The lowdown on circulating pumps for heating systems – so-called heating pumps

Heat wouldn’t be able to reach rooms without a heating pump. Circulating pumps, in particular modern high-efficiency pumps, pump heated water through the heating system. The comfortable warmth is released into the room via classic radiators or surface heating such as underfloor heating. However, the permanent operation of heating pumps can entail high electricity costs. Find out here how to reduce energy costs and enhance comfort.

Circulating pumps for commercial and domestic heating systems

What’s the deal with heating pumps? How can energy be saved with suitable systems? How can installers like you simplify installation, optimise maintenance and increase your customers’ satisfaction? Wilo’s got the answers for you here. Our high-efficiency pumps for detached and semi-detached houses as well as for commercial buildings stand out due to their innovative technologies. They also impress with their reliability and high level of quality. As an installer, you benefit from these features. Not to mention that our high-efficiency pumps save your customers considerable costs. Benefit from our years of experience from projects in building services. We’ll support you both in the design stage and during the implementation phase of your projects.

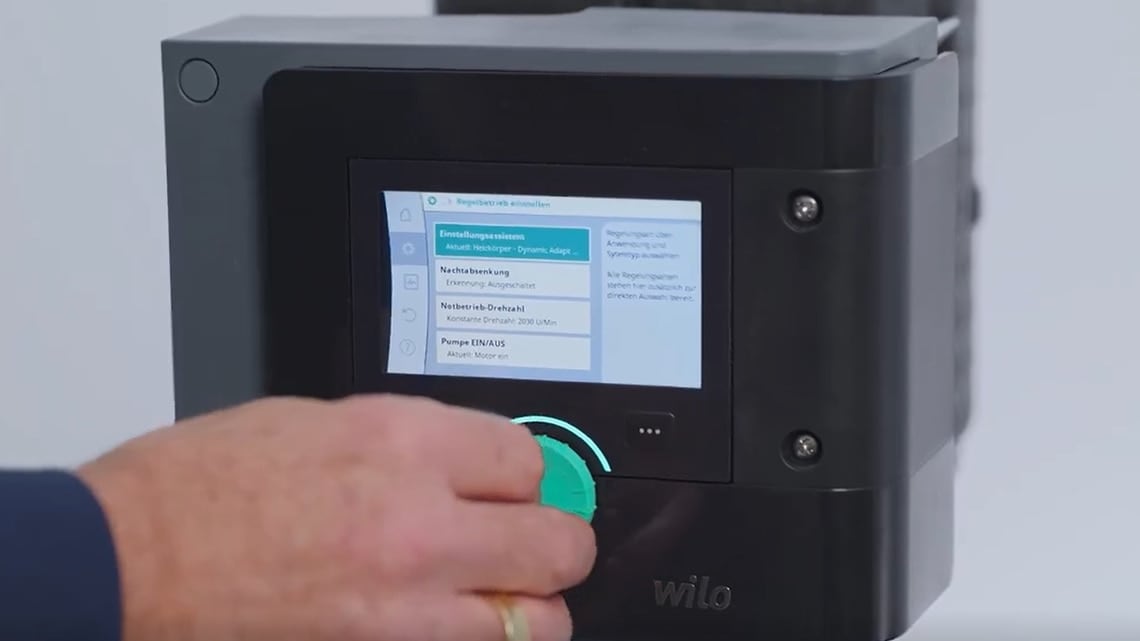

Commissioning circulating pumps for heating systems

Find out here how you can considerably simplify and speed up the often time-consuming commissioning process with Wilo’s high-efficiency pumps. We provide you with innovative solutions: setting assistant, one-click commissioning, Green Button Technology and Wilo-Connector.

Read moreReplacing circulating pumps for heating systems

Old heating pumps run continuously and guzzle electricity at a high price. In contrast, a modern high-efficiency pump saves up to 80 per cent electricity. It therefore makes sense to replace old pumps. Find out here why replacement is worthwhile and what should be taken into account.

Read moreFAQs – frequently asked questions about circulating pumps or heating pumps

What’s the difference between a heating pump and a circulating pump?

They’re the same thing: a heating pump, also referred to as a circulating pump, transports the heated water in the so-called feed from the boiler to the individual radiators. The pump returns the cold water to the boiler via the return, where it is heated up again. A heating pump is therefore the heart of a heating system.

How much electricity do old, fixed-speed heating pumps consume?

Old, fixed-speed heating pumps run continuously at a high speed and are responsible for about 20 per cent of the world's electricity consumption. A detached house runs up huge electricity costs per year – up to 10 % of the total power consumption because the old pump is not controlled according to actual demand. It runs at a permanently high speed for up to 6,000 hours per year and transports the water to the connected radiators and underfloor heating systems. On average, an old, fixed-speed heating pump consumes approx. 600 kWh per year for a detached house. By way of comparison, comparable modern high-efficiency pumps consume 40 kWh per year.

