Wilo-SiBoost2.0 Smart 1 Helix VE

Optimal pressure boosting. Intuitive operation.

Optimal pressure boosting. Intuitive operation.

The Wilo-SiBoost2.0 Smart 1 Helix VE provides reliable water supply in large buildings at all times due to integrated protection functions. These include overload protection, dry-running protection and low-water cut-out switchgear with automatic deactivation.

Furthermore, significant energy savings are achieved through pressure-loss-optimised hydraulics as well as optimal load adjustment.

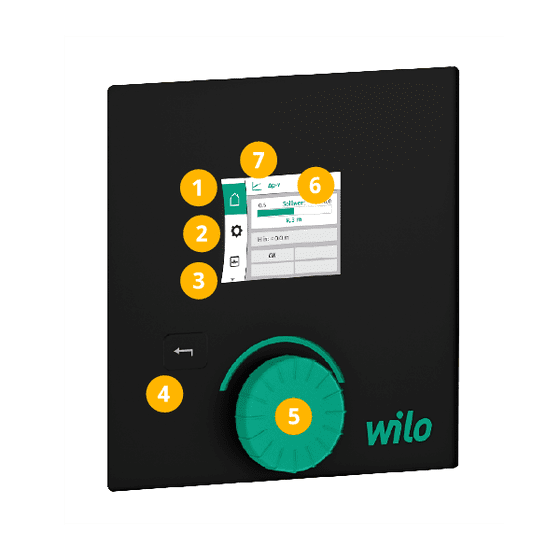

The colour display enables optimal operating convenience by displaying visualisations and plain text.

Recommended services

Your advantages

- Heavy-duty system featuring stainless steel multistage centrifugal pump from the Helix2.0 VE series with an integrated frequency converter with large control range

- Energy saving due to IE5 EC motor technology and pressure-loss optimised overall system

- Rotary knob and clear menu navigation in the colour display enable an easy operation

- Needs-based pressure boosting through the extra control mode p-v

- High reliability through integrated protection functions and low water detection (WMS)

- Ready for integration into building automation via optional CIF-modules and optional extended communication via Wilo-Gateway

- All components that come in contact with the fluid are suitable for drinking water

Design

Highly efficient water-supply unit ready for connection, with a vertically arranged, non-self-priming, stainless steel, high-pressure multistage centrifugal pump from the Helix2.0 VE series, equipped with integrated, air-cooled frequency converters.

Application

- Fully automatic water distribution and boosting in inlet mode, either from the public water supply network or from a tank, for domestic, commercial, industrial and municipal applications (a standby pump must be provided in accordance with the requirements of DIN 1988 and DIN EN 806).

- Approved fluid is water which does not corrode the materials used, neither chemically nor mechanically, and does not contain any abrasive or long-fibre constituents.

Liquid

- Drinking water (drinking water approval in Check Material section)

- Cooling water

- Process water

- Firefighting water (apart from fire-fighting systems in accordance with DIN 14462 and with the approval of the local fire protection authorities)

Equipment/function

- One pump from the Helix VE 2 to Helix VE 52 series, with IE5 EC motor drive and speed control with integrated frequency converter, mounted on height-adjustable, zinc-coated steel base frame.

- All components in contact with fluid are corrosion- resistant.

on the discharge side:

- Shut-off valve

- Non-return valve

- Non-return valve

- Diaphragm pressure vessel 8 l, PN 16

- Pressure sensor 4 ... 20 mA

- Pressure gauge

On the suction side:

- Pressure sensor 4 ... 20 mA

- Pressure gauge

Typekey

Example: | Wilo-SiBoost2.0 Smart 1Helix VE606-HS |

SiBoost2.0 Smart | Compact pressure-boosting system with integrated speed control |

1 | Number of pumps |

Helix VE | Helix2.0 VE pump series |

6 | Rated volume flow [m³/h] of the single pump |

06 | Number of single pump stages |

-HS | With main switch |

Technical data

- Mains connection: 3~400 ±10%, 50 Hz; 3~380 ±10%, 60 Hz

- Max. fluid temperature: +50 °C (+70 °C optional)

- Max. ambient temperature: 40 °C

- Operating pressure: 16 bar (25 bar optional)

- Inlet pressure: 10 bar

- Nominal connection diameters:

- On the end pressure side: R 1¼″ – DN 80

- On the inlet side: Rp 1¼″ – Rp 3″

- Speed range: 1500 – 3500 rpm

- Protection class: IP54

Materials

- Pump housing made of 1.4301 [AISI 304]

- Hydraulics made of 1.4307 [AISI 304L]

- EPDM gasket

- without cartridge

Other pump versions available on request:

- with cartridge

- PN 25

- FKM (Viton) gasket

- Pump housing made of stainless steel and hydraulics made of 1.4404 [AISI 316L]

Construction

Base frame: Galvanised steel, with height-adjustable vibration absorbers for comprehensive insulation against structure-borne noise as well as integrated lifting points.

Pipework: Entire pipework made of stainless steel on the discharge side; suitable for the connection of conventional pipe materials. The pipework is designed pursuant to the overall hydraulic performance of the pressure-boosting system

Pumps: One pump from the series Helix2.0 VE 2 to Helix2.0 VE 52 is used.

The air-cooled frequency converters mounted on the pump motor enable continuous control between 25 Hz and a maximum of 60 Hz for all pumps of this series.

- All pump parts in contact with liquids are made of stainless steel with KTW/WRAS/ACS approval.

Valves: The pump is fitted on the discharge side with a standard-equipped shut-off valve and on the discharge side with a DVGW/KTW approval non-return valve.

Diaphragm pressure vessel: 8 l/PN 16 arranged on the end pressure side with a diaphragm made of butyl rubber, with DVGW/KTW approval, completely safe in accordance with food safety laws; shut-off ball valve attached for testing and inspection purposes with drain and throughflow fitting with DVGW/KTW approval according to DIN 4807.

Pressure monitoring: 2 pressure sensors: 4..20 mA, arranged on the discharge side and on the suction side.

Pressure indication: Pressure gauges arranged on the suction and end pressure side.

Available in other versions on request.

Scope of delivery

- Factory-mounted, ready-for-connection pressure-boosting system checked for functionality and impermeability

- Installation and operating instructions

- Factory test protocol

Installation and operating instructions

Wilo-SiBoost 2.0 Smart 1, Wilo-SiBoost Smart 1, Wilo-Comfort-Vario COR-1...-GE, Wilo-Comfort-Vario COR/T-1…-GE

| Article Number | 2535459 |

| Edition | 2023-08 |

| Number of pages | 72 |

| Language | en |

Wilo-Helix V, .. FIRST V, ..2.0-VE 2-4-6-10-16

| Article Number | 4143727 |

| Edition | 2023-03 |

| Number of pages | 24 |

| Language | en |