Faster, more precise, safer: commissioning with Wilo

Commissioning heating pumps used to be a very time-consuming and complex process. With modern technologies and smart assistant systems from Wilo, this is fundamentally no longer the case for installers like yourself. Commissioning our high-efficiency pumps is quick and precise, and you can make individual adjustments. The large colour display and the setting assistant will help you with commissioning. Or you can use our tried-and-tested Green Button Technology and the one-click commissioning with the factory settings. Getting a pump up and running has never been so easy.

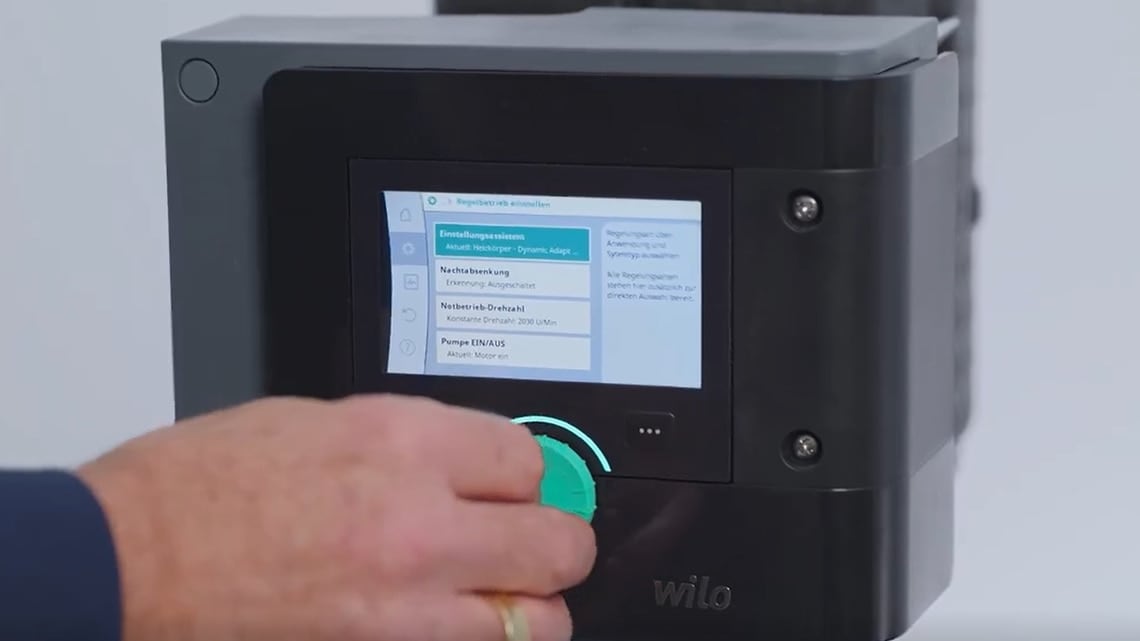

Setting assistant for perfect control

The setting assistant helps you to find the optimum control mode. It’s not always easy to select the best control mode for the relevant application. A simple method would be to set a high setpoint. But that’s not a universal solution. This setting is not energy-efficient or sustainable and can lead to excessive hydraulic supply. This could cause annoying heating noises for residents.

It’s therefore better to use our setting assistant to achieve optimum results for your customers. It makes the individual configuration of the system easier for you. With its preview feature, it guides you through a simple menu. Depending on the type of heating – whether radiator or underfloor heating, it only shows you the relevant value ranges, control modes and additional functions. This means that only the options that are actually useful for the selected application are displayed. It’s the ultimate in speed, safety and simplicity when it comes to setting a high-efficiency pump.

One-click commissioning

“One-click commissioning” is a time-saving solution from Wilo for you. One click of a button is all it takes to get the high-efficiency pump up and running with its factory settings. This means that the heating, radiator and Dynamic Adapt plus functions are set with default values.

Wilo-Stratos PICOWhat types of control are there for heating pumps?

When should you select the constant differential pressure Δp-c control mode?

