An electric motor drives, as described, the pump shaft, on which the impeller sits. The pressure increase generated in the pump and the flow pumped by the pump is the hydraulic result of the electrical drive energy. The energy required by the motor is indicated by the power consumption P₁ of the pump.

Output curve of centrifugal pumps

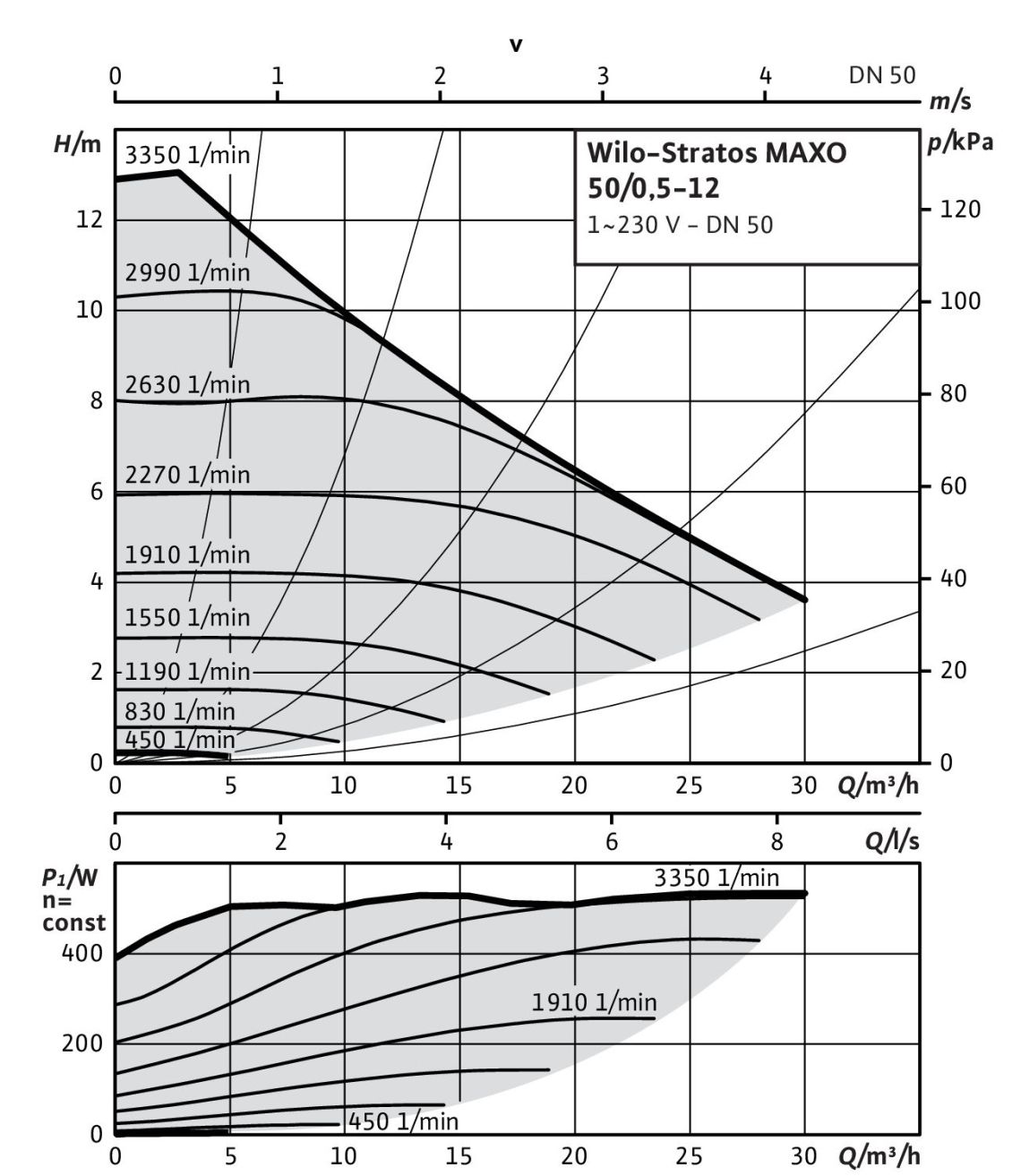

The output curve of centrifugal pumps is shown in a graph: on the vertical axis, the ordinate, the absorbed power P₁ of the pump in watts [W] is noted. The flow rate of the pump in cubic metres per hour [m3 / h] is noted on the horizontal axis, the abscissa, as is the case with the pump characteristic to be treated. The scale division is chosen on the same scale. These two characteristics are often shown below each other in catalogues so that the relationship is clearly visible.