What is a high-efficiency pump or high-efficiency circulating pump?

A high-efficiency pump for heating systems is a modern central heating pump developed to reduce the energy consumption and operating costs of heating systems. High-efficiency pumps are fitted with integrated electronic controls that enable variable speed control. This allows the pump to automatically adapt its operation to the actual heat requirements of the heating system. Wilo’s high-efficiency pumps are considerably more energy-efficient than old, fixed-speed heating pumps. This reduces electricity consumption and CO2 emissions.

And there’s more: the increase in efficiency leads to cost savings, which means that the new pump quickly pays for itself. They’re also quieter in operation and offer better controllability, increasing comfort and extending the service life of the heating system.

Why are high-efficiency pumps quieter?

How environmentally friendly are circulating pumps for heating systems?

How environmentally friendly a circulating pump is depends on its efficiency and the technology used. High-efficiency pumps like those from Wilo are considered to be significantly more environmentally friendly compared to older, fixed-speed pumps. They consume less energy and thus reduce CO2 emissions. The variable speed control and adaptation to the actual heat requirements of the heating system further reduce energy consumption. This pollutes the environment less and helps achieve climate action goals. Nevertheless, it’s important to also consider other aspects of the heating system in order to assess environmental friendliness. This includes the efficiency of the heat generation, the insulation of the building and carrying out hydronic balancing. The more efficient and better coordinated the various components of the heating system are, the more environmentally friendly the overall system is.

How can you make a heating system even more efficient?

Hydronic heating systems are already considered to be one of the most efficient heating systems available. However, there are several ways to further increase the efficiency of such a heating system.

- Insulate pipes

- Use zone control

- Use a high-efficiency pump

- Carry out hydronic balancing

Also see: Hydronic balancing of heating systems

How is the delivery head of the circulating pump determined for heating systems?

Determining the delivery head is an important step when selecting the right pump for a certain application. The delivery head is the measure of the pressure with which the heating pump forces the heating water through the pipes. Wilo provides you with helpful online tools with the slide rule and pipework calculator:

Pipework calculatorThe characteristic curve shows you the interrelations. The electrical drive energy (taking into account the overall efficiency) is converted in the pump into the hydraulic energy forms of pressure boosting and movement. If the pump runs against a closed valve, this results in the maximum pump pressure. This is referred to as the zero-delivery head of the pump. If the valve is opened slowly, the fluid begins to flow. As a result, part of the drive energy is converted into kinetic energy. The original pressure can then no longer be maintained. The pump curve slopes downwards. In theory, the point of intersection of the pump curve with the volume flow axis is reached when the water only contains kinetic energy and no more pressure is built up. However, since a pipeline system always has an internal resistance, the real pump curves end before the volume flow axis has been reached.

Select the Wilo high-efficiency pump with the right delivery head. This ensures that the pump conveys the heating water through the system effectively.

See also: Commissioning circulating pumps for heating systems

What is the relationship between pump efficiency and volume flow?

The efficiency of a pump is the ratio between the power output of the pump and the input power. The input power is the amount of energy required to operate the pump whereas the power output is the amount of energy transferred to the pumped fluid.

The efficiency of a pump can vary depending on numerous factors, including volume flow. The relationship between pump efficiency and volume flow can be described using the pump performance curve.

A performance curve is a diagram that illustrates the relationship between volume flow and pump efficiency for a specific pump model.

The BEP (Best Efficiency Point) is approx. 2/3 of the maximum flow rate (Qmax). Efficiency therefore does not decrease with increasing volume flow. If the pump operates against a closed valve, a high pump pressure is achieved, but since no water flows, the effect of the pump is equal to zero. The same applies with an open pipe. Despite a large amount of water, no pressure is built up and thus no efficiency is achieved. The best overall efficiency of the heating circulation pump

is in the middle range of the pump curve. These optimum operating points are specially marked for each pump in the manufacturers’ catalogues.

IMPORTANT:

However, the relationship between pump efficiency and volume flow is not linear and can vary depending on the pump model and operating conditions.

In some cases, there may be an optimum volume flow. This is when the pump is at its most efficient. The efficiency may be reduced with higher or lower volume flows. Overall, the relationship between pump efficiency and volume flow is therefore an important aspect when selecting and operating a pump.

When selecting a pump, bear in mind:

- the corresponding performance characteristics

- the relevant application

- the relevant operating conditions

Taking these aspects into account optimises the efficiency and energy savings of the pump.

See also: Commissioning circulating pumps for heating systems