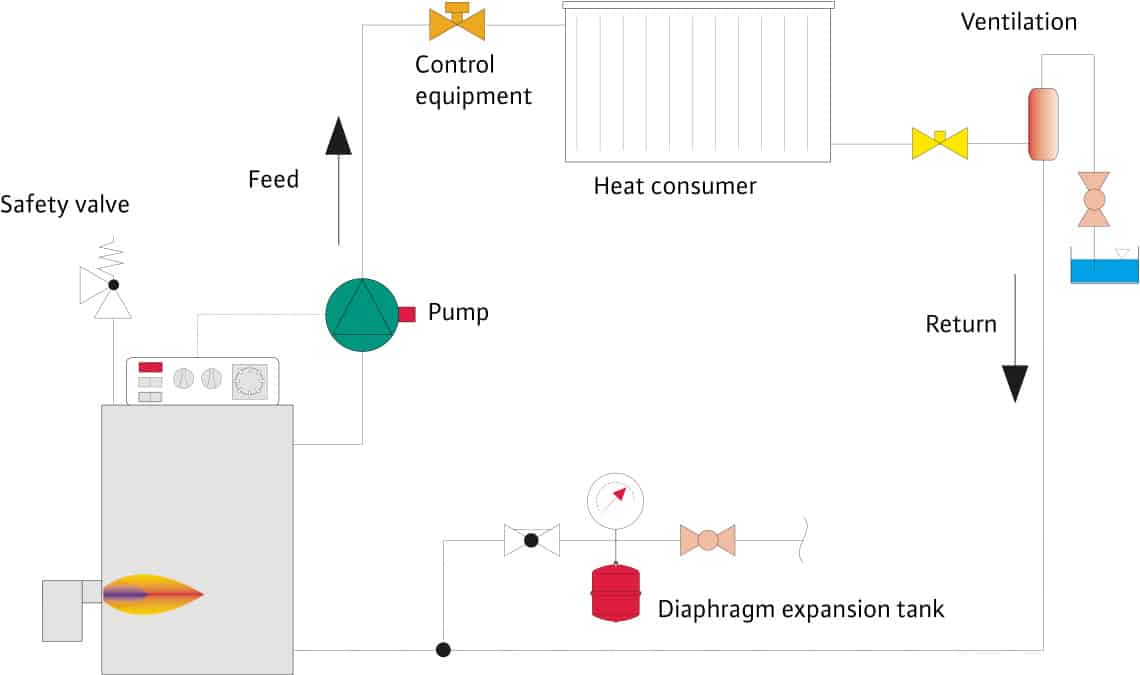

While a water pump system is an open system with a free outlet (for example, a tap in the form of a faucet), a heating installation is a closed system.

This principle is even easier to understand if we imagine that the heating water in the pipes is simply keeps moving or circulates.

The heating system can be divided into the following elements:

- heat source;

- heat transport and distribution system;

- diaphragm expansion tank for maintaining and controlling pressure;

- heat consumers;

- control system;

- safety valve.

Heat sources here refer to heating boilers and such, on gas, oil or solid fuel. This also includes electric night-time heaters with central water heating, district heating stations and heat pumps.

The heat transport and distribution system include all pipes, distribution and collection stations and of course the circulator. The pump capacity in a heating installation must only be designed in such a way that all resistance, such as bends, fittings, pipe diameters of the installation are overcome. The height of the building is not taken into account because the water that is forced into the supply pipe by the pump pushes the water in the return pipe back to the boiler.

Circulation system based on an example of a heating installation

Centrifugal pump with pressure vessel

The diaphragm expansion tank is responsible for compensating for the changing water volume in the heating installation depending on the operating temperatures, while at the same time keeping the pressure stable. Heat consumers are the heating surfaces in the rooms to be heated (radiators, convectors, panel heating, etc.). Heat energy flows from points with a higher temperature to points with a lower temperature and the greater the temperature difference, the faster. This transfer takes place through three different physical processes:

- heat conductivity;

- convection, i.e. rising air;

- heat radiation.

Today, no technical problem can be solved without proper control. It goes without saying, for example, that there are control systems in every heating installation. The easiest to understand in this regard are the thermostatic valves to keep the room temperature constant. But also in boilers, mixers and of course pumps, there are now innovative mechanical, electrical and electronic controllers.