Quality assurance

Quality with certainty – from development to the customer. This is Wilo’s uncompromisingly high standard for all processes along the value chain. To ensure the highest quality and reliability of our products, solutions and services at all times, we involve suppliers, laboratories, service and sales units as well as customers in our quality management. In this way, we work together to shape a new understanding of forward-looking quality assurance: in other words, Quality Management 4.0.

Preventative risk management

Risks indentified and eliminated in advance

In order to identify risks to uncompromising product reliability and eliminate them before market launch, Wilo systematically analyses and evaluates potential sources of influence. In this way, we ensure the continuous optimisation of numerous technical parameters and minimise the failure rate even before our products are ready for series production.

Our risk management involves:

Considering technical risks and measures

Failure Mode and Effects Analysis (FMEA)

Field tests

Supplier selection

Material quality controlled at an early stage and without interruption

In the run-up to each new product development, Wilo analyses the supplier environment and identifies the ideal project partners. Continuous material tests and process controls ensure that all relevant quality standards are already checked and adhered to during sampling – i.e., in the early stages of product development.

Our measures include:

Remote audits

Interactive drawing reviews

Process reviews

Laboratory tests

Reliability guaranteed at every stage of the product life cycle

Laboratory tests before and during development ensure that materials and components withstand the highest stresses and that the finished product functions reliably. Based on specific customer requirements, we develop standardised and specific scenarios to test all functions under different conditions (Book of Qualifications; BoQ).

Our laboratory tests include:

Functional tests

Material tests

Long-term/ageing tests

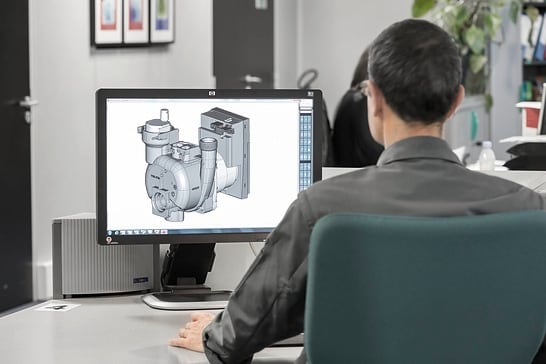

Digitalisation and collaboration

Seizing the opportunities of digital transformation

Quality management processes and standards are in a constant state of change. Simulations, AI-supported projections and digital forms of collaboration are increasingly shaping work processes and results. Wilo consciously uses the resulting opportunities to increase transparency and traceability.

Our digitisation measures take into account:

Analyses and conversion of Big Data to Smart Data

Competence networks via social media

Digital remote acceptance and maintenance

Employee qualifications

Actively shaping change

The digital transformation has fundamentally changed working methods and self-perceptions in quality management. Instead of reactively checking product and material quality in incoming and outgoing goods, employees today design the entire process chain on the basis of predictive data. Wilo consciously promotes digital skills and agile forms of working.

Our qualification measures include:

Digital process management

Intercultural competence

Agile collaboration according to Gemba principles