Energy and Emissions

A considerable portion of global energy consumption is caused by electric pumps. We are aware of the enormous potential of efficient technology and want to spread this more widely in the interests of climate protection. This is why we consider ourselves to be a climate protection company. Our goal is to save 1.8 TWh of electricity per year by using high-efficiency pumps.

Hydrogen - a small molecule with big potential

Ways to efficiently store, transport and distribute CO2 - free energy will be needed for the global energy transition to succeed. Green – CO2 -free – hydrogen is an ideal solution. There are different ways of producing hydrogen. To use it as a clean form of energy, it has to be generated by the electrolysis of water using only electricity from renewable sources, meaning that the resulting hydrogen is carbon-neutral.

Wilo already has numerous products and solutions in its portfolio that can be used in the first stage, i.e. generation and storage, from reverse-running pumps for driving hydropower generators and pumps for cooling circuits in wind turbines through to rotor drive actuators for these turbines. And as hydrogen makes its way to the end user, there are further wide-ranging possibilities for using Wilo’s products, solutions and services, including in areas such as fuel cell technology

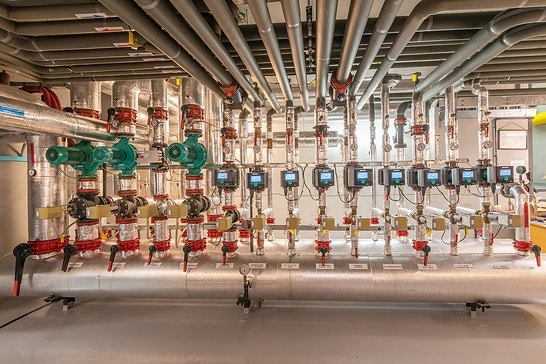

High-efficiency pumps

Wilo supplies highly efficient technology for all areas of application in building services, water management and industry. The focus is on maximum reliability and energy-saving, reliable operation. High-efficiency pumps are electronically controlled and adapt to the system’s actual requirements. A special drive, the permanent magnet motor, forms the basis of the energy-saving potential of Wilo’s high-efficiency pumps. A pump with this technology consumes up to 80 percent less electricity than a comparable uncontrolled pump

Wilo-Energy Solutions

Wilo-Energy Solutions is part of our service range, which covers the entire life cycle of our products. This enables optimum energy efficiency with smooth and low-maintenance operation. In addition to the energy efficiency of the motors, the design of the pump system also plays a key role for energy-saving potential. This potential cannot be fully tapped without the right sizing.

Municipal infrastructure

The town of Bad Hersfeld replaced old pumps in municipal buildings for highly efficient Wilo pumps in a big way. 60 new Wilo pumps in a total of 24 municipal buildings are now operating at high efficiency – from the town’s library to its kindergartens and multipurpose halls. And more are set to follow. The town now saves 29,000 kWh of electricity and more than 17 tonnes of CO2 per year.

Smart Programs

The trend towards digitisation and the emerging opportunities for further efficiency enhance - ment are making smart systems solutions an essential tool in slowing climate change. Wilo is therefore investing in the development of smart products and aiming for an annual growth rate of at least 15 percent. We define smart-pumps as a category of pumps that goes far beyond our high-efficiency pumps or pumps with pump intelligence. The combination of cut - ting-edge sensor technology and innovative control functions, bi-directional connectivity, software updates and excellent user-friendliness make a pump a smart pump.

Modernisation

As part of an extensive modernisation project, we successfully equipped several buildings in the city of Prague with our smart products last year. In total, old pumps were replaced with Wilo pumps from the Wilo-Stratos MAXO, Wilo-Stratos MAXO-Z and Wilo-Stratos GIGA-D series in six municipal facili - ties. The main selection criterion was the innovative Dynamic Adapt plus function, which enables addi - tional savings compared to other modern pumps. Another necessary requirement was the ability to connect to a building automation system and thus control the entire system. The results speak for themselves: total heating consumption in buildings was reduced by 11 percent and water consumption by 20 percent. Power consumption was halved. Over the total lifetime of the project, the smart pumps will save up to 37,615 tons of CO 2 equivalent.

Emissions in production and processes

Wilo is a climate protection company. Being selected as one of the world’s “50 Sustainability & Climate Leaders” and winning the German Sustainability Award in the Climate category simultaneously both challenge and inspire us. The goal is to make our 15 main production sites around the world carbon-neutral by 2025.

The four production sites at our head office in Dortmund became climate-neutral in 2020. The new smart factory in particular accounts for a lot of this: the absolute energy savings compared to the old factory building are around 30 percent.

The power supply has been based on green electricity for years already, and requirements are now also covered by our own photovoltaic system. The remaining approximately 3,000 tonnes of CO2 are compensated by a gold-certified project in Malawi that improves the local drinking water supply by maintaining wells. TÜV Rheinland checked and confirmed that the data were complete and correct; Wilo thus received the “climate-neutral company” mark of conformity.