When should you select the variable differential pressure Δp-v control mode?

With Δp-v or variable differential pressure, the pump reduces the delivery head by half if the flow rate in the pipe network decreases. This setting has the advantage that it saves electricity by adjusting the delivery head to the volume flow demand and a lower flow rate. Select variable differential pressure for two-pipe heating systems with radiators to reduce the flow noises at the thermostatic valves.

When should you select the constant speed n?

In the constant speed n control mode, the pump control maintains a specified speed setpoint. On most pumps, you can recognise speed positions by the numbers 1 to 3 or the Roman numerals I, II and III. The pump runs uncontrolled in three set constant speed levels. You can select this operating mode for installations with constant installation resistance that require a constant volume flow. However, this is usually not the best and most efficient choice for your customers.

When should you select the Dynamic Adapt plus control mode?

The Dynamic Adapt plus control mode independently adjusts the pump output to the requirements of the system. You don’t have to adjust the setpoint for this. Typical fields of application are consumer circuits with variable volume flows, e.g. radiators with thermostatic valves or underfloor heating systems with room control.

How to save time when commissioning circulating pumps for heating systems

Installation and commissioning of circulating pumps for the heating system

Using our instructions, it’s easy and quick for installers like yourself to professionally install the high-efficiency pumps. Here’s the link to the installation and operating instructions for our high-efficiency pumps:

Installation and operating instructions Wilo-Stratos PICOInstallation and operating instructions Wilo-Yonos PICOPower supply of the circulating pumps for heating systems

Once the heating pump is connected, it has to be supplied with power. The Wilo-Connector facilitates simple, tool-free electrical commissioning. You don’t have to open the terminal room of the module for this. Moreover, with the Wago spring clips, you don’t need any additional tools for the cable connection. The connection area is very spacious with the two-part plug housing. You can connect flexible and rigid cables with cross-sections between 3 x 1.5 mm² and 3 x 2.5 mm² with the spring clips. An integrated cable clamp ensures maximum strain relief. Locking plugs with a metal clip also prevents them from being unintentionally unplugged.

Commissioning of the circulating pumps for heating systems

Once the pump has been correctly installed in the heating system and after electrical connection, the high-efficiency pump can be commissioned.

First, open the shut-off valves upstream and downstream of the pump, which fills the pump rotor chamber with water. Then switch on the power supply. The pump now runs in factory setting.

Simple commissioning of Wilo-Stratos PICO and Wilo-Yonos PICO

Settings when commissioning the Yonos PICO from Wilo

Commissioning of the Yonos PICO is simplified by the pictograms for radiators or underfloor heating systems. A different control mode should be selected depending on the type of heating (radiator or underfloor heating).

- For radiators: Variable differential pressure.

- For underfloor heating: Constant differential pressure.

The target delivery head must then be specified. The user manual and packaging contain instructions and guidance on this.

Settings when commissioning the Stratos PICO from Wilo

The setting assistant can, for example, help you with commissioning the Stratos PICO. Here too, you are first asked about the heating system for the corresponding control mode. You can then use an editor to enter the number of radiators or the area of the underfloor heating to be heated. The pump calculates the required target delivery head from what you entered and accepts the input.

FAQs for installers

Frequently asked questions on commissioning of high-efficiency pumps for heating systems

How do I carry out hydronic balancing of the heating system with the help of the pump?

For the hydronic balancing of the heating system, you should:

- determine the pressure loss in the heating circuits,

- set the volume flow,

- set the feed temperature,

- adjust the thermostatic valves on the radiators accordingly.

The Stratos PICO supports the hydronic balancing via the function in the Wilo-Assistant app.

How do I check that the new high-efficiency pump works correctly after commissioning?

After commissioning, you should check the function of the pump by checking the room temperature, flow and pressure in the heating circuits. Make sure that the heating system is properly vented and leak-proof. Also check the pump’s current consumption to ensure that it’s functioning in the optimum operating range.

What maintenance work is required after a new high-efficiency pump has been commissioned?