How do sewage pumps work?

The harmoniously coordinated interaction of various components ensures that a sewage pump, wastewater pump or faecal pump reliably and hygienically removes the various types of sewage containing liquid and solid components. In simplified terms, a sewage pump draws in the wastewater through a suction port. In the process, an impeller inside the pump increases the flow velocity and pressure. After the impeller, the sewage is collected in a spiral housing, where the pressure is increased further, and finally led into the sewage pipe via the discharge connection.

Find the right Wilo sewage pump here

Wilo sewage pumps fulfil the strictest quality requirements in every respect while minimising energy consumption. Here you will find a selection of Wilo sewage pumps for your application.

For detached housesFor commercial buildings or multi-residential buildingsFor municipal sewage transportA sewage pump consists of the following main components:

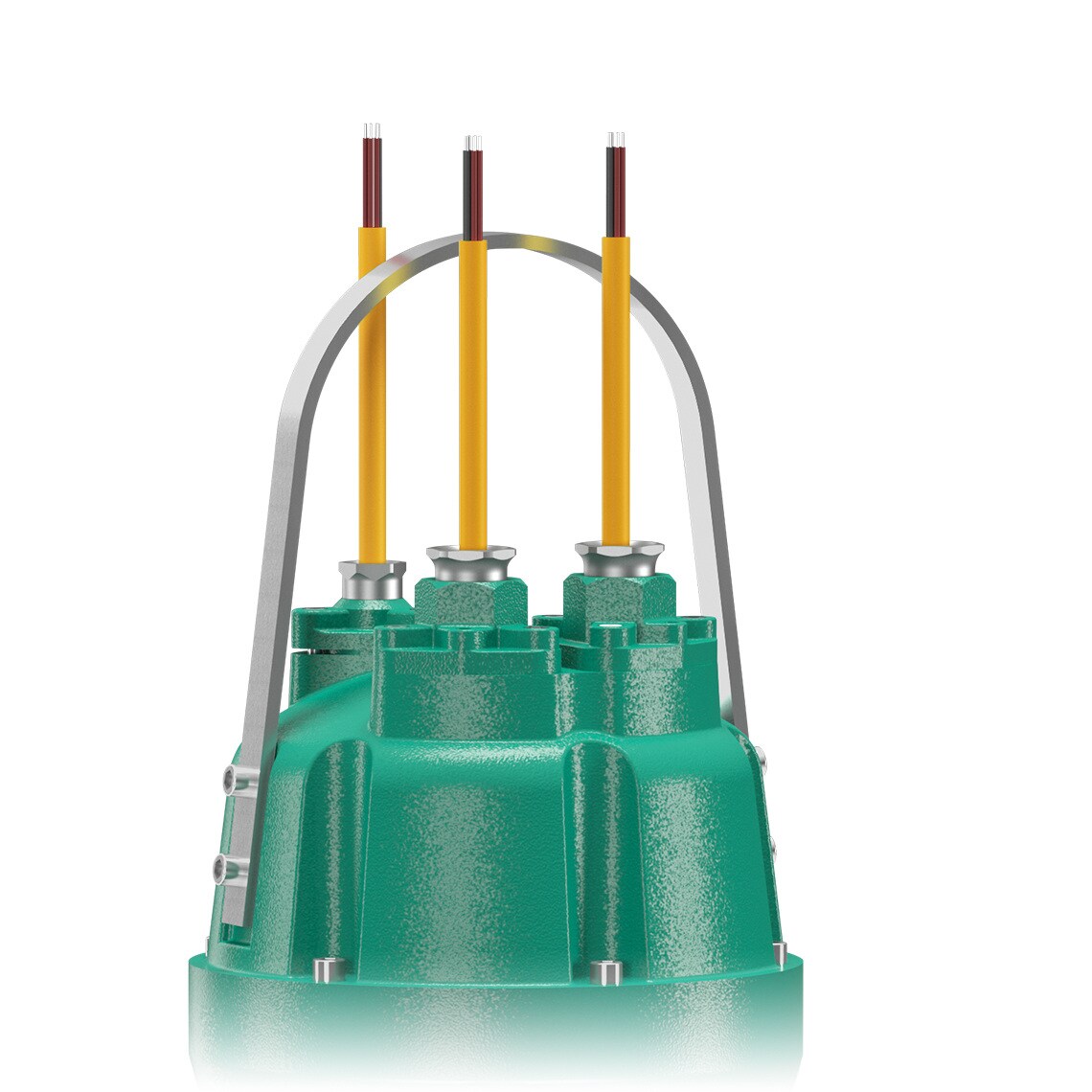

Monitoring device for a sewage pump

The monitoring devices are crucial for the safety and permanent function of your sewage pump and can trigger an alarm in case of problems or shut down the pump to prevent major damage. Wilo has developed state-of-the-art monitoring devices. You can choose different monitoring devices depending on the motor of the sewage pump: This way, the winding, the motor compartment, the sealing chamber, and even the bearing temperature can be monitored.

