Centrifugal pumps and types of suction

Centrifugal pumps come in many different shapes and sizes. For the correct choice, it is useful to know which types there are.

Self-priming centrifugal pump

A self-priming pump can vent the suction pipe to a certain extent,i.e. evacuate air. During commissioning, the pump may have to be filled several times. The maximum suction head is theoretically 10.33 m and depends on the air pressure (101 hPa = normal).

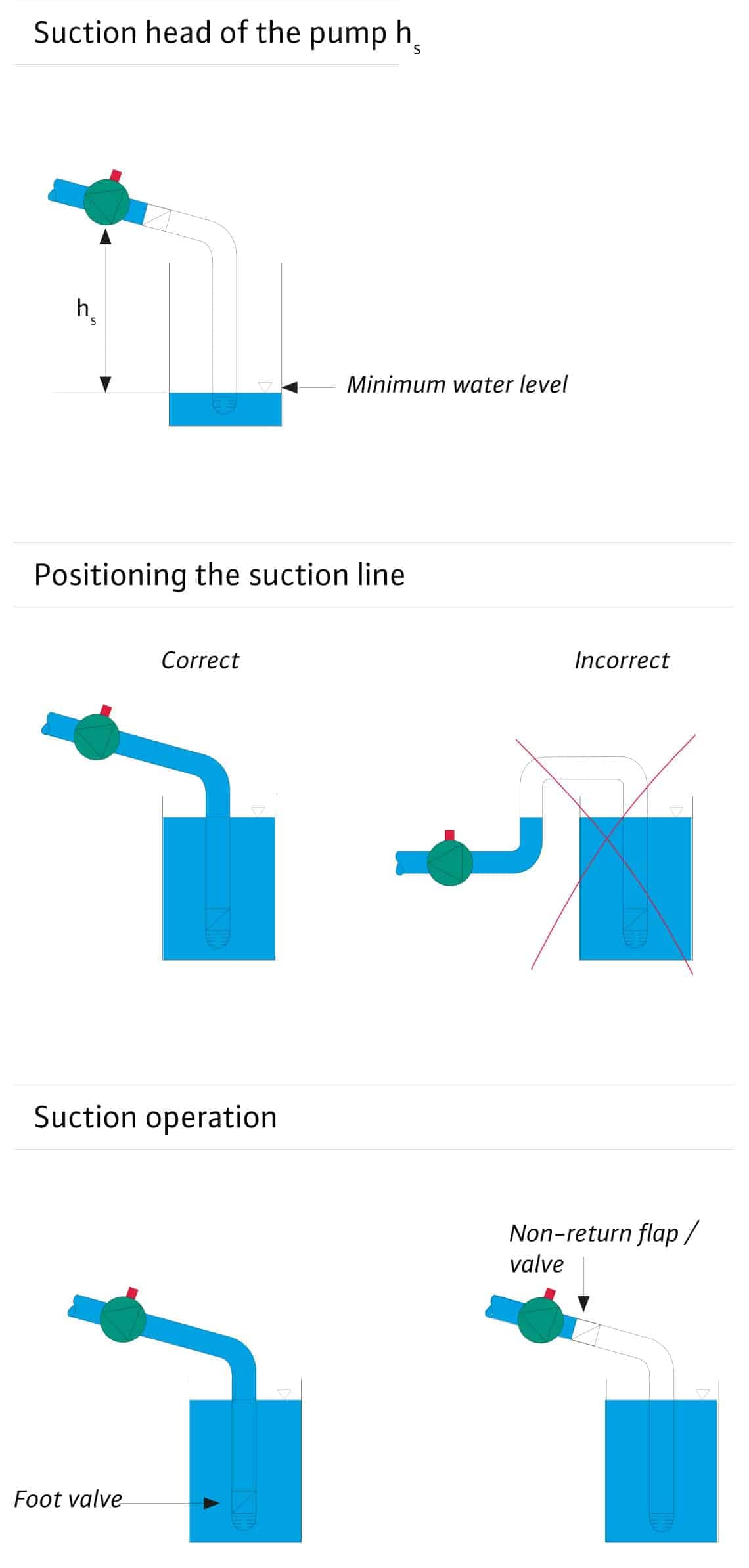

From a technical point of view, however, only maximum 7-8 m suction head Hs can be achieved. This value does not only include the difference in height from the deepest possible water level to the suction opening of the pump, but also the resistance losses in connection pipes, pump and fittings.

When selecting the pump, it must be considered that the suction lift Hs must be negatively included in the calculation of the delivery head.

The suction line must be installed at least with the nominal diameter of the pump connection, if possible, by one value greater, and it must be kept as short as possible.

With a long suction line increased frictional resistance is created and as a result, the suction head Hs is very adversely affected.

The suction line must be laid constantly rising towards the pump and when using hose material as the suction line, spiral suction hoses should be preferred (density, strength). Leaks must be absolutely avoided, as otherwise the pump can be damaged and malfunctions can occur.

Centrifugal pump with filter

In suction mode, a non-return valve is recommended to prevent the pump and suction line from emptying. A foot valve with suction strainer also protects the pump and the systems coupled behind it against coarse contamination (leaves, wood, stones, vermin, etc.). If a foot valve cannot be used, a non-return valve/valve must be installed downstream of the pump (pump suction opening) for suction operation.

Non self-priming centrifugal pump

A self-priming pump is not able to evacuate air from the suction line. With non self-priming pumps the pump and the suction line must always be completely filled.

If air enters the pump through leaks, at the stuffing box of a valve or through a non-closing foot valve in the suction line, the pump and the suction line must be refilled.

Multi-impeller centrifugal pump

Typical construction features of high-pressure centrifugal pumps are the linked construction with impellers and stage chambers.

The flow rate of a pump depends, among other things, on the size of the impellers. Several impellers/guide vanes placed one behind the other ensure the delivery head of high-pressure centrifugal pumps. Here the kinetic energy is partly converted into pressure in the impeller and partly in the guide vane placed behind it.

The multiple stages allow the high-pressure centrifugal pumps to reach pressure levels that are unfeasible when using single-stage low-pressure centrifugal pumps.

Very large types can even have twenty stages. This allows delivery heads of up to 250 m to be achieved. The described high-pressure centrifugal pumps belong almost exclusively to the glanded pump family. Recently it has been possible to equip these with glandless motors.

Previous FAQ entry:

In what types of installations can I use centrifugal pumps?Next FAQ entry:

How do I select the right centrifugal pump?We have answers to your questions

Do our products and services interest you? If so, we are happy to help!

Whether you're creating a new project or adjusting service specifications, designing different types of equipment, advising on the selection of pumps and switchgear, or just helping with hydraulic and control issues.

Please contact us - we'd be happy to help.

Find the right contact for your question.