In general, the performance curve shows the following relationships: at a low flow rate, the motor has the lowest power consumption. This increases with increasing flow rate. The required power changes in a significantly stronger ratio than the flow rate.

Example of relationship between pump characteristic and power characteristic (Stratos MAXO 50 / 0.5-12)

The influence of the motor speed on the output curve of centrifugal pumps

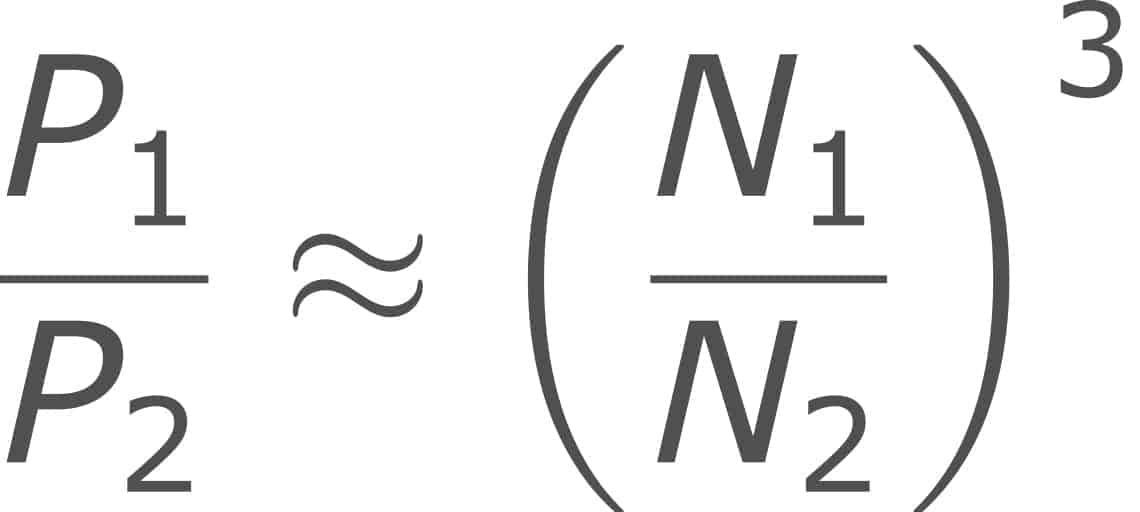

If the speed of the pump is changed for the rest of the installation conditions, the absorbed power P changes practically proportionally to the cube of the speed n.

Formula to calculate the efficiency of a centrifugal pump

With this knowledge, the pump can be sensibly controlled and the heating energy requirement can be adjusted. If the speed is doubled, the flow will increase in the same proportion. The head increases up to four times. The necessary driving energy is then approximately eight times. If the speed is reduced, the flow rate, the head in the pipe system and the required power are reduced in the same proportions as described above.

Fixed speeds depending on the design

A characteristic difference between centrifugal pumps is the head, depending on the motor used and the predetermined fixed speed. In this case, a fast-running pump with a speed of n> 1500 rpm is referred to as a high-speed runner and a slow-running pump with a speed of n <1500 rpm is referred to as a slow-runner.

The slow-runner motor construction is slightly more advanced and therefore the price of these pumps can be slightly higher. However, where the heating circulation conditions make it possible or even necessary to use a slow-running pump, the faster pump leads to unnecessary high power consumption. The higher purchase costs required for speed reduction lead to significant savings in drive energy. The extra investment is therefore often quickly recouped.

With controlled speed reduction in accordance with the reduction in heating demand, the continuous control of the pump electronics provides significant savings.