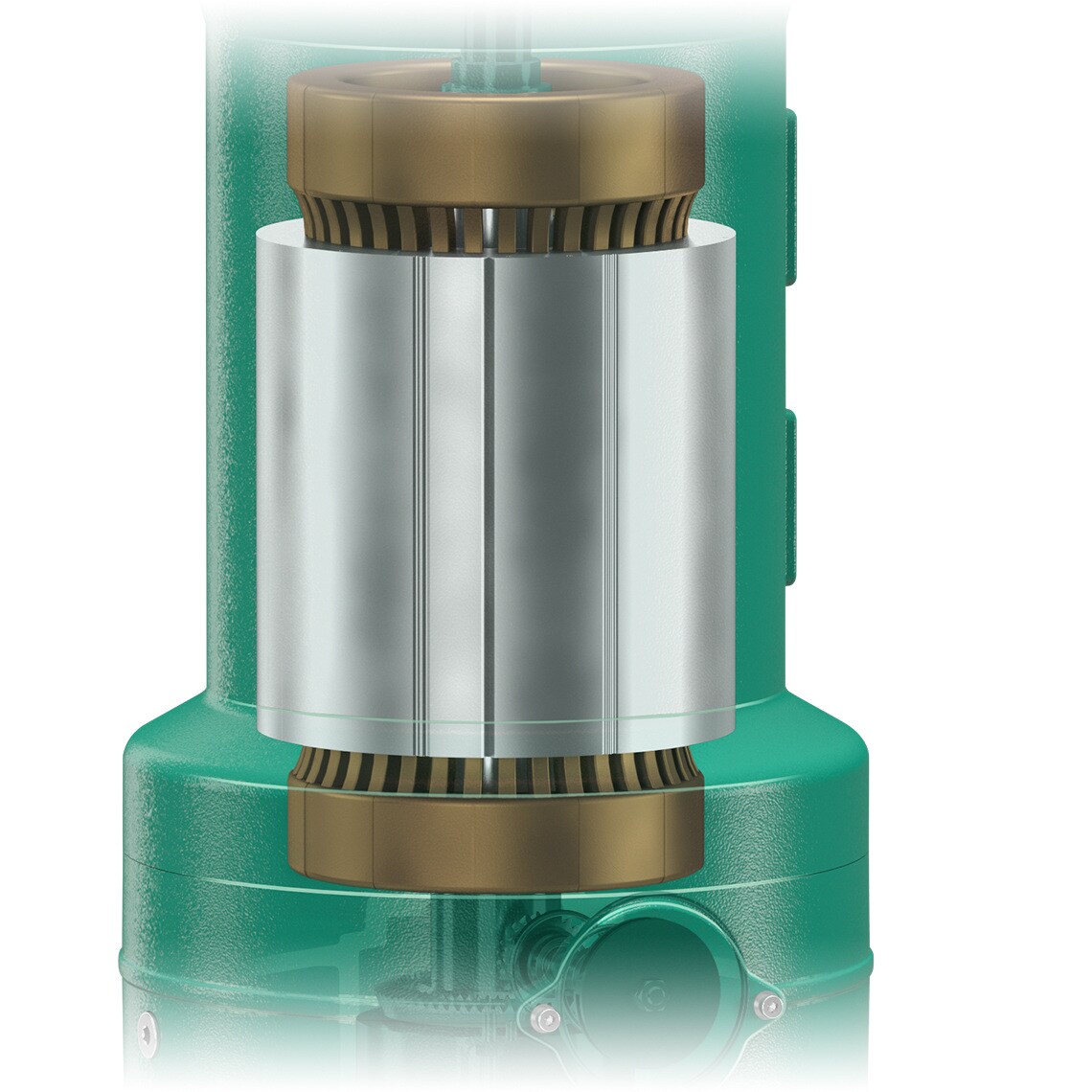

Motor of a sewage pump

The motor is the main component of the sewage pump and is responsible for driving the impeller and generating the pumping action. Depending on the desired installation type, you can choose between surface-cooled and self-cooling motors.

Wilo motors are suitable for submerged and non-immersed operation. They are notable for their high efficiency and thus optimum energy savings. Wilo offers energy-saving IE3, IE4 and IE5 high-efficiency motors in accordance with IEC 60034-30 and IEC TS 60034-30-2.

Motor seal of a sewage pump

The motor is hermetically sealed and insulated to prevent water from entering and damaging the internal components. This is because any liquid entering the motor compartment will cause a malfunction. To prevent this, there is a seal housing between the hydraulics and the motor with a seal on the motor and pump side and a gasket and leakage chamber.

Mechanical seals of a sewage pump

The function of a mechanical seal in a pump is to prevent fluid such as water, oil or chemicals from leaking out of the pump along the shaft. Mechanical seals are used in pumps that handle liquids at high pressures, temperatures or speeds. They are an important component in preventing leakage and ensuring safe and reliable operation of the pump.

Pump housing of a sewage pump

The pump housing is the outer part of the sewage pump that surrounds the impeller, the motor and the spiral housing. At Wilo, the pump housing is designed to be pressure-resistant according to the highest quality standards. The pump housing is made of a corrosion-resistant material such as cast iron.

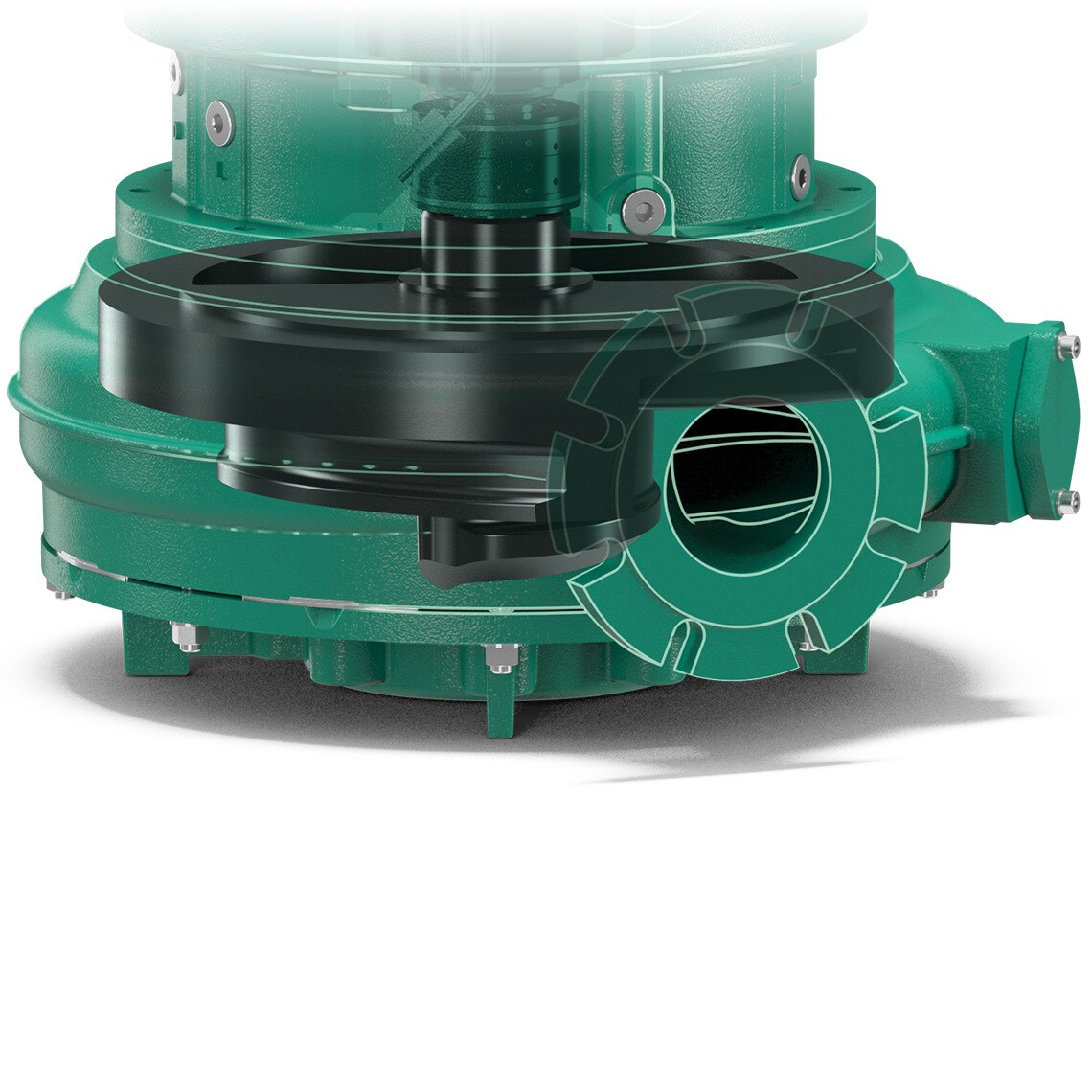

Impeller of a sewage pump

An impeller is the heart of a sewage pump. It makes sure that the sewage is pumped together with its various constituents, such as solids or faeces. Wilo has a variety of impeller shapes in its range for every application, including vortex impeller, single-channel impeller, multi-vane impeller, free-flow impeller multi-channel impeller or SOLID impeller. This means that we can tailor your sewage pump precisely to your system and take into account individual factors such as inflow conditions, delivery head and type of sewage.

FAQ – Frequently asked questions

How do impellers in sewage pumps work?

What types of impellers are there?

What material are impellers made of?

Impellers are usually made of corrosion-resistant materials that are resistant to abrasion and chemicals. The most commonly used materials for sewage pump impellers are cast iron, stainless steel and plastics such as polyamide or polypropylene. Wilo offers one of the most resistant solutions for impellers with the Ceram coating. An impeller that is resistant to corrosion and abrasion ensures that the pump operates efficiently and reliably and has a long service life.

What is the function of a sewage pump switchgear?

What do IEC 60034-30 and IEC TS 60034-30-2 mean for sewage pump motors?

IEC 60034-30 and IEC TS 60034-30-2 are international technical standards developed by the International Electrotechnical Commission (IEC). They refer to electric motors and their energy efficiency classes. The introduction of this classification helps to reduce the energy consumption as well as the associated CO2 emissions of electric motors. As electric motors are used in numerous applications, such as the industrial sector, building services and water and sewage management sectors, these standards have a significant impact on the overall energy efficiency and environmental performance of these applications. Compliance with IEC 60034-30 and IEC TS 60034-30-2 standards is important for electric motor manufacturers and their customers, as they help to reduce energy consumption and operating costs and minimise energy loss.